Section 5: robotic operation, 01 robot interface int06, 02 digital inputs and outputs – Tweco 500SP PowerMaster Automation User Manual

Page 49: Table of contents (continued), Section 5, Robotic operation -1

POWERMASTER 400SP, 500SP AUTOMATION

March 16, 2007

5-1

SECTION 5:

ROBOTIC OPERATION

5.01 Robot Interface INT06

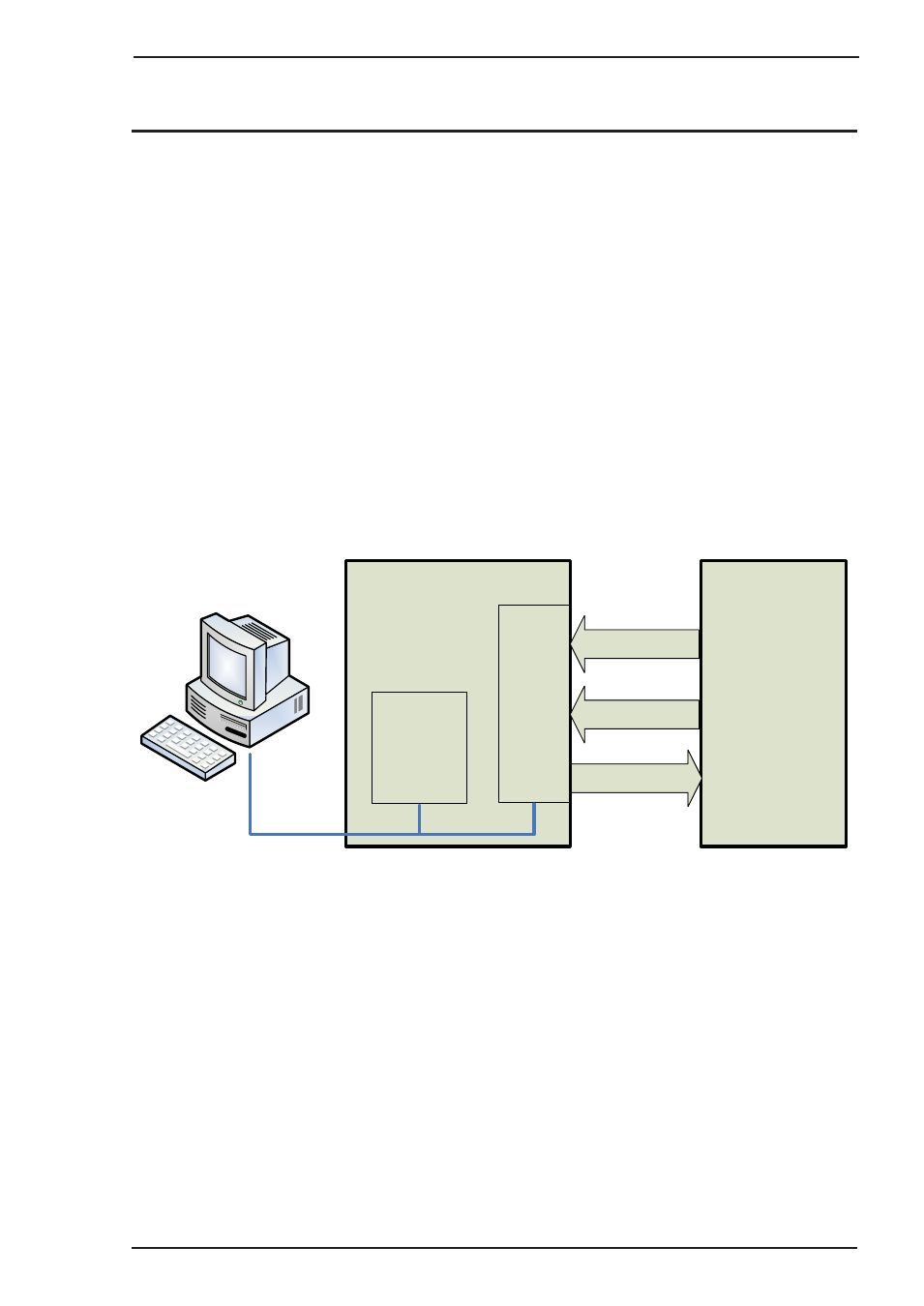

The Robot interface INT06 is for connection between the PowerMaster 400SP/500SP Automation power

sources and the robot control. There are different analog and digital in-outputs available to allow an individual

adaptation between welding power source and robot control.

Configuration of the INT06 is possible via:

• The control panel of the power source

• A PC with CAN interface

The INT06 works as a participant of the internal CAN-Bus. Commands coming over the INT06 interface are

converted into CAN-Bus messages and vice versa: actual values and status signals coming from the internal

CAN-Bus (e.g. "welding current on") are put out to the INT06 interface.

The INT06 is potentially separated from the machine. The analog and digital inputs are not potentially separated

from each other.

All inputs and outputs are available at the 42-pin Harting socket at the rear side of the welding power source.

Additional signals and functions (like gas monitoring) can be connected optionally.

Digital

Power

Source

INT06

µP

CAN-Bus

CAN-Bus

Art # A-07825

Robot Control

Analog

Digital

5.02 Digital Inputs and Outputs

The 18 digital inputs are designed for a voltage of +24V DC. For some of the digital inputs, LEDs are showing

the state of the inputs (see "Overview LEDs Robot interface INT06" on page 4).

The two digital outputs are designed as potential free relays contact. The power rating of the contacts is max.

1A at 48V. The state of the digital outputs are displayed on the pc-board INT06 with two LEDs (see " Connec-

tors on Robot Interface INT06 PC Board" on page 5-3).