Section 3: installation, 01 location, 02 transportation and positioning – Tweco 500SP PowerMaster Automation User Manual

Page 25: 03 fitting the mains cable into the cable gland, Section 3, Installation -1

POWERMASTER 400SP, 500SP AUTOMATION

March 16, 2007

3-1

SECTION 3:

INSTALLATION

NOTE

Please refer to Sections 3.08 Recommended

Equipment Setup and SECTION 4: Control

Panels for explanations of the controls.

!

WARNING

Thermal Arc advises that a suitable Mains

Plug and cable be fitted to this equipment

by a qualified electrical trades-person.

3.01 Location

Adequate air circulation is needed at all times in order

to assure proper operation. Provide a minimum of 12

inches (305 mm) of free airspace on all sides of the

unit. Make sure that the ventilator openings are not

obstructed. Ventilation airflow is from rear to side.

3.02 Transportation and Positioning

Properly transporting and positioning the equipment

is important for preventing injury. Move the equipment

in an upright position and pick a flat welding surface.

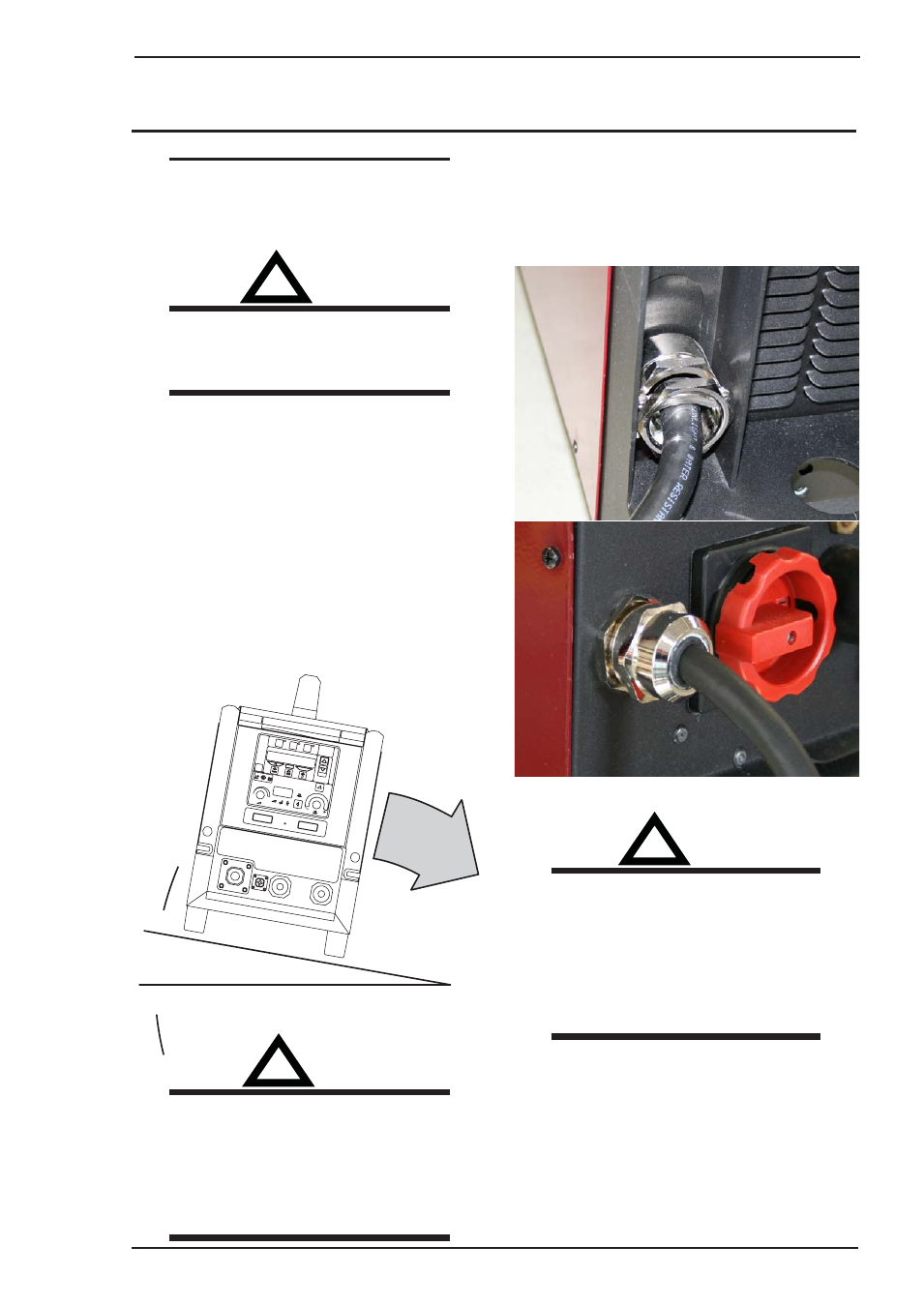

3.03 Fitting the Mains Cable into the

Cable Gland

Refer to the pictures below when connecting the

mains cable to the cable gland.

(END)

(END)

(+)

(+)

mm

mm

Save

Save

Enter

Enter

Enter

Enter

Mode

Mode

Tiptronic

Tiptronic

V

HOLD

HOLD

A

Art # A-08324_AA

Art # A-08325_AA

!

WARNING

The mains cable has to be assembled into

the cable gland as shown in the picture.

The electrical technician has to make sure

that the cable gland is adjusted to the

external diameter of the mains cable and

the mains cable is securely fastened in the

cable gland according to IEC 60974-1.

!

WARNING

Injury to the operator may occur if the

machine’s maximum permissible angle of

inclination is exceeded. The maximum

permissible angle of inclination is 10°. Only

transport or position the machine for

welding on a flat and level surface.