Section 4: operation, 01 introduction, 02 functional overview – Tweco Weld Sequencer User Manual

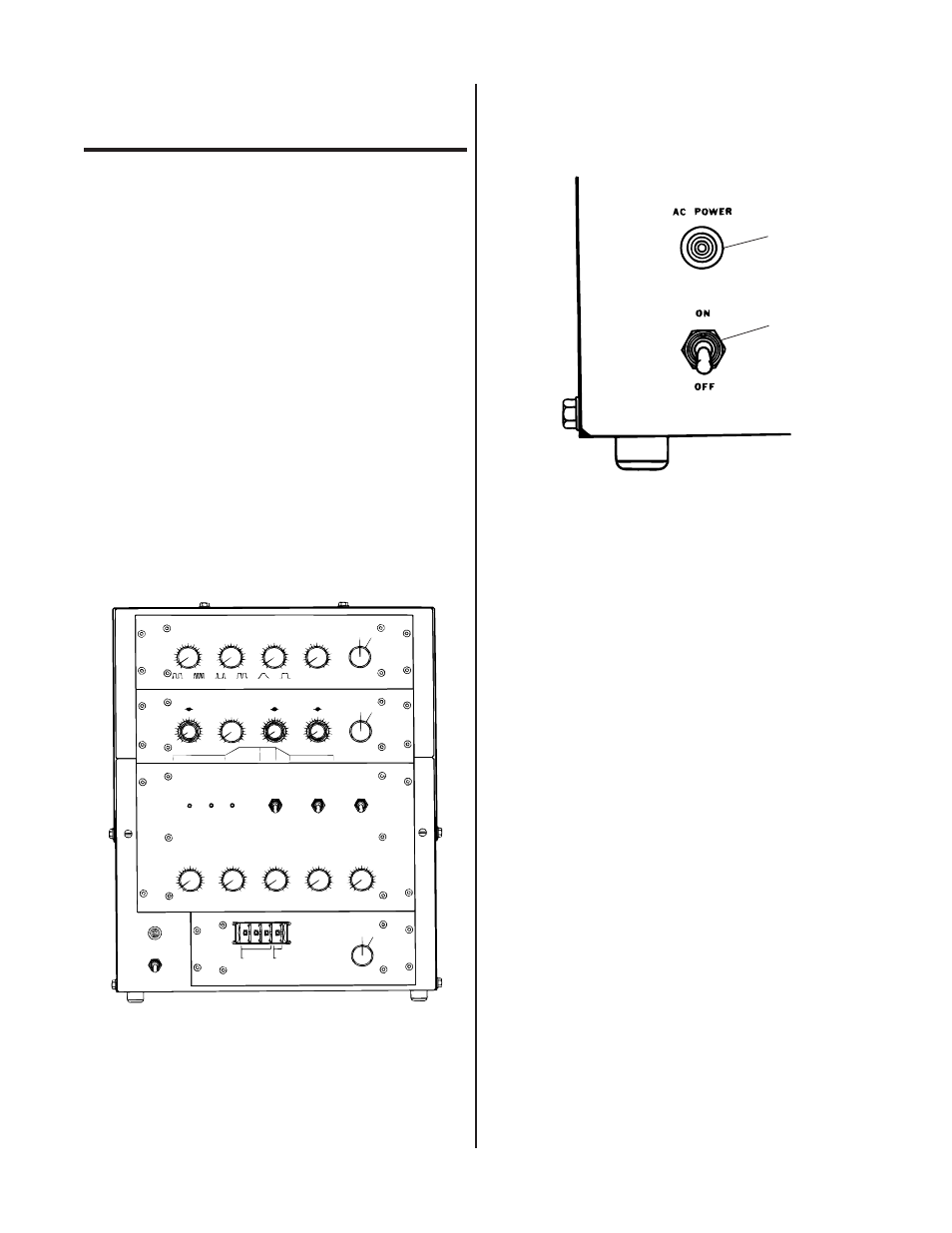

Page 25: 03 weld sequencer enclosure control descriptions, Section 4, Operation, Figure 4-2 weld sequencer enclosure, Wt 1

Manual 0-2023

19

OPERATION

SECTION 4:

OPERATION

4.01 Introduction

This section provides a description of the Power Supply

operating controls and procedures. Identification of the

Front and Rear Panel components is followed by operat-

ing procedures.

4.02 Functional Overview

The Weld Sequencer is designed to automatically control

the output of most solid-state power supplies. The Weld

Sequencer gives the operator more accurate control of the

variables within a welding operation. Once the Weld Se-

quencer is programmed for a particular welding opera-

tion, the weld can be reproduced with minimal fluctua-

tions. Four separate solid-state control modules, a Weld

Sequencer Enclosure and a RP1 Control remote pendant

make up the Weld Sequencer. Any combination of the

four modules can be used with the Weld Sequencer En-

closure to be a stand-alone unit.

CP1

PULSER

CS1

CURRENT SLOPE

GS1

GAS SLOPE

WT 1

WELD TIMER

T E N T H S

S E C O N D S

O N

O F F

O N

AC P OW E R

O F F

M I N

G A S F L OW

. 5 - 3 S C F H

. 2 5 - 1 . 4 l p m

M A X

G A S F L OW

2 - 7 S C F H

1 - 3 . 3 l p m

0

1

2

3

4

5

6

7

8

9

1 0

0

1

2

3

4

5

6

7

8

9

1 0

U P S L O P E

R AT E

0

1

2

3

4

5

6

7

8

9

1 0

D OW N S L O P E

R AT E

0

1

2

3

4

5

6

7

8

9

1 0

D OW N S L O P E

D E L AY

( 0 - 1 0 s e c . )

0

1

2

3

4

5

6

7

8

9

1 0

A - 0 2 4 1 4

O N

O F F

O N

O F F

I N I T I A L

0

1

2

3

4

5

6

7

8

9

1 0

C U R R E N T T I M E

0

1

2

3

4

5

6

7

8

9

1 0

U P S L O P E R AT E

D OW N S L O P E

0

1

2

3

4

5

6

7

8

9

1 0

D E L AY R AT E

F I N A L

0

1

2

3

4

5

6

7

8

9

1 0

C U R R E N T T I M E

0 - 10 sec.

0 - 10 sec.

weld time

0 - 10 sec.

G A S F L OW

M I N

S L O P I N G

M A X

U P

D OW N

M A N UA L

AU TO

O N

O F F

0

1

2

3

4

5

6

7

8

9

1 0

P U L S E R AT E

0

1

2

3

4

5

6

7

8

9

1 0

P E R C E N T O N T I M E

0

1

2

3

4

5

6

7

8

9

1 0

P U L S E S L O P E

0

1

2

3

4

5

6

7

8

9

1 0

BAC K G RO U N D C U R R E N T

( p u l l fo r d i s p l ay )

Figure 4-1 Control Modules Assembled In Weld

Sequencer Enclosure

4.03 Weld Sequencer Enclosure

Control Descriptions

A - 0 2 4 1 5

1

2

Figure 4-2 Weld Sequencer Enclosure

1. ON/OFF Switch

Activates Weld Sequencer Enclosure power circuits

and supplies AC power to all Sequencer Controls in

ON position. In the OFF position deactivates all Se-

quencer Control circuits.

2. Red AC Power Light

Indicates that AC power is being supplied to the Se-

quencer control modules.