6 wiring start / stop control – Rockwell Automation VSM500 Integrated Drive/Motor User Manual

Page 42

7-12

Installing and Operating the VSM500 Integrated Drive/Motor, Version 3.0

7.6

Wiring Start / Stop Control

Important: This applies only to standard units and local operator control units set up

for terminal block control (setup slide switch position 9 = ON, see section

8.3.9).

The system looks for an open-to-closed transition at the Start input before starting the

unit unless you have the Power-Up Start switch (setup slide switch 1, see section

8.3.1) set to ON. If you use a maintained start device and power to the unit is lost, you

must open and reclose the start device before the unit will start again. Both the Stop

and the Function Loss input signals must be present and there must be no active

faults for the unit to start.

In order for the unit to run, you must maintain a signal at the Stop input. If the signal is

interrupted, the unit coasts to rest (default) or ramps to rest (user option). To restart

the unit, you must restore the signal and reassert the Start input.

The unit ships from the factory with a jumper on the Stop input terminals (terminals 13

and 17) which permits the unit to be started. To stop the unit using the terminal block

inputs, you must remove the factory jumper and install appropriate stop wiring.

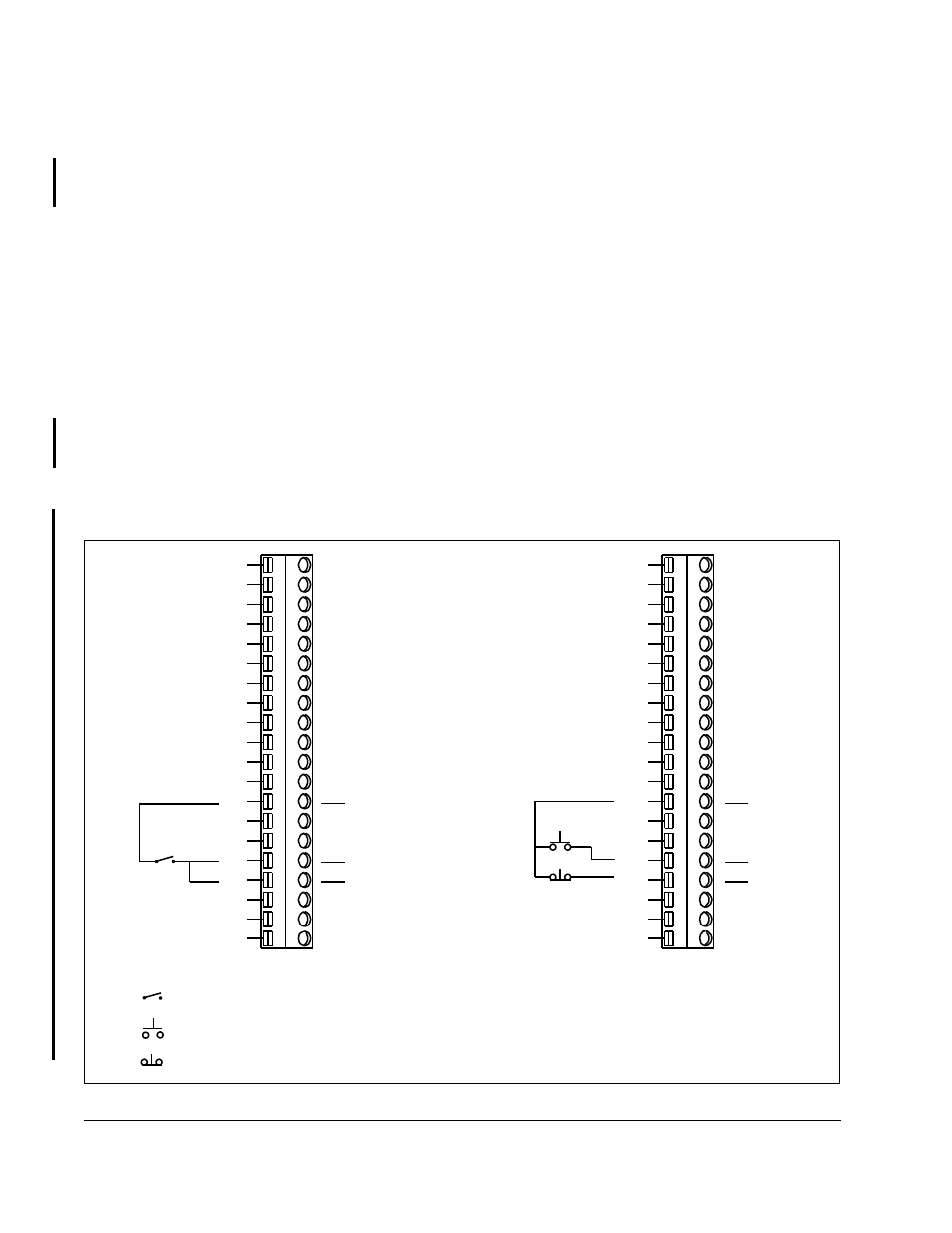

Figure 7.12 illustrates wiring for a maintained 2-wire and for a momentary 3-wire

Start / Stop control.

Figure 7.12 – Start / Stop Control Wiring

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Stop

Start

24V DC

18

19

12

15

17

16

14

13

9

10

11

7

8

6

4

5

3

1

2

N.O

N.C.

Maintained 2-Wire

Momentary 3-Wire

= Maintained Contact - Open

= N.O. Momentary Contact

= N.C. Momentary Contact

24V DC

Start

Stop

20

20

Important: To stop the unit using the

terminal block inputs, the jumper between

terminals 13 and 17 must be removed when

wiring the Stop input.