04 test procedures, A. checking wt1, B. checking contactor control – Tweco Weld Sequencer User Manual

Page 39: C. checking current control

Manual 0-2023

33

Section Name

R. Using RP1 and CP1, spot welds are erratic with

varying penetration

1. CP1 on during spot welding

a. Turn CP1 to OFF

When the CS1 FINAL TIME times out the CC relay is

energized, opening the circuit to the main contactor in

the power supply. Welding arc is extinguished.

S. Welding arc does not extinguish

1. CC relay faulty

a. Replace relay

2. CS1 PC Board faulty

a. Replace

At the end of the weld the RP1 CONTACTOR switch is

moved to the OFF position first to open the main con-

tactor in the power supply. Then the Weld Sequencer

Enclosure is turned OFF along with the other compo-

nents of the system.

T. Welding arc transfers when CS1, WT1 or Weld

Sequencer is turned OFF

1. RP1 CONTACTOR switch not OFF

a. Move RP1 to OFF

5.04 Test Procedures

WARNING

Some tests involve voltage measurements made

with power ON. Tests requiring voltage measure-

ments are marked with this warning symbol. All

other tests are to be made with the primary system

power turned OFF.

The following tests are suggested for specific problems

listed in the troubleshooting guide. Letter designations

correspond to those listed in the remedy area of the guide.

A. Checking WT1

To test WT1 move the torch to about 1 inch (25.4 mm)

above the workpiece. Arc will not transfer but the gas

should go through the upslope sequence to max flow and

start to downslope at the end of set weld time (or at end

of downslope delay time). If this does not happen WT1

is faulty and must be replaced.

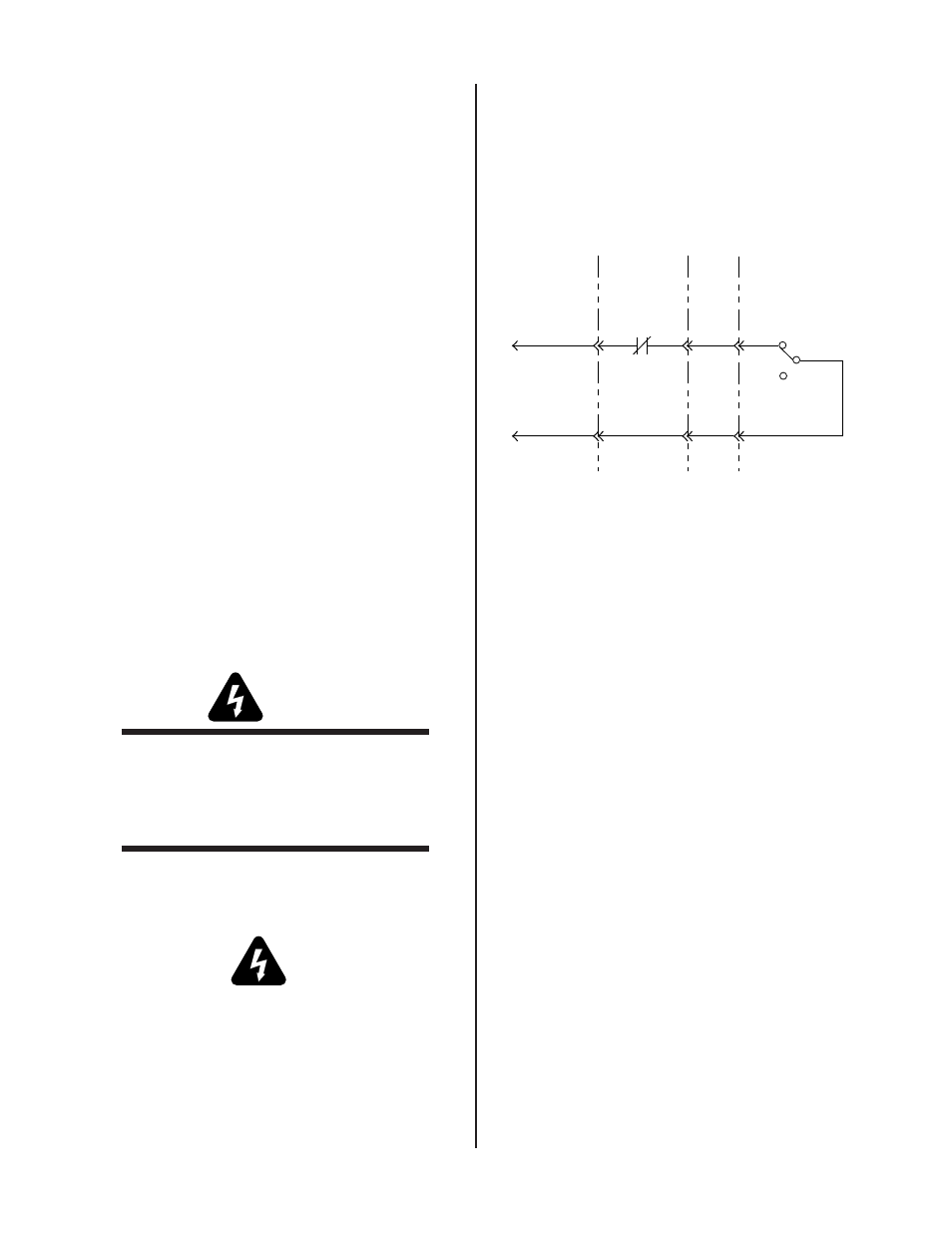

B. Checking Contactor Control

With the Weld Sequencer in OFF position and the RP1

CONTACTOR switch ON. Use an ohmmeter to check

for continuity from black to white/brown wires on the

console P/S cable J5-4 and J5-5. If there is no continuity,

check each component and wire in the contactor control

circuit diagram.

Black

White/Brown

A-02438

CC

ON

OFF

Contactor

26

28

28

26

27

J5-4

J5-3

J6-4

J6-3

J9-4

J9-3

Console/Power

Supply Control

Cable

Weld

Sequencer

Enclosure

Remote

Control

Cable

RP1

Figure 5-2 Contactor Control Circuit Diagram

C. Checking Current Control

With CS1 and CP1 turned OFF or J8 and J7 connected to

the jumper plugs and RP1 CURRENT CONTROL set to

minimum, check for continuity (approximately zero

ohms) from J5-7 (red wire) to J5-13 (blue wire), (refer to

Figure 5-3) with an ohmmeter set on “times 1000” scale.

Check for 10K (10,000) ohms from J5-7 to J5-1. Setting

RP1 CURRENT CONTROL to maximum will reverse the

readings (zero ohms between J5-7 and J5-1, and 10K ohms

between J5-7 and J5-13). If proper readings are not ob-

tained check individual wire connections and components

to identify the fault.