05 wt1 weld timer – Tweco Weld Sequencer User Manual

Page 19

Manual 0-2023

13

INSTALLATION PROCEDURES

2. Connect the mating plug of the 10 foot (3 m) Control

Cable to the receptacle on the rear panel of the Weld

Sequencer Enclosure marked CONSOLE/POWER

SUPPLY CONTROL.

3. The connection on the other end of the cable depends

on the welding console, power supply or current con-

trol device. Connect as follows (refer to Figure 3-4):

• Thermal Arc WC100B Welding Console

a. Connect Control Cable plug to the receptacle on

the front panel of the WC100B marked REMOTE

CONTROL. Move REMOTE ON/OFF switch to

ON position.

• Thermal Arc WC100A and WC122A (and earlier

models) Welding Consoles

b. Cut the Control Cable plug off and strip cable jacket

back approximately 2 inches.

c. Locate the cable from the welding console CON-

TROL receptacle. Measure enough cable to con-

nect with the Control Cable from the Weld Se-

quencer Enclosure and cut.

d. Connect the white/brown (J5-3) and black (J5-4)

wires of the Weld Sequencer Enclosure Control

Cable to the two leads of the cable from the weld-

ing console CONTROL. The order of connection

is unimportant. This connection gives contactor

control to the Sequencer.

e. Connect a cable to the Remote Amperage Control

of the power supply. Connect the other end to the

Weld Sequencer Enclosure Control Cable (see Fig-

ure 3-E):

Power Supply Amperage Control maximum lead

to orange wire (J5-1)

Power Supply Amperage Control variable (wiper)

lead to red wire (J5-7)

Power Supply Amperage Control minimum lead

to blue wire (J5-13)

C o n t a c t o r

C o n t r o l

A M P C o n t r o l

( W i p e r )

A M P C o n t r o l

( M i n )

A M P C o n t r o l

( M a x )

C o n t a c t o r

C o n t r o l

G r o u n d

1

4

8

1 3

7

3

A - 0 2 4 0 8

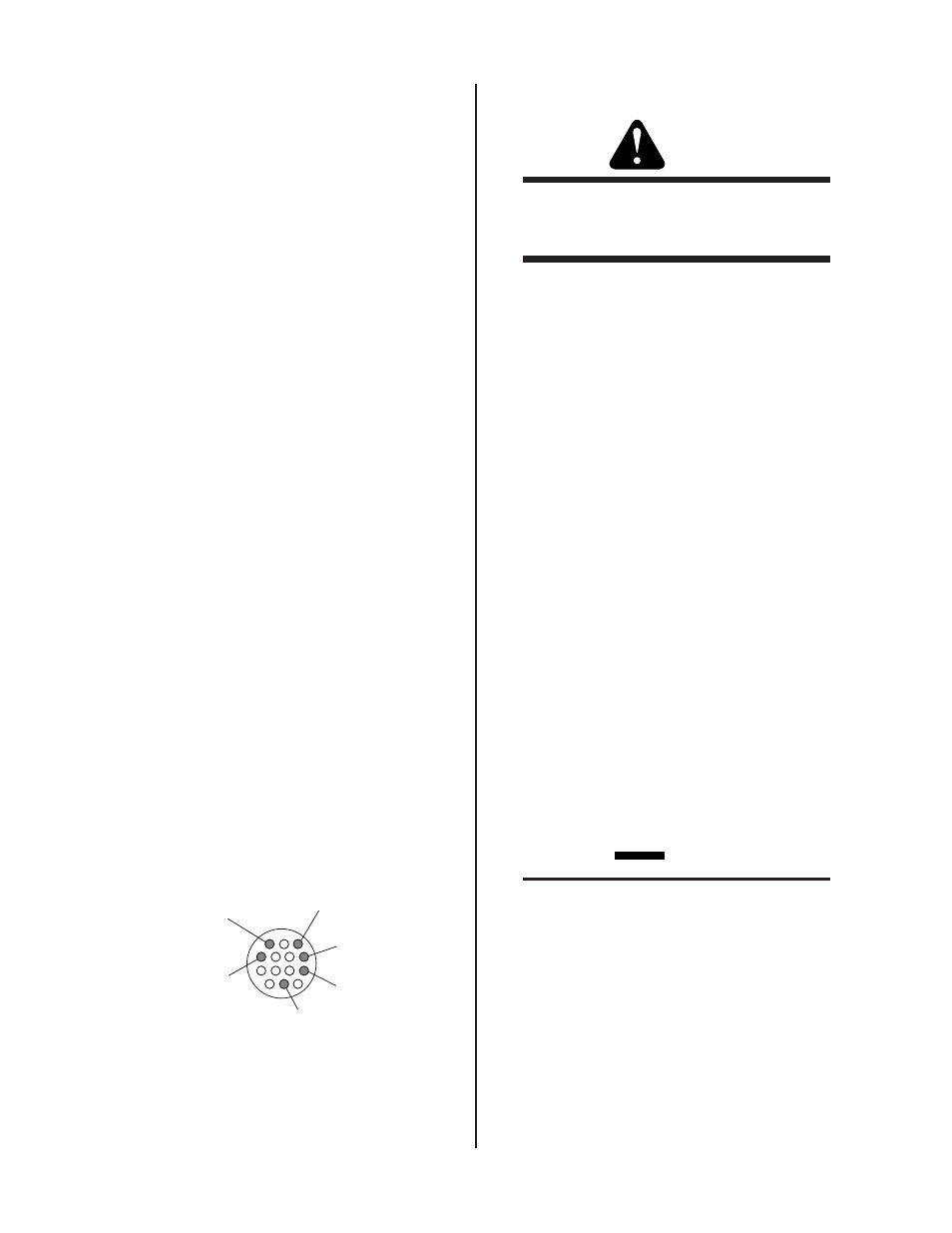

Figure 3-5 Back View of Control Cable Plug

f. Tape back the wires not used.

• Other Welding Consoles and Power Supplies

WARNING

The remote control circuit of the welding console

or power supply must not exceed 28 volts AC or

DC.

a. Cut the cable plug off. Strip the cable jacket back

approximately 2 inches.

b. Connect the white/brown (J5-3) and black (J5-4)

wires of the Weld Sequencer Enclosure Control

Cable to the contactor control of the welding unit.

This gives contactor control to the Sequencer.

c. Connect a cable to the Remote Amperage Control

of the power supply. Connect the other end to the

Weld Sequencer Enclosure Control Cable (refer to

Figure 3-5):

Power Supply Amperage Control maximum lead

to orange wire (J5-1)

Power Supply Amperage Control variable (wiper)

lead to red wire (J5-7)

Power Supply Amperage Control minimum lead

to blue wire (J5-13)

d. Tape back the wires not used.

e. Check input power connections on the terminal

strip TB4, located on the rear panel of the Weld

Sequencer Enclosure, to be sure that they are set

up for the available voltage. Provisions are made

for primary inputs of 115 or 230 volts AC (refer to

Section 4.2) and 50 or 60 Hz power may be used.

3.05 WT1 Weld Timer

CAUTION

The WT1 Weld Timer is factory set for 60 Hz op-

eration. If 50 Hz power is used or WT1 doesn’t

time properly remove the cover from WT1 and check

the position of the switch mounted in the middle of

the PC board. Move the handle to the proper posi-

tion printed on the PC board (50 or 60).

1. Install WT1 into the bottom of the opening in the Weld

Sequencer Enclosure (refer to Figure 3-6). Secure with

screws provided.

2. Connect WT1 to the Weld Sequencer Enclosure wiring

harness with the J4 connectors.