24v rgbw led tape light, Rgbw clicktight, Connectors troubleshooting – Diode LED RGBW LED Tape Light User Manual

Page 3

1.877.817.6028

www.DiodeLED.com

www.DiodeLED.com

INSTALLATION GUIDE

3 OF 4

DAZZLE 24

™

24V RGBW LED TAPE LIGHT

®

+

−

+

−

+

−

+

−

+

−

+

−

Prior to troubleshooting, ensure all items are a compatible system and main power is turned ON.

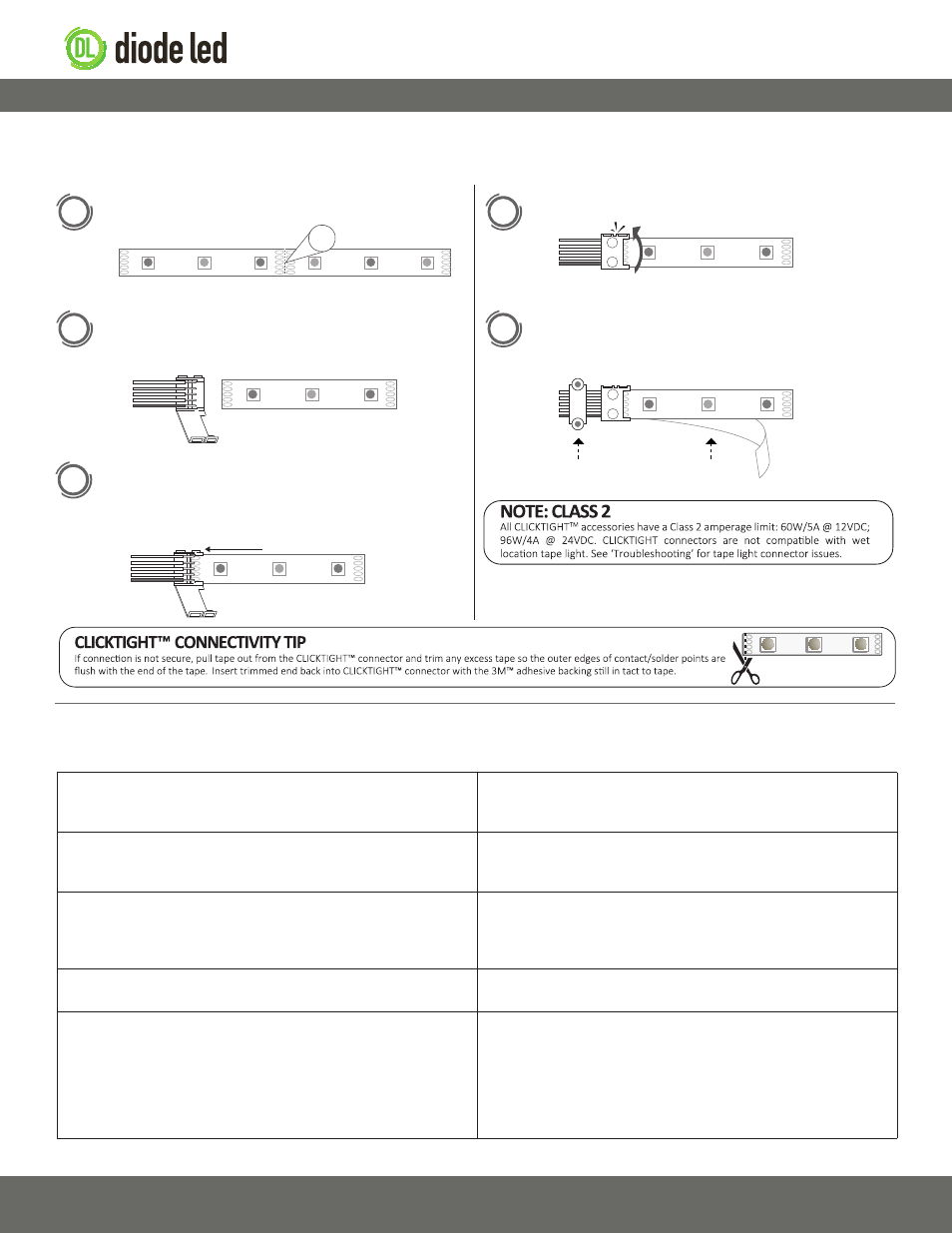

RGBW CLICKTIGHT

™

Connectors

Troubleshooting

1

IG082514-1.3

2

Cut the tape at the line indicated with the scissors icon.

Close the CLICKTIGHT™ latch to ensure connection.

When ready for mounting, peel off the 3M™ adhesive backing

of the tape and tear off along the connector tray edge. Mount

tape light and utilize a wiring harness to secure lead wires.

Open the CLICKTIGHT™ latch and note the +/- polarity markings.

Firmly insert the tape light into the connector tray with the

3M™ adhesive backing still intact to the tape. Ensure the

contact/solder points of the tape are directly underneath the

metal placement tabs of the connector.

3

4

5

These instructions apply only to RGBW CLICKTIGHT™ Connectors (does not apply to solid color CLICKTIGHT™ Connectors). Never cut tape attached to

a live circuit.

W

V+

G

R

B

+

−

+

−

Shift in brightness and/or kelvin

• Review maximum series run limits. Exceeding these limits will cause

excess voltage drop, decreasing brightness and/or kelvin as the run is

extended.

Some LEDs are not functional

• Ensure all connections have been properly attached. Ensure fixture

has not been bent excessively, which may cause components and sol-

der to detach from the circuit board.

Lights are flickering

• Ensure a compatible driver is installed. Ensure the pre-set mode of the

controller is not on a dynamic mode. Ensure Data +/- connections of

DMX systems are not reversed. If lights continue to flicker, check for

loose connections. Ensure tape light connectors are properly attached.

Lights are turning on/off repeatedly

• Ensure driver is not overloaded. An overloaded driver will trip the in-

ternal auto-reset (of driver) repeatedly, turning the system on/off.

CLICKTIGHT™ Connector Troubleshooting

• Ensure compatible CLICKTIGHT™ models are attached. Tape lights vary

in width and require specific connectors. Contact your supplier for

additional information.

• Tape light is polarity sensitive. Ensure the +/- markings of the CLICKTIGHT™

connector is aligned with the +/- markings of the tape. If polarity is

backwards, reverse the lead wire connection or detach tape from

CLICKTIGHT™ connector and reattach opposing end of tape to connector.

Cut points not drawn to scale.

Wiring Harness

3M™ Adhesive