03 menu structure, 03 menu structure -4 – Tweco 500SP PowerMaster Automation User Manual

Page 40

POWERMASTER 400SP, 500SP AUTOMATION

4-4

March 16, 2007

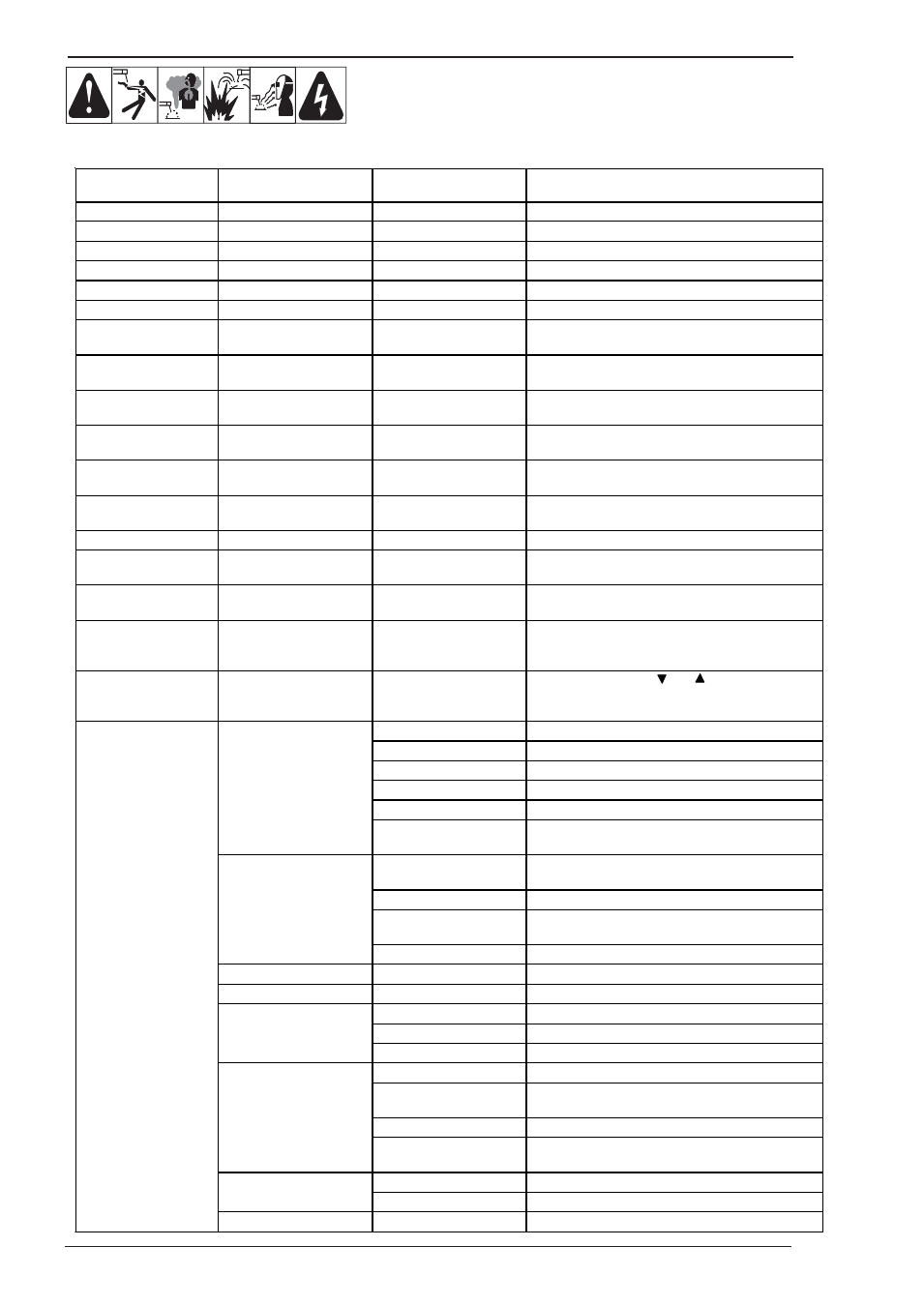

4.03 Menu Structure

Main Menu

Level 1 “Extras”

Level 2

Remark

Gas pre-flow

0

–

10

sec.; not in SMAW/STICK electrode process

Start current

20

% – 200 % of the welding current

Start current time

0 – 10 sec.; not in 4-stroke (4T) mode

Twin pulse frequency

0,5 – 5 Hz; only in TwinPulse mode

Twin pulse current change

5

–

50

% of the welding current; only in TwinPulse process

Twin pulse relation

20

% – 80 %; only in TwinPulse process

Welding current

Adjustment range depends on the selected material-wire-

gas combination

Downslope

10

–

990

A/sec.; not in SMAW/STICK process, only when

downslope = on

Crater fill current

10

% – 200 % of the welding current; not in SMAW/STICK

process, only when slope = on or in 4 (4T) stroke

Crater fill time

0 – 10 sec.; not in SMAW/STICK process, only for slope =

on

Wire burnback

time

20

% – 300 % of the programmed value; not in

SMAW/STICK process

Gas post-flow

20

% – 200 % of the programmed value; not in

SMAW/STICK process

Arc length correction

60

% – 140 % of the programmed value

Inductor

effect

20

% – 200 % of the programmed value; only in

ManualGMAW process (short arc)

Arc dynamic arc force

0

% – 100 % of the programmed value; only in

SMAW/STICK process

Job selection, indication of

set and job name

Set and job name are indicated only in Tiptronic mode upon

actuation of the „TT Enter“ push-button (47) or the

„Tiptronic“ push-button (49)

Edit

mode

for set and job

name

Move the cursor with the

and

push-buttons (51);

change the character with the pushbuttons (48) (+) and

(44) (-)

Operating system Master Version number, operating system Master

Operating system Process Version number, operating system process

Operating system DMRs Version number, motor assembly

Welding program version Version number, welding programs

Operating hour counter

Indication of the welding duration in h, min, sec

1 Machine data

Configuration Machine type and the recognized power module (with max.

current ) are indicated alternately

Last error message Indication of the last three error messages from the error

memory (0 = last error, 2 = oldest error)

Module temperatures Temperatures of the power modules in °C

Operating voltages

Indication of the operating voltages (15 V

/ 24 V) of the

assembly DPMAPRO

2 Diagnosis

Flow rate, cooling unit Indication of the coolant flow rate in l/min

3 Language

Selection of the menu language

4 Display contrast

Contrast setting of the LCD display

0 normal cooling unit switches on, as soon as an arc is ignited

1 on cooling unit runs constantly

5 Mode cooling system

2 off

cooling unit is deactivated

0 All

welding controls can be adjusted by user

1 Only Tiptronic on/off and job selection can be adjusted by

user

2 Tiptronic on/off, job selection free

6 Lock function

3 All

welding controls locked except menu selection, gas and

pump test

Voltage correct arc length with rotary pulse encoder (58)

7 Arc length control

Wire correct wire speed with rotary pulse encoder (58)

Extras

8 Robot interface

Menu item is only visible when the machine is equipped