Section 6: manual gmaw welding, 01 types of weld transfer modes, Section 6 – Tweco 500SP PowerMaster Automation User Manual

Page 61: Manual gmaw welding -1, 01 types of weld transfer modes -1

POWERMASTER 400SP, 500SP AUTOMATION

March 16, 2007

6-1

SECTION 6:

MANUAL GMAW WELDING

6.01 Types of Weld Transfer Modes

A. Dip transfer mode (short circuit arc)

This type of arc is especially suitable for thin materials

and positional welding due to a relative cool welding

pool welded with very short arc, low arc voltage and

low current. The surface tension of the welding pool

helps to draw the drop into the bath and to reignite

the arc. This cycle is repeated again and again so the

short circuit and the arcing period are constantly

alternating.

NOTE

The transition from the short circuit to

spray arc depends on the wire diameter

and the gas mixture.

B. Transitional arc

The transitional arc is especially suitable for medium

thickness sheet metals and for vertical-down welding.

The transfer of the electrode to the workpiece takes

place partly in short circuit and in free flight. Due to

fewer short circuits, the welding pool is hotter than

at the short circuit arc. Welding with transitional arc

provides higher electrode melt rate and is more

economic than welding at short circuit arc.

C. Long arc

Long arcs are typically at a higher ampere range under

carbon dioxide and gases with a high CO2 content. It

is not particularly suitable for positional welding. In

this type of arc large drops are formed which falls

into the welding pool mainly by force of gravity. This

results in occasionally short circuits occurring, which

increases the current at the moment of the short

circuit and high spatter levels when the arc is reignited.

D. Spray arc

The spray arc is not suitable for positional welding,

due to the extremely liquid nature of the welding pool.

The spraying arc forms by welding at the higher range

of ampere using inert gas or mixtures with high argon

content. The most typical characteristic of the spray

arc is the transfer of extremely fine molten metal

droplets across the arc.

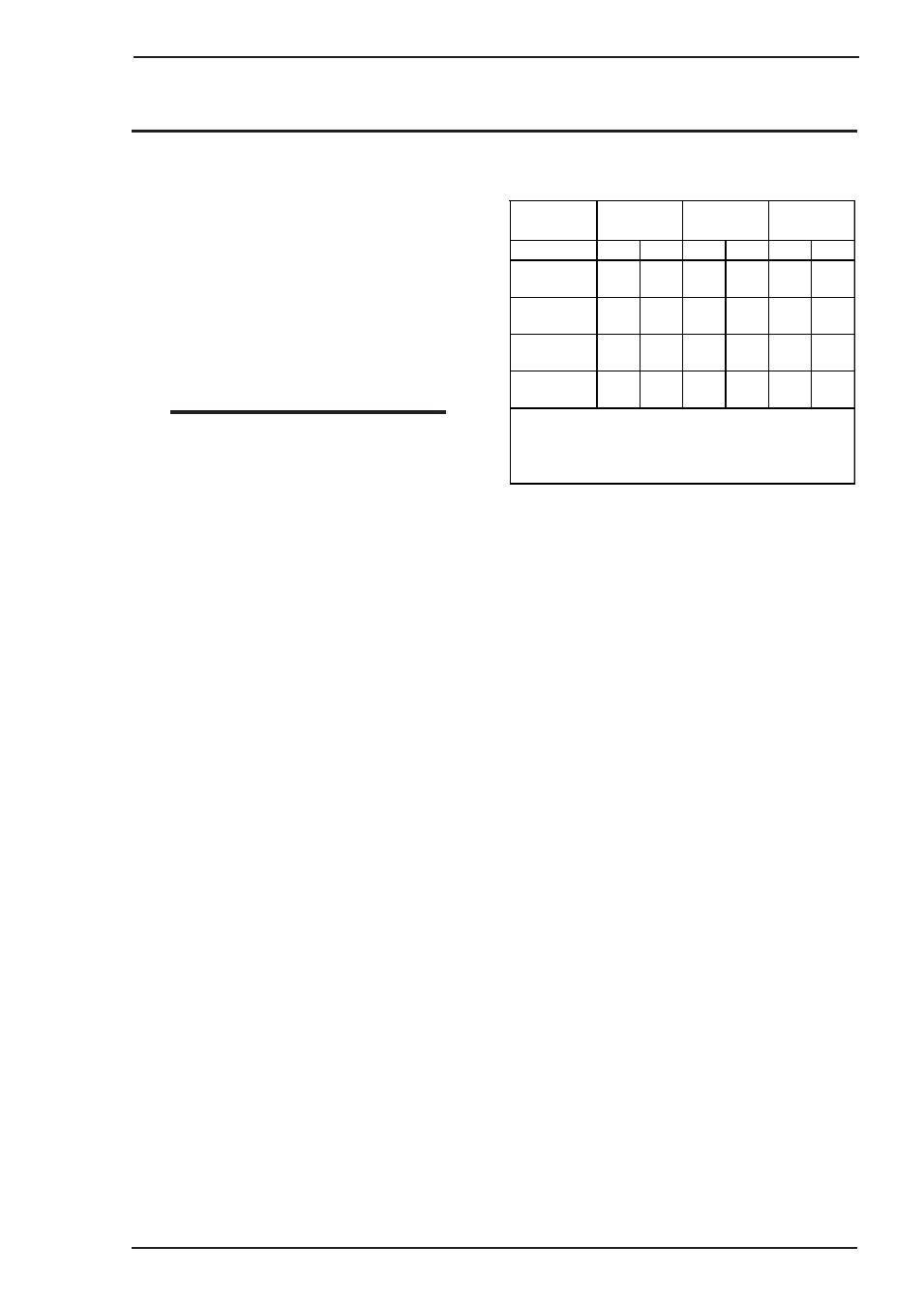

E. Working range at GMAW welding

Wire

diameter

inches

A

V

A

V

A

V

.030

140…

180

23…

28

110…

150

18…

22

50…

130

14…

18

.035

180…

250

24…

30

130…

200

18…

24

70…

160

16…

19

.045 or 3/64

220…

320

25…

32

170…

250

19…

26

120…

200

17…

20

1/16

260…

320

26…

34

200…

300

22…

28

150…

200

18…

21

Long arc /

Spray arc

Transitional

arc

Short circuit

arc

Favorable welding characteristics are only possible if voltage

and current are correctly adjusted.

CO2requires an arc voltage approximately 3 V higher than gas

mixtures with a high argon content.