D. wt1 weld timer, E. gs1 gas slope, Figure 4-9 adjusting cp1 controls – Tweco Weld Sequencer User Manual

Page 32

OPERATION

26

Manual 0-2023

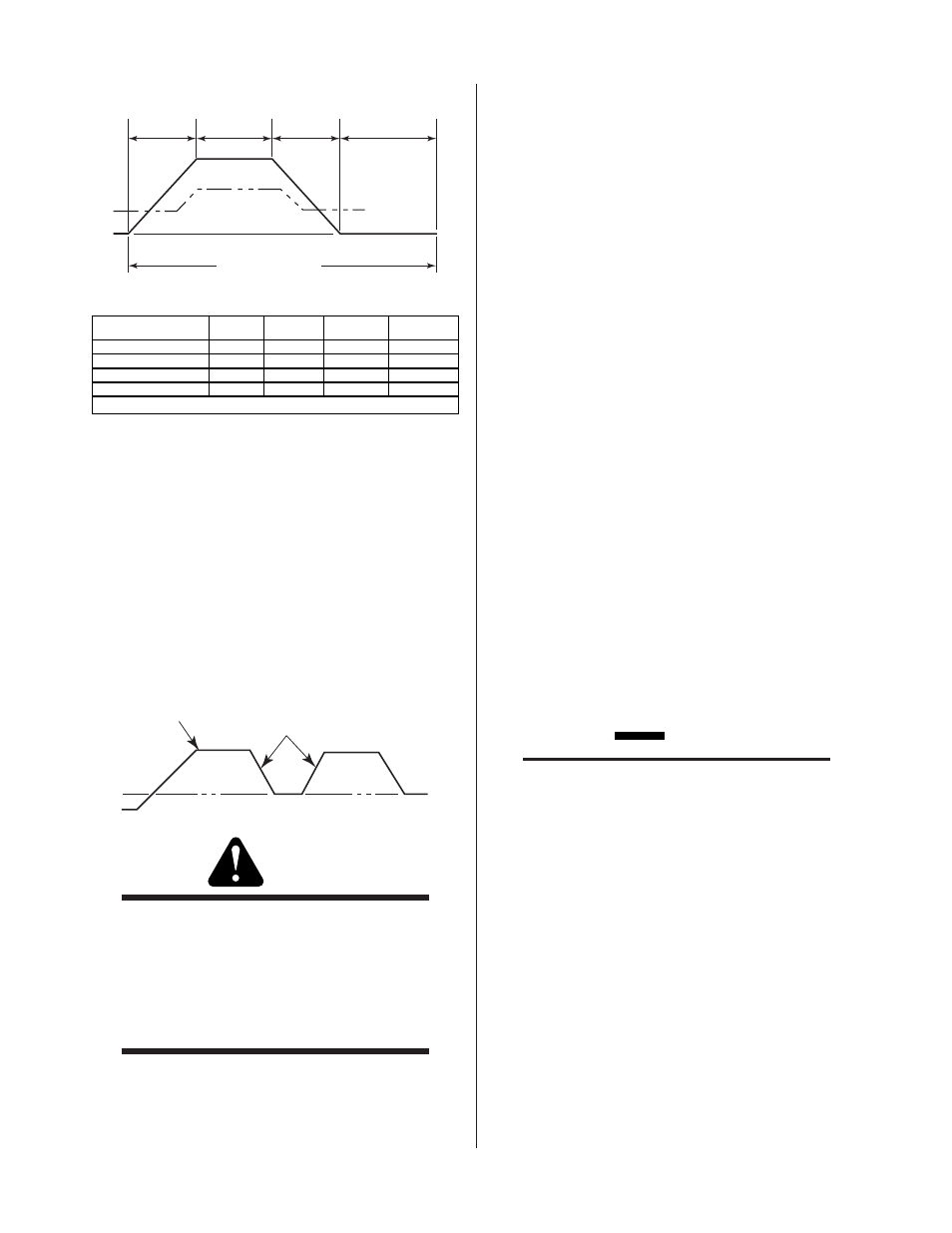

SLOPE

Time

ON Time

(Peak Current)

SLOPE

Time

ON Time

(Background Current)

Peak Current

Background Current

Minimum Current

A-02434

Total Pulse Time

By Increasing

On-Time

(Peak)

Slope Time

On-Time

(Background)

Total Pulse

Time

PULSE RATE

Decreases

Unchanged

Decreases

Decreases

PERCENT ON TIME

Increases

Unchanged

Decreases

Unchanged

PULSE SLOPE

Unchanged

Decreases

Unchanged

Decreases

BACKGROUND CURRENT

Unchanged

Decreases

Unchanged

Decreases *

* = No change when Slope Rate set at MAX

Figure 4-9 Adjusting CP1 Controls

4. Determine necessary background current and calcu-

late the percent of the power supply range setting as

done for CS1 INITIAL CURRENT. If the welding con-

sole has an ammeter, while welding, set by pulling

the BACKGROUND CURRENT knob out and rotate

the knob until the desired amperage is read on the

ammeter. Push the knob back in.

5. While making a sample weld, adjust the PULSE SLOPE

control knob until the desired rate of change between

background and peak current is achieved.

Pe a k C u r r e n t

P u l s e S l o p e

B a ck gr o u n d C u r r e n t

A - 0 2 4 3 5

WARNING

The RP1 Control CONTACTOR ON/OFF switch

must be in the OFF position before the Weld Se-

quencer Enclosure or any control module is shut

OFF. If this is not done and the torch is close

enough to the workpiece (or ground) when the

welding system is energized an arc transfer can

occur.

D. WT1 Weld Timer

WT1 controls weld time from the start of upslope to the

start of the downslope (timed out) sequence when CS1 is

used. Calculate or determine the time by timing the se-

quence during a test weld.

When WT1 is used to time spot welds determine the 'time

on' of the weld. Contactor closure will activate the timer

for each spot weld. Make sure to shut CS1 off when spot

welding.

1. Set the SECONDS-TENTHS dial to the required weld

time.

2. Move the ON/OFF switch to the ON position to acti-

vate the timer.

3. Activate the RP1 CONTACTOR ON switch. One spot

weld sequence will be completed.

4. Press the RP1 SPOTWELD switch as required for ad-

ditional welds.

E. GS1 Gas Slope

1. Make sure plasma gas supply is turned on.

2. Make sure the welding console is in SET mode and

power is ON.

3. Move the GS1 ON/OFF switch to ON position.

4. Move the GS1 MANUAL/AUTO switch to MANUAL

position.

5. Move the GS1 UP/DOWN switch to DOWN position

(momentary)

CAUTION

Minimum sloping and maximum gas flow rates

must stay within the acceptable range of the cur-

rent at each point to prevent tip damage (gas flow

too low) or cutting action (gas flow too high).

6. Adjust the MIN GAS FLOW knob until the required

minimum plasma gas flow rate is shown on the weld-

ing console flowmeter.

7. Move the GS1 UP/DOWN switch to UP position (mo-

mentary).

8. Adjust the MAX GAS FLOW knob until the required

maximum plasma gas flow rate is shown on the weld-

ing console flowmeter.

9. Adjust GS1 UPSLOPE RATE to correspond to current

upslope rate (if CS1 is used) or to achieve the desired

rate refer to Figure 4-10.