08 gs1 gas slope control descriptions, Figure 4-7 gs1 gas slope – Tweco Weld Sequencer User Manual

Page 29

Manual 0-2023

23

OPERATION

EXAMPLE

A Power Supply set in a range of 50 - 150 amps

with a background current of 30% would be 150 -

50 = 100 amps total range 100 amps x 30% = 30

amps 30 amps + 50 amps min = 80 amps back-

ground.

B a ck gr o u n d C u r r e n t

A - 0 2 4 2 9

;;;;

To adjust background current with an ammeter while

doing a test weld, pull the knob out. CP1 will cease to

pulse and will maintain weld current at background

current level. Adjust to new background current by

turning knob (checking ammeter on console or power

(supply). Push back in to resume pulsing operation.

NOTE

An auxiliary connection is available to start or stop

the CP1 without stopping the weld sequence (see

AVC LOCKOUT, refer to Section 3.09).

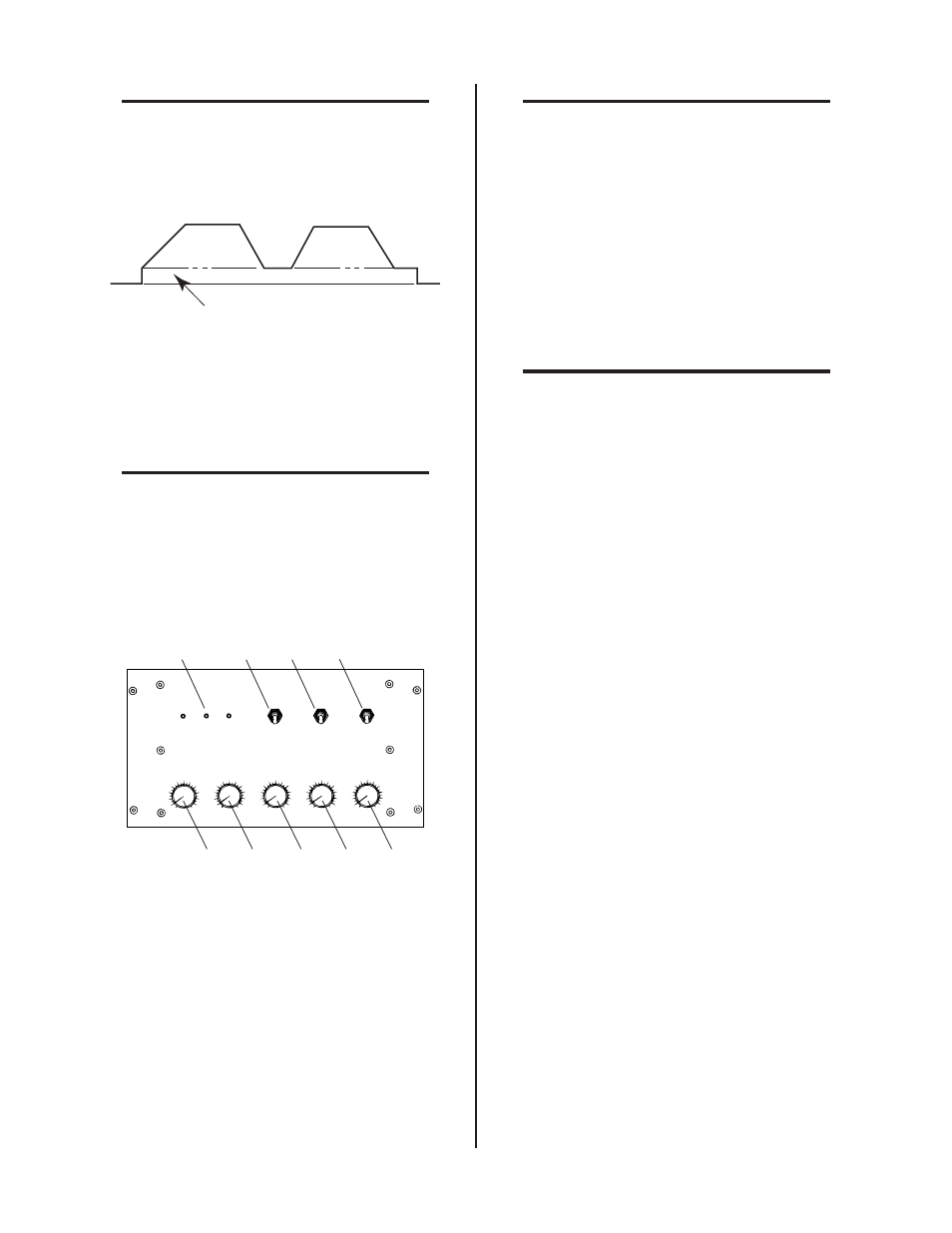

4.08 GS1 Gas Slope Control

Descriptions

GS1

GAS SLOPE

M I N

G A S F L OW

. 5 - 3 S C F H

. 2 5 - 1 . 4 l p m

M A X

G A S F L OW

2 - 7 S C F H

1 - 3 . 3 l p m

0

1

2

3

4

5

6

7

8

9

1 0

0

1

2

3

4

5

6

7

8

9

1 0

U P S L O P E

R AT E

0

1

2

3

4

5

6

7

8

9

1 0

D OW N S L O P E

R AT E

0

1

2

3

4

5

6

7

8

9

1 0

D OW N S L O P E

D E L AY

( 0 - 1 0 s e c . )

0

1

2

3

4

5

6

7

8

9

1 0

A - 0 2 4 2 0

G A S F L OW

M I N

S L O P I N G

M A X

U P

D OW N

M A N UA L

AU TO

O N

O F F

1

2

3

4

9

8

7

6

5

Figure 4-7 GS1 Gas Slope

1. ON/OFF Switch

In OFF position GS1 is disabled and gas flow remains

at its last setting. The ON position energizes its cir-

cuitry.

2. MANUAL/AUTO Switch

MANUAL position allows the operator to manually

control gas slope sequence for setup and also during

the welding operation.

NOTE

CS1 will not operate with GS1 in MANUAL posi-

tion. In AUTO position the gas slope sequence will

automatically be controlled by signals from the CS1

Control circuitry only.

3. UP/DOWN Switch

With the MANUAL/AUTO switch in MANUAL po-

sition the UP/DOWN switch (see NOTE) is used to

start upslope (UP) and downslope (DOWN) of gas

flow. The rate of slope is determined by the sloping

control settings. In AUTO position, the UP/DOWN

switch is disabled.

NOTE

Refer to Section 4.04, RP1 Control, for Remote

Up/Down Control.

4. GAS FLOW MIN/SLOPING/MAX LED

These three LEDs light to indicate the status of gas

flow during a weld.

5. MIN GAS FLOW Control

Adjusts minimum gas flow rate, 0.5 - 3 scfh (0.25 - 1.4

lpm). The numbers surrounding the knob are refer-

ence points only and have no set value.

6. MAX GAS FLOW Control

Adjusts maximum gas flow rate, 2 - 7 scfh (1 - 3.3 lpm).

The numbers surrounding the knob are reference

points only and have no set value.

7. UPSLOPE RATE Control

Controls the rate (time) for gas flow to increase from

minimum flow to maximum. This is done by trial

and error in pre-setup. The numbers surrounding the

knob are reference points only and do not indicate

time (0 slowest, 10 fastest). Refer to Figure 4-10 for

details.

8. DOWNSLOPE RATE Control

Controls rate (time) for gas flow to decrease from

maximum flow to minimum. This is done by trial and

error in pre-setup. Numbers surrounding the knob

are reference points only and do not indicate time (0

slowest, 10 fastest). Refer to Figure 4-10 for details.

9. DOWNSLOPE DELAY Control

Allows the start of gas downslope to be delayed for a

predetermined amount of time (0 to 10 seconds) after

downslope is initiated either manually or by WT1.

Numbers surrounding the knob correspond to sec-

onds.