Section 2: introduction & description, 01 scope of manual, 02 general description – Tweco Weld Sequencer User Manual

Page 15: Section 2, Introduction & description, 01 scope of manual 2.02 general description

Manual 0-2023

9

INTRODUCTION & DESCRIPTION

SECTION 2:

INTRODUCTION &

DESCRIPTION

2.01 Scope of Manual

This manual contains descriptions, operating instructions

and maintenance procedures for the Thermal Arc Weld

Sequencer. Service of this equipment is restricted to prop-

erly trained personnel; unqualified personnel are strictly

cautioned against attempting repairs or adjustments not

covered in this manual, at the risk of voiding the War-

ranty.

Read this manual thoroughly. A complete understand-

ing of the characteristics and capabilities of this equip-

ment will assure the dependable operation for which it

was designed.

2.02 General Description

The Thermal Arc Weld Sequencer is an accessory pack-

age designed to automatically control the output of most

solid-state power supplies. The Weld Sequencer gives the

operator more accurate control of the variables within a

welding operation. Once the Weld Sequencer is pro-

grammed for a particular welding operation, the weld

can be reproduced with minimal fluctuations. Four sepa-

rate solid-state control modules, a Weld Sequencer En-

closure and a RP1 Control remote pendant make up the

Weld Sequencer. Any combination of the four modules

can be used with the Weld Sequencer Enclosure to be a

stand-alone unit.

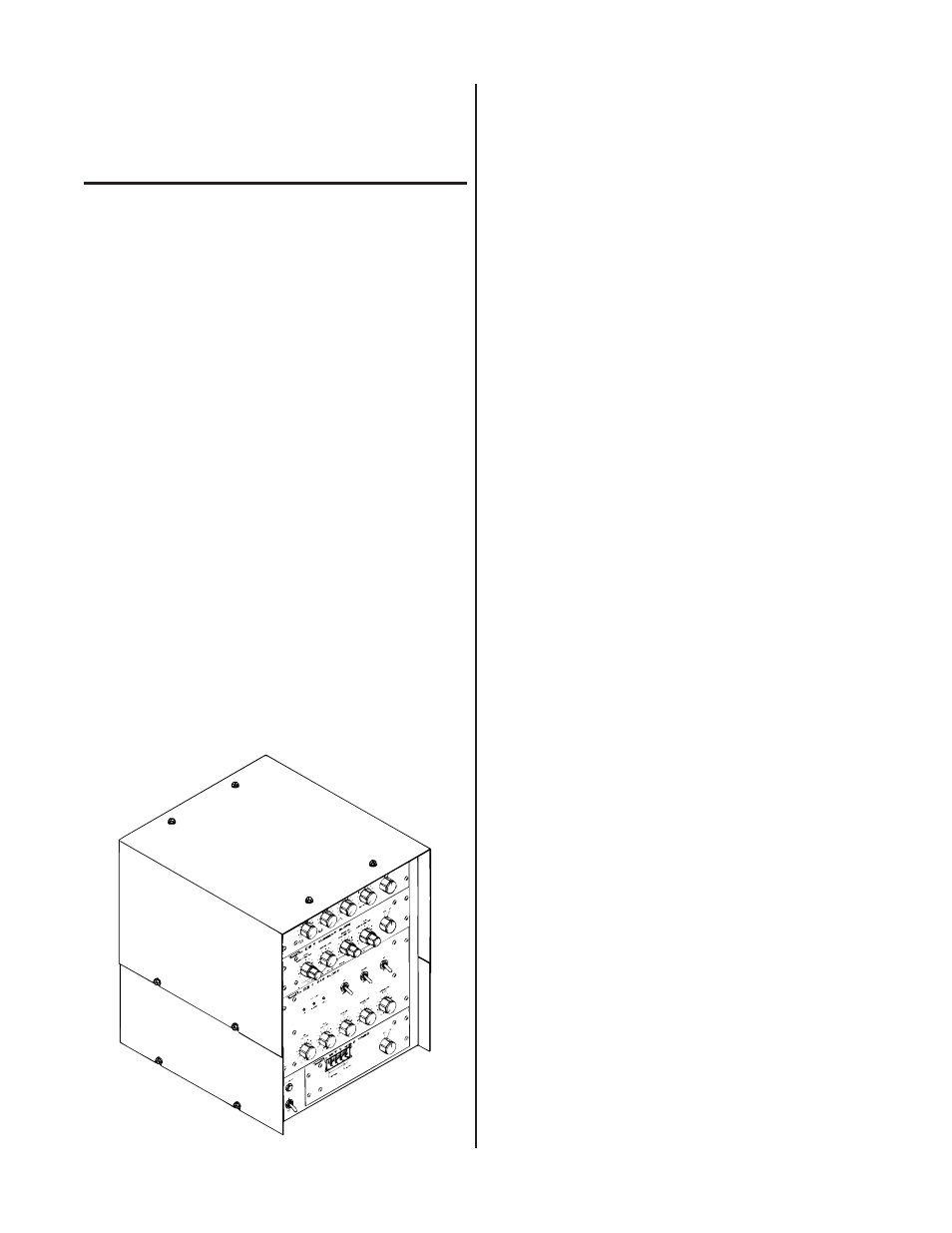

A-02401

Figure 2-1 Weld Sequencer Assembly

• Weld Sequencer Enclosure

Housing for combinations of the four modules.

Contains interface wiring and power for each unit.

Provides relay contacts for interfacing with exter-

nal controls (wire feeders, motion controls, etc).

• RP1 Control

Offers remote control for activating main contac-

tor, starting weld sequencer, starting downslope

manually, starting spot weld sequence, and adjust-

ing welding current.

• CS1 Current Slope

Allows welding current to be automatically ad-

justed from an initial current setting to a peak cur-

rent setting (upslope) and decreased automatically

to a final current setting (downslope) when sig-

naled manually or by the WT1 Weld Timer.

Upslope changes the current linearly from initial

current value to weld (peal) current value.

Downslope changes the current linearly from peak

value down to final value.

• GS1 Gas Slope (Plasma Gas)

Allows linear change in the plasma gas flow rate

(upslope and downslope) between two variable

settings. The control can be manual or automatic

when used with CS1 Current Slope

• CP1 Pulser

Reduces the amount of heat input into the weld

by pulsing the current between peak level and a

background level. The CP1 offers complete con-

trol of the pulse frequency rate and the percent-

age of 'on' time at peak current versus background

current. The CP1 also offers the capability of a lin-

ear upslope and downslope on each pulse.

• WT1 Weld Timer

Allows weld time to be set from 0.1 to 999.9 sec-

onds. When used with CS1 Current Slope the WT1

times the weld from the start of upslope to the end

of peak (weld) current at which time it provides a

signal for initiating the downslope sequence. WT1

can also be used independently as a spot weld

timer.