Tweco Weld Sequencer User Manual

Page 41

Manual 0-2023

35

Section Name

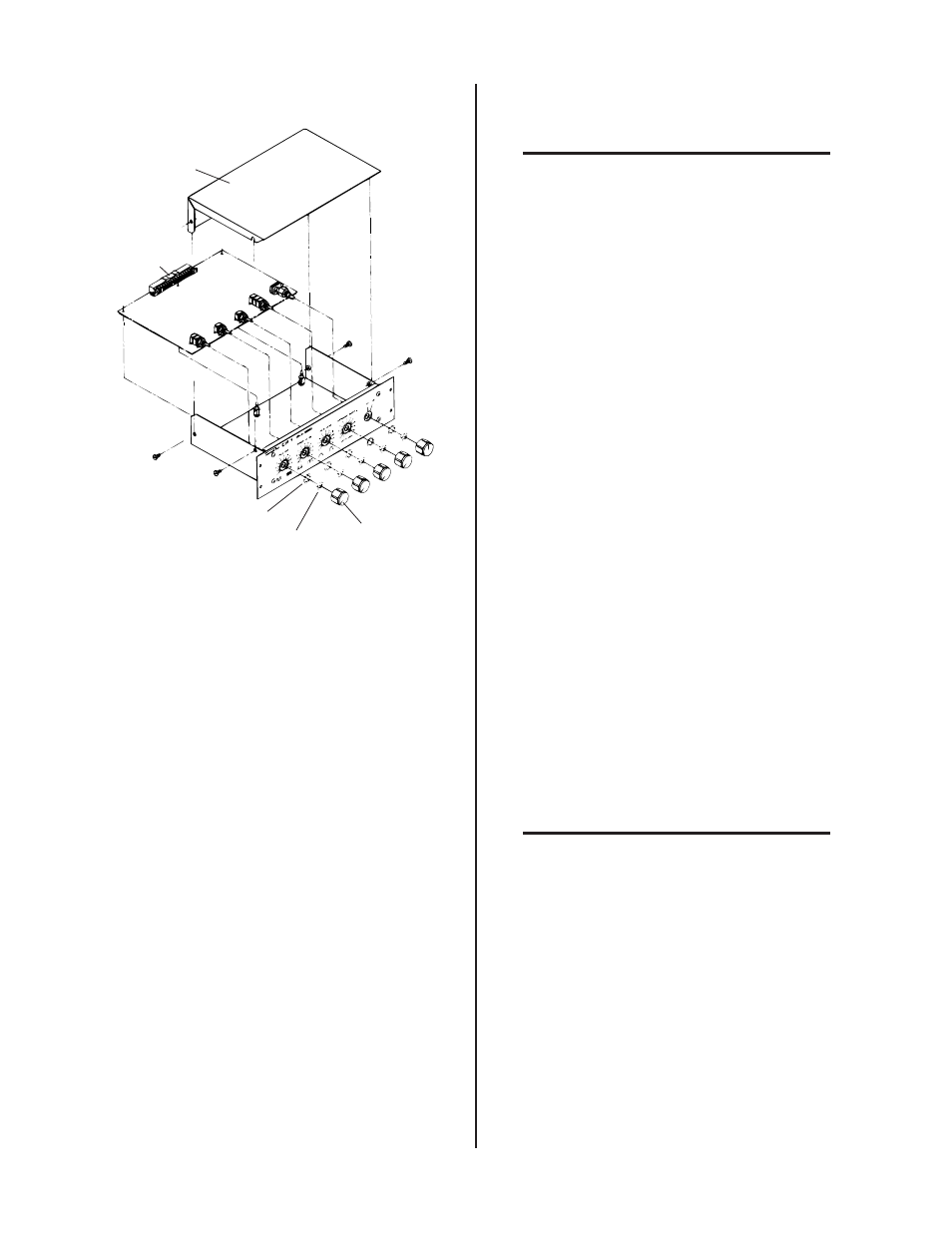

A-02440

Knob

Hex Nut

Washer

PC Board

Connector

Cover

Figure 5-4 Typical PC Board Removal

4. Remove all the hex nuts securing Figure 4-D Typical

PC Board Removal (CP1, CS1 and GS1)

5. Press the locking tab on each PC board support and

raise the board past the locking position to allow re-

moval of the board.

6. Install the PC board (component side up) into the

switch mounting holes in the front panel. Press the

board down onto the supports until it snaps into the

locking tabs.

7. Secure the switches to the front panel with supplied

hex nuts.

8. Position knobs on the flats of the switch shafts and

push on.

9. Connect plug(s) to connector(s).

10. Replace module cover and secure.

D. GS1 Motor/Valve/Pot Assembly

Replacement

NOTE

Refer to Sections 6.04 and 6.05 for parts list and

overall detail drawing.

The main components of the Motor/Valve/Pot Assem-

bly are replaceable. These include the motor assembly,

valve assembly, pot assembly, pinion gear, and coupling.

The assembly can also be purchased complete. Replace-

ment of the components require that GS1 be removed

from the Weld Sequencer. Proceed as follows:

1. Disconnect all power to the welding system.

2. Remove cover or side panels (enclosure extension).

3. Remove the two welding console plasma gas hoses

from the rear of the Weld Sequencer Enclosure. Re-

move the four screws holding the GS1 gas hose con-

nectors to the Enclosure rear panel.

4. Remove connector from the rear of GS1.

5. Remove the four screws securing GS1 to the front of

the Weld Sequencer Enclosure.

6. Slide GS1 out of the Weld Sequencer Enclosure.

7. Remove the cover from GS1.

8. Disconnect the two connectors (motor and pot) on the

Motor/ Valve/Pot Assembly.

9. Remove the four screws securing the Assembly to the

GS1 rear panel.

If the complete Motor/Valve/Pot Assembly is to be

replaced go to Section 5.05-H.

E. Coupling, Pinion Gear, Pot Assembly and

Motor Assembly Replacement

NOTE

Refer to Section 6.05 for parts list and overall de-

tail drawing.

1. If the motor assembly is to be replaced loosen the two

1/16" hex set screws securing the coupling to the

motor assembly. If the coupling or pinion gear is to be

replaced loosen the two 1/16" hex set screws secur-

ing the coupling to the pinion gear.

2. Remove the four screws from the motor assembly and

remove the motor and coupling, leaving the pinion

gear in place