Tweco 500SP PowerMaster Automation User Manual

Page 55

POWERMASTER 400SP, 500SP AUTOMATION

March 16, 2007

5-7

d. i. :

digital

in

p

u

t

d. o. :

digital o

u

tp

u

t

a. i. :

an

alog i

n

p

u

t

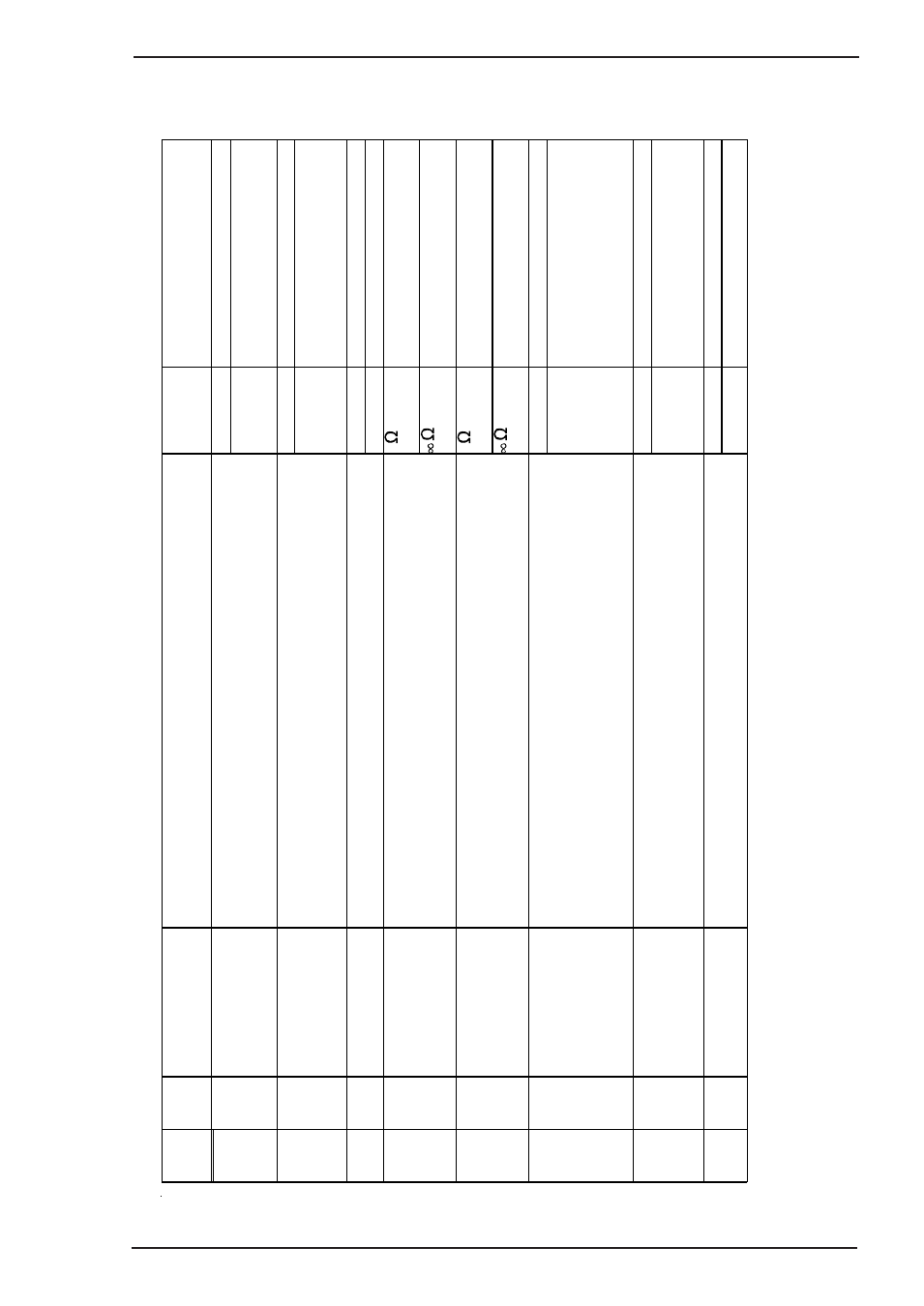

Harting Socket Pin Descriptions

Hartin

g

Pin

No

.

Ty

pe

De

sig

n

a

tio

n

De

sc

ri

ptio

n

S

ign

al

Fu

n

ctio

n

+

2

4

V

DC

bi

t = 1

1

-7

d

. i

.

job-

/

p

rog

ram

n

o.

Th

es

e di

gi

tal

in

p

u

ts

a

re

us

ed t

o

s

el

ec

t a

jo

b

n

o

. Th

e jo

b

n

o. h

as

to

be

s

et

in

to

b

in

ar

y

co

de

. W

h

en

n

o

n

e of

t

h

e

in

p

u

ts

a

re

set

(

p

rog

ram

n

o.

0

),

a

p

rog

ram

s

el

ect

io

n

ca

n

be

ma

de

at

t

h

e f

ro

n

t p

an

el

o

f t

h

e we

ld

in

g mac

h

in

e.

0

V

bi

t = 0

+2

4V

D

C

T

ipt

ro

n

ic

m

o

d

e o

n

8 d.

i.

jo

b

s

el

ec

t T

h

e

T

ipt

ro

n

ic

m

ode

is

a

cti

va

te

d

wi

th

th

is

s

ig

n

al

. A

va

lid

jo

b

n

o. ha

s to

b

e

set

at

t

h

e

in

p

u

ts

1-

7

in

bi

n

ar

y co

de

.

If the

s

ig

n

al

is

n

ot

s

et

, t

h

e

sig

n

al

s at

t

h

e di

gi

ta

l i

n

p

u

ts

1-

7

a

re i

n

te

rp

ret

ed

a

s weld

in

g

p

rog

ram

n

o.

(

o

n

ly

wh

en

DIP

s

w

it

ch 9 “

p

rog

ram

s

el

ec

t“

is

“ON“)

0V

T

ipt

ro

n

ic

mo

de of

f

+2

4V

D

C

m

ach

in

e

sta

rt

s we

ld

in

g

9 d.

i.

w

eld

in

g o

n

S

ta

rt

sig

n

al

o

f t

h

e we

ld

in

g mac

h

in

e.

Thi

s

sig

n

al

c

o

rr

es

po

n

d

s

wi

th

a

p

re

ss

ed

t

o

rch

b

u

tto

n

. Wi

th Pow

er

Ma

ste

r

S

P

ra

n

ge

t

h

e w

ir

e f

ee

d

un

it

1 i

s a

ctiv

ate

d

.

0V

m

ach

in

e

stop

s we

ld

in

g

0?

be

tw

ee

n

12

a

n

d 13

m

ach

in

e i

s op

er

ab

le

12

,1

3 d.

o

.

p

o

w

er

s

o

ur

ce

o

k

P

o

te

n

ti

al

f

ree

o

u

tp

u

t (

rel

ay

c

o

n

tact

):

if

t

h

e po

we

r

so

ur

ce

is

op

er

ab

le

t

h

e co

n

ta

ct

is

cl

o

sed,

o

the

rwi

se

t

h

e

co

n

tact

is

op

en

(i

n

ca

se of

a

n

e

rr

o

r o

r d

ur

in

g i

n

it

ia

lis

at

io

n

a

fte

r

th

e m

ach

in

e i

s

sw

it

che

d o

n

)

bet

w

ee

n

12

a

n

d 13

m

ach

in

e i

s op

er

ab

le

0?

bet

w

ee

n

13

a

n

d 14

“wel

di

n

g c

ur

re

n

t o

n

” i

s ac

ti

ve

(c

o

n

ta

ct

cl

o

sed

)

13

,1

4 d.

o

.

w

eld

in

g c

ur

re

n

t o

n

Po

te

n

ti

al

f

ree

o

u

tp

u

t (

rel

ay

c

o

n

tact

):

if

we

ld

in

g c

ur

re

n

t flo

w

s (a

rc i

s ig

n

it

ed

) t

h

e

co

n

tact

is

cl

o

sed

, if

n

o w

el

d

in

g c

ur

re

n

t (

n

o a

rc) t

h

e

co

n

ta

ct

is

op

en

be

tw

ee

n

13

a

n

d 14

“wel

di

n

g c

ur

re

n

t o

n

” i

s

n

ot ac

tiv

e

(c

o

n

ta

ct

op

en

)

+2

4V

D

C

ex

te

rn

al

m

o

d

e (

“r

ob

ot

mod

e”)

15

d.

i.

set

ex

te

rn

al

B

y

se

tti

n

g t

h

is

s

ig

n

al

, al

l

in

p

u

ts

wh

ic

h

a

re de

cl

ar

ed a

s “ex

te

rn

al

“ a

re va

lid

. Th

at

mea

ns

th

e m

ach

in

e

swit

ch

es

f

rom

“

n

o

rma

l ma

nu

al

m

o

d

e“

to

“

rob

ot

m

o

d

e“.

Wh

en

a

cti

va

te

d,

a

ll pa

ram

et

ers

wh

ich

a

re

set

a

s “ext

ern

al

“ c

an

’t be

c

h

an

ge

d ov

er

th

e

fr

o

n

t p

an

el

, b

u

t th

e a

ct

u

al

val

u

es

of the

w

el

d

in

g pa

ram

et

ers

a

re

sti

ll d

is

pl

ay

ed

.

It i

s

n

ec

ess

ar

y,

t

h

at

va

lid va

lu

es

a

re p

re

se

n

t a

t the

in

p

u

ts

at

le

as

t 1

00m

s be

fo

re a

n

d

afte

r

se

tti

n

g the

s

ig

n

al

.

0V

i

n

te

rn

al

m

o

d

e

(“

n

o

rma

l ma

nu

al

mo

de

”)

+2

4V

D

C

set

u

p mo

de

is

act

iv

e

16

d.

i.

set

u

p mo

de

B

y

se

tti

n

g t

h

is

s

ig

n

al

, t

h

e

w

el

d

in

g p

roce

d

ur

e ca

n

be

s

ta

rte

d wi

tho

u

t

sta

rti

n

g

t

h

e

pow

er

so

ur

ce

(

“c

ur

re

n

tl

ess

weld

in

g

“)

. The

s

ig

n

al

“

w

el

d

in

g c

ur

re

n

t o

n

“ i

s

sim

u

la

te

d by

t

h

e

IN

T0

4. Th

e

sig

n

al

s “

set

ex

te

rn

“,

“

set

u

p m

o

d

e“

an

d “

w

el

d

in

g o

n

“ m

us

t b

e a

ctiv

e

.

Co

ur

se co

rr

ec

ti

o

ns

ca

n

be

ma

de

in

th

is

mo

de

.

0V

set

u

p mo

de

is

n

ot ac

tiv

e

+2

4V

D

C

S

lop

e i

s a

ct

ive

17

d.

i.

sl

o

p

e Th

e

dow

ns

lo

pe

is

a

cti

va

te

d wi

th th

is

s

ig

n

al

.

DIP

s

w

it

ch 10

(

o

pe

rat

in

g mod

e

sel

ec

ti

o

n

) m

us

t b

e i

n

“ON“

p

o

sit

io

n

0V

S

lop

e i

s

n

ot

act

ive