03 basics of pulsed arc welding, 03 basics of pulsed arc welding -4 – Tweco 500SP PowerMaster Automation User Manual

Page 64

POWERMASTER 400SP, 500SP AUTOMATION

6-4

March 16, 2007

6.03 Basics of Pulsed Arc Welding

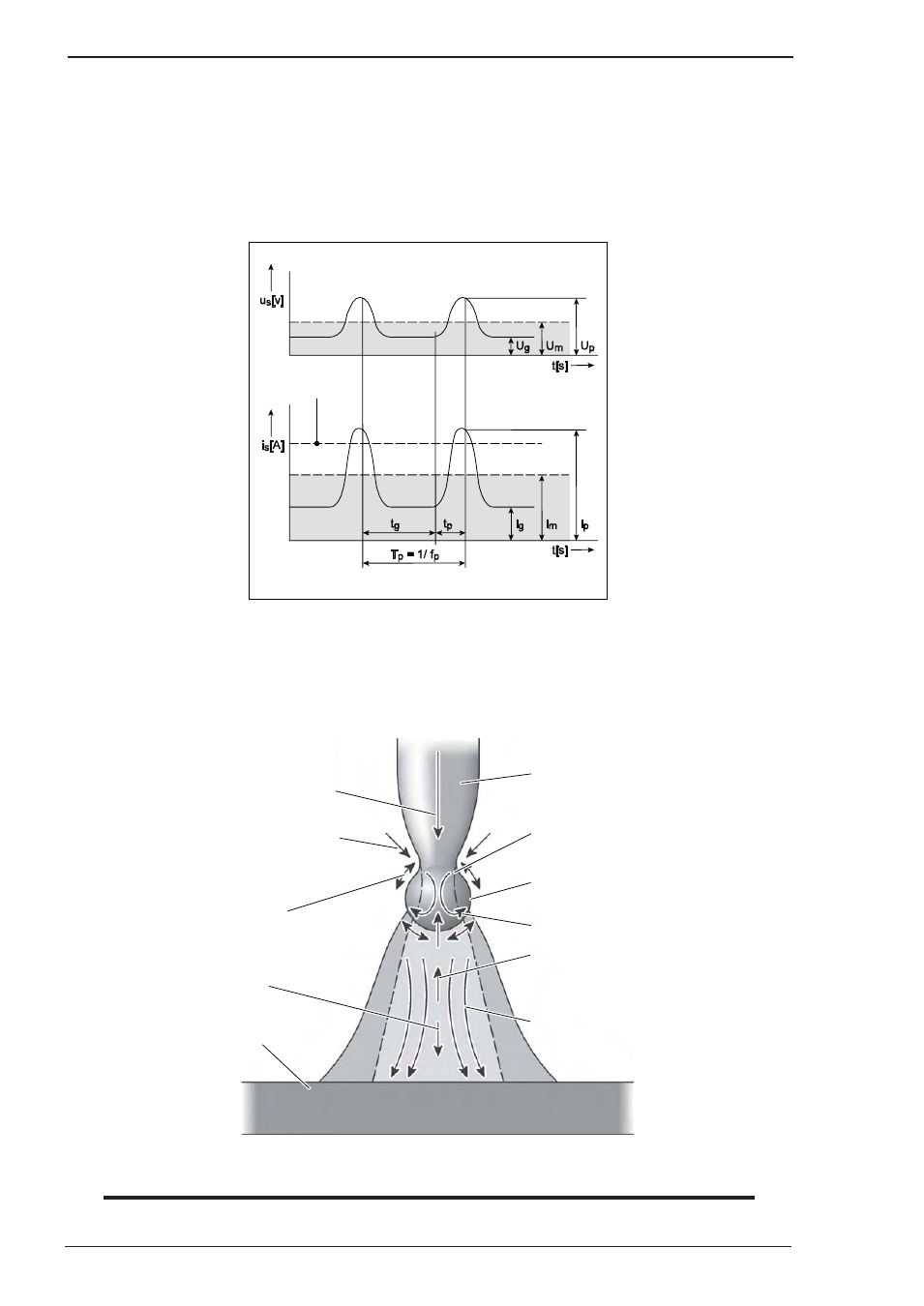

A. Current and voltage pulses

Material transfer is achieved by current and voltage pulses controlled at the same rate as the pulse frequency.

The arc power is changed by the ratio between background and pulses current, the pulse duty cycle and the

pulse frequency.

Art # A-06383

Spray Transfer

Current Range

B. Forces acting during material transfer

A number of forces come into play which influences the resulting molten metal drop formation and separation.

Electrostatic

Forces

Workpiece

Surface

tension S

Acceleration due

Electromagnetic force

F

L

(pinch effect)

Eddying forces

caused by

Forces of

repulsion (F

R

) of

evaporating

Force of inertia

Constrict drops

Viscosity

Wire electrode

to gravity

material

plasma flow

Electrostatic

Forces

Workpiece

Surface

tension S

Acceleration due

Electromagnetic force

F

L

(pinch effect)

Eddying forces

caused by

Forces of

repulsion (F

R

) of

evaporating

Force of inertia

Constrict drops

Viscosity

Wire electrode

to gravity

material

plasma flow

Art # A-06385

NOTE

The main force components for separating the drops are electromagnetic force (pinch effect).