10 system operation – Tweco Weld Sequencer User Manual

Page 33

Manual 0-2023

27

OPERATION

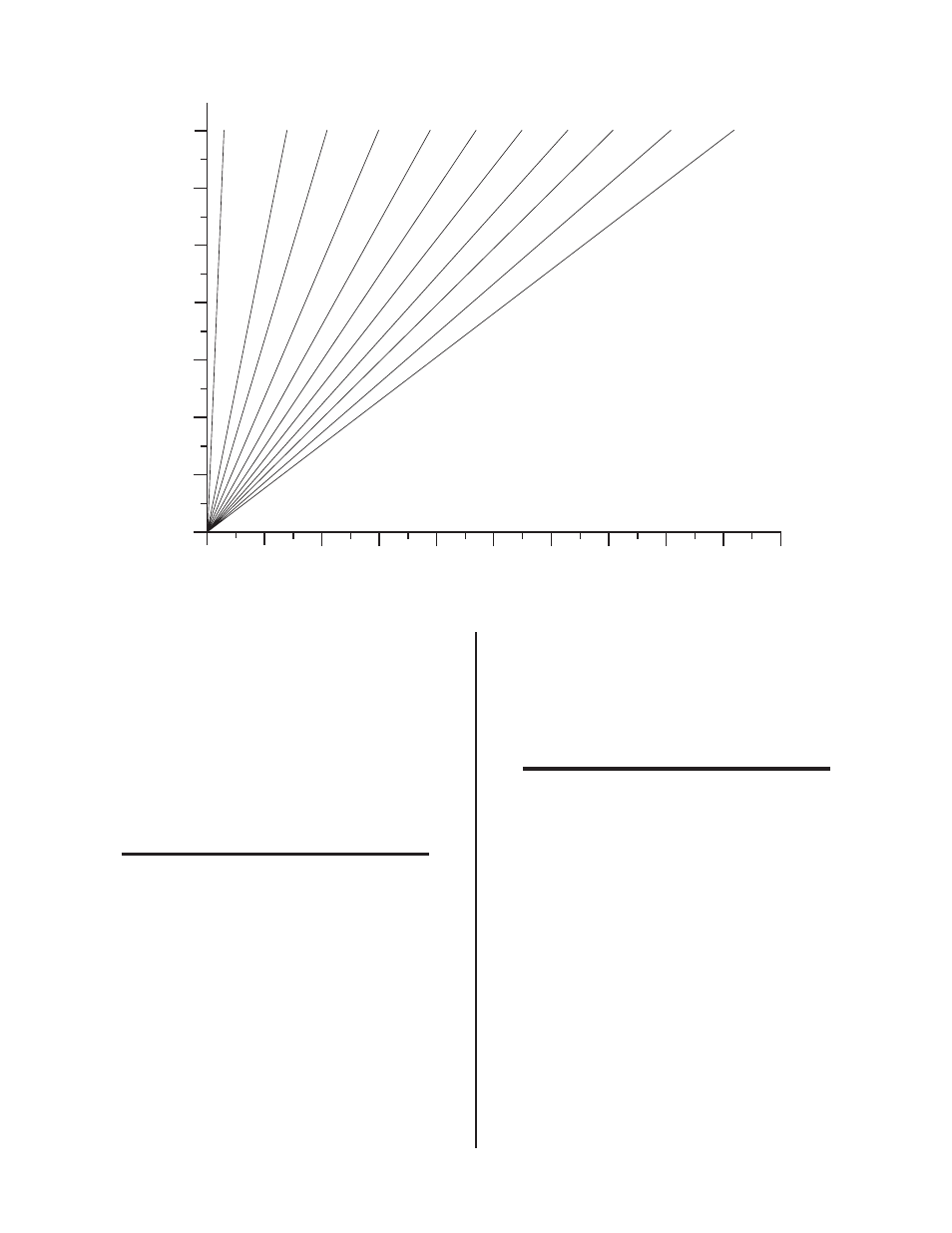

10. Adjust GS1 DOWNSLOPE RATE to correspond to

current downslope rate (if CS1 is used) or to achieve

the desired rate refer to Figure 4-10.

11. Adjust delay time for the start of downslope using

the GS1 DOWNSLOPE DELAY knob. The numbers

specify delay time in seconds (from 0 to 10 seconds).

4.10 System Operation

NOTES

Refer to Appendix VI for timing and detailed se-

quence of operation for all Weld Sequencer Mod-

els.

Refer to Appendix VII for timing and detailed se-

quence of operation for GS1 Gas Slope Only.

1. Position torch for start of weld.

2. Turn on gas supplies.

3. Activate welding console, coolant recirculator, power

supply, weld sequencer and any accessory control cir-

cuits.

4. Turn on all control modules in the weld sequencer that

are to be used.

5. Move the RP1 Control CONTACTOR ON/OFF switch

to ON position to close the main contactor.

6. Push the RP1 Control START SEQUENCE switch to

start the welding sequence (see NOTES).

NOTES

1. If spot welding, once the CONTACTOR switch

is moved to ON position only the SPOTWELD

switch must be pressed to continue.

2. If GS1 is not used the entire weld sequence will

start with contactor closure and pressing the

START SEQUENCE switch. If GS1 is set in to

MANUAL, CS1 (if used) will not operate.

3. If CS1 is not used and GS1 is set to MANUAL,

start gas upslope by pressing the RP1 Control

START SEQUENCE switch. Start gas

downslope by pressing the RP1 Control START

DOWNSLOPE switch.

0

0

1 0

2 0

3 0

4 0

5 0

6 0

7 0

8 0

9 0

1 0 0

1

2

3

4

5

6

7

A - 0 2 4 3 6

Rate = 10

Rate = 9

Rate = 8

Rate = 7

Rate = 6 Rate = 5 Rate = 4 Rate = 3Rate = 2 Rate = 1

Rate = 0

T i m e ( S e c o n d s )

Max - Min Gas Flo

w (scfh)

Figure 4-10 GS1 Upslope and Downslope Rate Selection