2 control and signal wire sizes, 3 recommended motor lead lengths – Rockwell Automation SP600 User Manual Version 3.0 User Manual

Page 53

Wiring Requirements for the Drive

4-5

4.2

Control and Signal Wire Sizes

The terminal block on the SP 600 I/O interface board provides

terminals for 24 V or 115 VAC power for the control inputs,

depending on the I/O card installed in the drive. Refer to 4.3 for

signal and control wiring specifications.

4.3

Recommended Motor Lead Lengths

Important:

To reduce line disturbances and noise, motor lead

length should not exceed 300 feet for any non-

Reliance Electric motor or any non-inverter duty

motor.

The length of cable between the drive and motor may be limited for

various applications reasons. The primary reasons are:

•

Reflected wave

•

Cable charging

!

ATTENTION: Verify the voltage rating of the I/O interface

board before wiring any user devices. Failure to observe this

precaution could result in damage to, or destruction of, the

equipment.

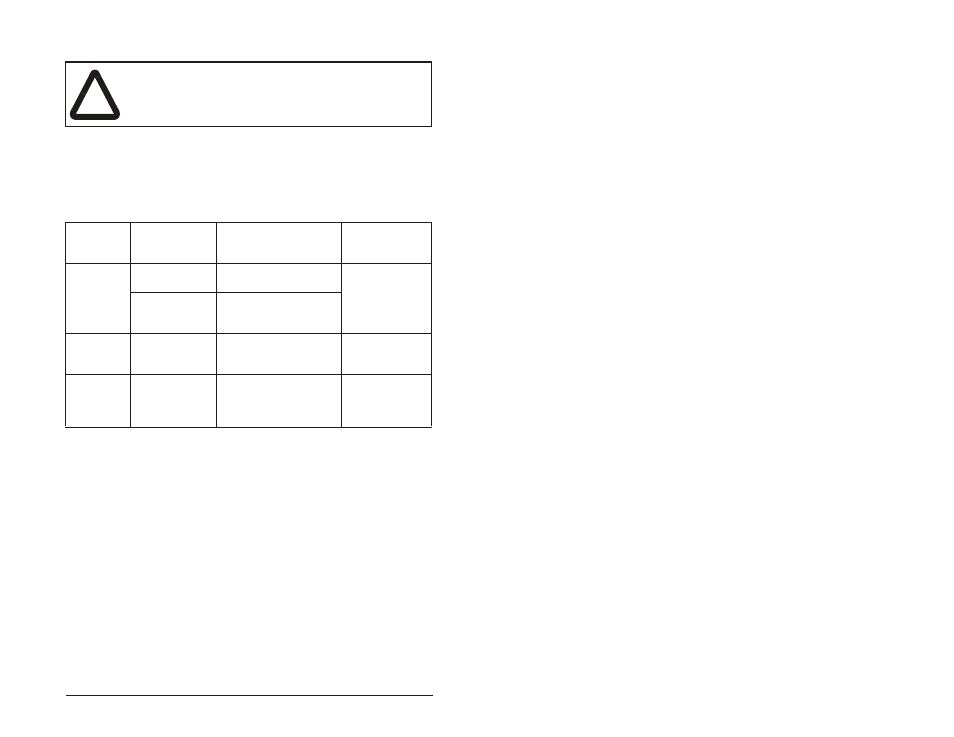

Table 4.3 – Recommended Signal and Control Wire

Signal

Type

Wire Type(s)

Description

Minimum

Insulation

Rating

Analog I/O

Belden 8760/

9460 (or equiv.)

18AWG, twisted pair,

100% shield with drain

1

.

300V, 60

°

C

(140

°

F)

Belden 8770

(or equiv.)

18AWG,

3-conductor, shielded for

remote pot only.

Unshielded

Control

Per US NEC or

applicable local

code

300V, 60

°

C

(140

°

F)

Shielded

Control

Multi-conductor

cable such as

Belden 8770

(or equiv.)

18 AWG, 3-conductor

shielded.

300V, 60

°

C

(140

°

F)

1

If the wires are short and contained within a cabinet which has no sensitive circuits,

the use of shielded wire may not be necessary, but is always recommended.