Tweco Weld Sequencer User Manual

Page 60

APPENDIX

54

Manual 0-2023

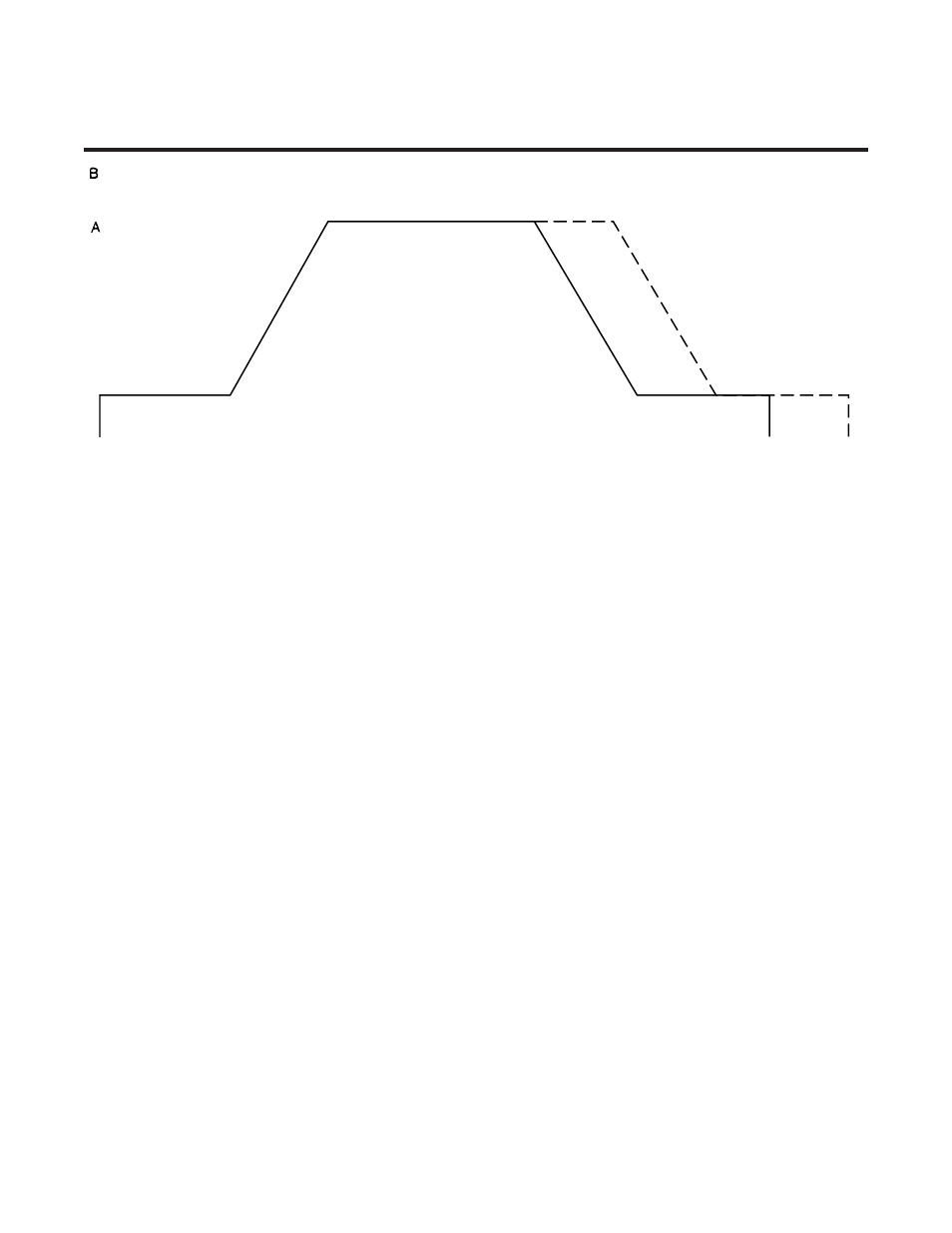

APPENDIX VI: TIMING AND SEQUENCE OF OPERATION

FOR WELD SEQUENCER (ALL MODELS)

A

• Power Supply to ON

• Weld Console in RUN position

• Coolant Recirculator to ON

• Gases on

• Torch positioned

• Weld Sequencer Enclosure to ON

• RP1 Control CONTACTOR to ON

• All other control modules to ON

B

• RP1 START SEQUENCE pressed

• CP1 starts pulsing current

• CS1 INITIAL CURRENT starts timing

• CC Relay de-energized

• AL Relay energized

C

• CS1 INITIAL CURRENT times out and Signals:

CS1 UPSLOPE to start

GS1 UPSLOPE to start

WT1 to start timing

D

•Peak current is reached

• Peak plasma gas flow is reached

• AL Relay de-energized

A

B

C

D

E

A-02437

E

D

H

D

G

D

I

D

G

I

H

E

• WT1 times out and Signals:

CS1 to start downslope

GS1 to start downslope

AL Relay energized

E

D

• CS1 downslope delayed X seconds

• GS1 downslope delayed X seconds

G and G

D

• Current reaches FINAL level

• Gas flow reaches MIN flow level

• FINAL CURRENT starts timing

H and H

D

• FINAL CURRENT times out

• CC Relay energized

• Main Contactor opens

• Welding Arc extinguishes

I and I

D

• RP1 CONTACTOR to OFF

• All control modules to OFF

• Weld Sequencer Enclosure to OFF

• Welding Console to OFF

• Power Supply to OFF

• Coolant recirculator to OFF

• Gases shut off