03 welding process troubleshooting guide, 03 welding process troubleshooting guide -3 – Tweco 500SP PowerMaster Automation User Manual

Page 71

POWERMASTER 400SP, 500SP AUTOMATION

March 16, 2007

7-3

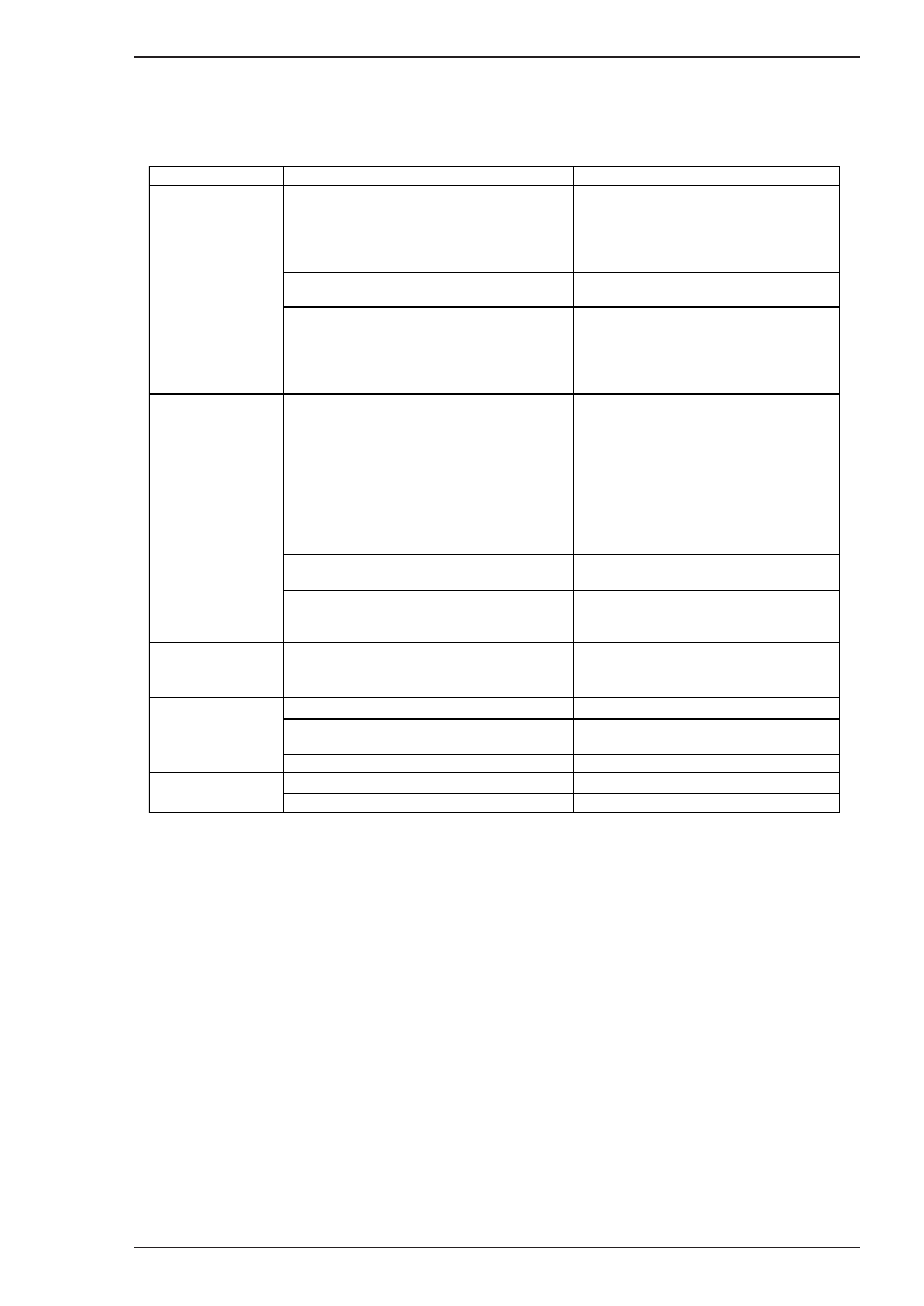

7.03 Welding Process Troubleshooting Guide

Symptom

Cause

Remedy

Gas mixture in the cylinder has separated due to lack

of use

Place protective cap used for storage and

transport on cylinder then carefully disconnect

the cylinder from the welder and lay it down on

the floor. Carefully roll it back and forth to re-

mix the gas

Wire is contaminated with oil or the wire quality is

uncertain

Contact wire manuafacturer / supplier.

Keep the wire covered

Work piece is contaminated with grease or oil

Degrease with mineral spirits, etc to remove

contaminates

Poor current transfer to the wire at the contact tip

Use a copper or brass jump liner in the

conductor tube to improve current transfer to

the wire

Stanless steel weld has

a dark burnt finish

Arc length control (58) has been adjusted too high

Reduce arc length, control (58)

Inadequate gas coverage

Increase gas flow by 10% and check again.

Shield arc from drafts.

Hold nozzle closer to the work.

Replace the damaged nozzle to center contact

tip in nozzle

Wire is contaminated with oil

Contact wire manuafacturer / supplier.

Keep the wire covered

Work piece is contaminated with grease or oil

Degrease with mineral spirits, etc to remove

contaminates

Poor current transfer to the wire at the contact tip

Use a copper or brass jump liner in the

conductor tube to improve current transfer to

the wire

Weld performance is

very poor or high

spatter levels

Incorrect wire / gas combination selected

Set the correct gas / wire combination

Improper work lead connection

Reconnect work lead

Contact tip is worn with an oval shape hole or

contact tip is black

Replace contact tip

Contact tip is loose

Tighten contact tip

Material build-up in torch liner

Replace torch liner

Contact tip is worn or damaged

Replace contact tip

Varying arc length

when welding

Poor edge wetting on

stainless steel welds

Dirty aluminum welds

Poor weld starts