Hapter, Step 7 - wire the control signal terminal block – Rockwell Automation VSM500 Integrated Drive/Motor User Manual

Page 31

Step 7 - Wire the Control Signal Terminal Block

7-1

C

HAPTER

7

Step 7 - Wire the Control Signal

Terminal Block

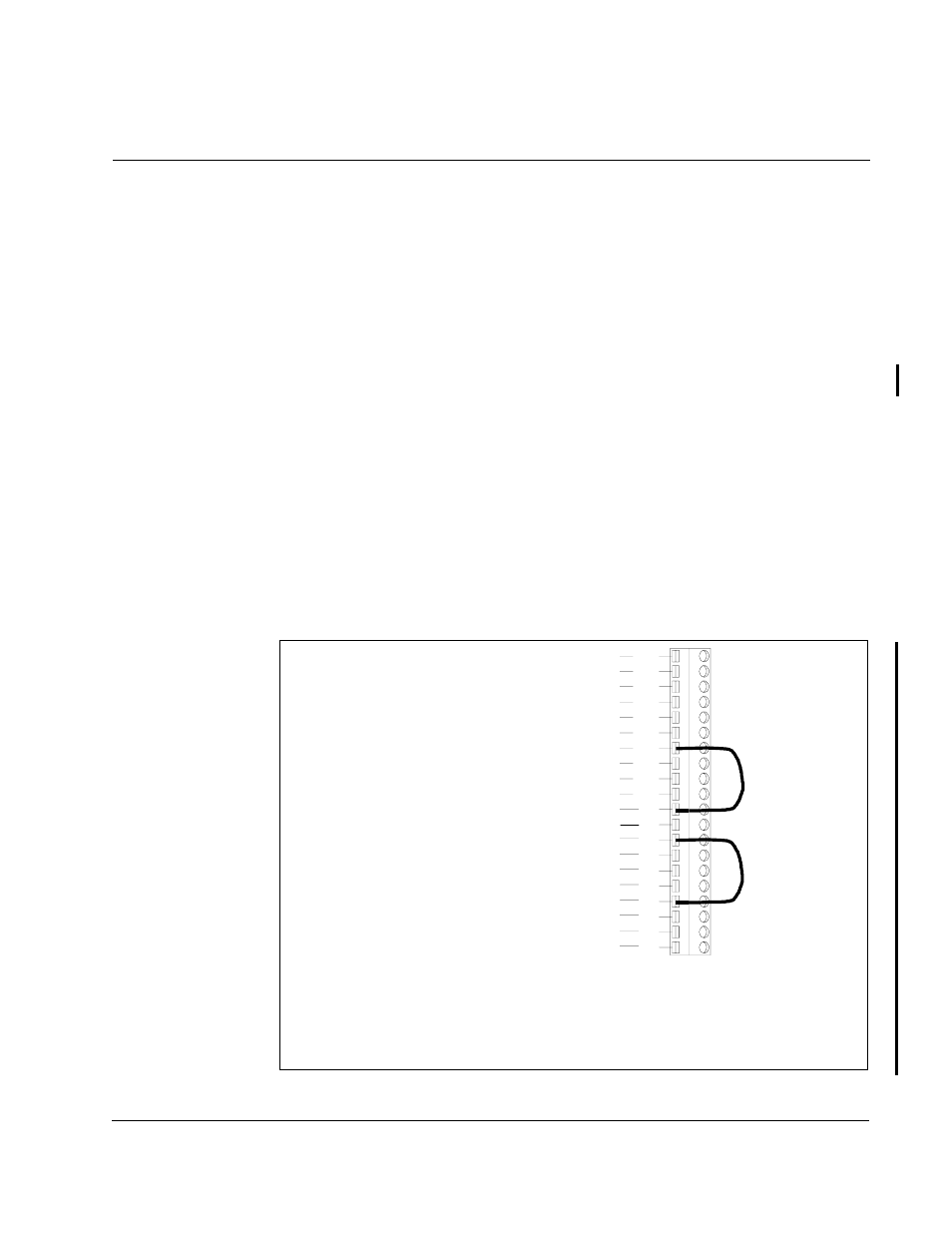

The following sections describe how to wire the control signal terminal block shown in

figure 7.1.

Refer to either figure 7.2 (standard units or local operator control units set up for

terminal block control) or figure 7.3 (local operator control units) before you begin

wiring. These figures show typical wiring connections and the sections in this chapter

where the signals are described in detail.

Note the following when wiring the terminal block:

•

The terminal block is isolated from the input power.

•

Route the control wires separately from the power wires.

•

The terminal block accepts 0.326 mm

2

(22 AWG) through 3.31 mm

2

(12 AWG) wire.

•

The maximum lead length is 300 meters (1000 ft

).

•

The maximum tightening torque is 0.8 Nm (7 in-lb).

Figure 7.1 – Control Signal Terminal Block

Control Signal Terminal Block

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Relay Common

N.O. Relay

24V DC Common

Stop

Start

Reset

Forward/Reverse

24V DC

Function Loss

Speed Preset 0

Speed Preset 1

Speed Preset 2

24V DC

Common

0 to 10V Output

Common

4 to 20mA Speed Reference Input

0 to 10V Speed Reference Input

10 Volt Reference

RPM / %Load Display

20

1>

2>

1> The jumper between terminals 7

and 11 must be removed when

wiring the Function Loss input. See

section 7.1 for more information.

2> Important: To stop the unit using the

terminal block inputs, the jumper

between terminals 13 and 17 must be

removed when wiring the Stop input.

See section 7.6 for more information.