When is a tachometer required – Rockwell Automation 7000A PowerFlex Medium Voltage AC Drive - Air-Cooled (A Frame) User Manual

Page 380

A-4

Catalog Number Explanation – Drive Selection

7000A-RM001A-EN-P – January 2011

7000 “A” Frame

A tachometer is required under the following conditions:

1. When speed regulation accuracy must be between 0.01 – 0.02%

of nominal speed.

2. When the zero speed breakaway torque needed is greater than

90% of continuous running torque.

3. When continuous running speed is greater than or equal to 0.1

Hz, but less than 6 Hz.

4. For minimizing restart times using the flying start capability in

forward or reverse direction.

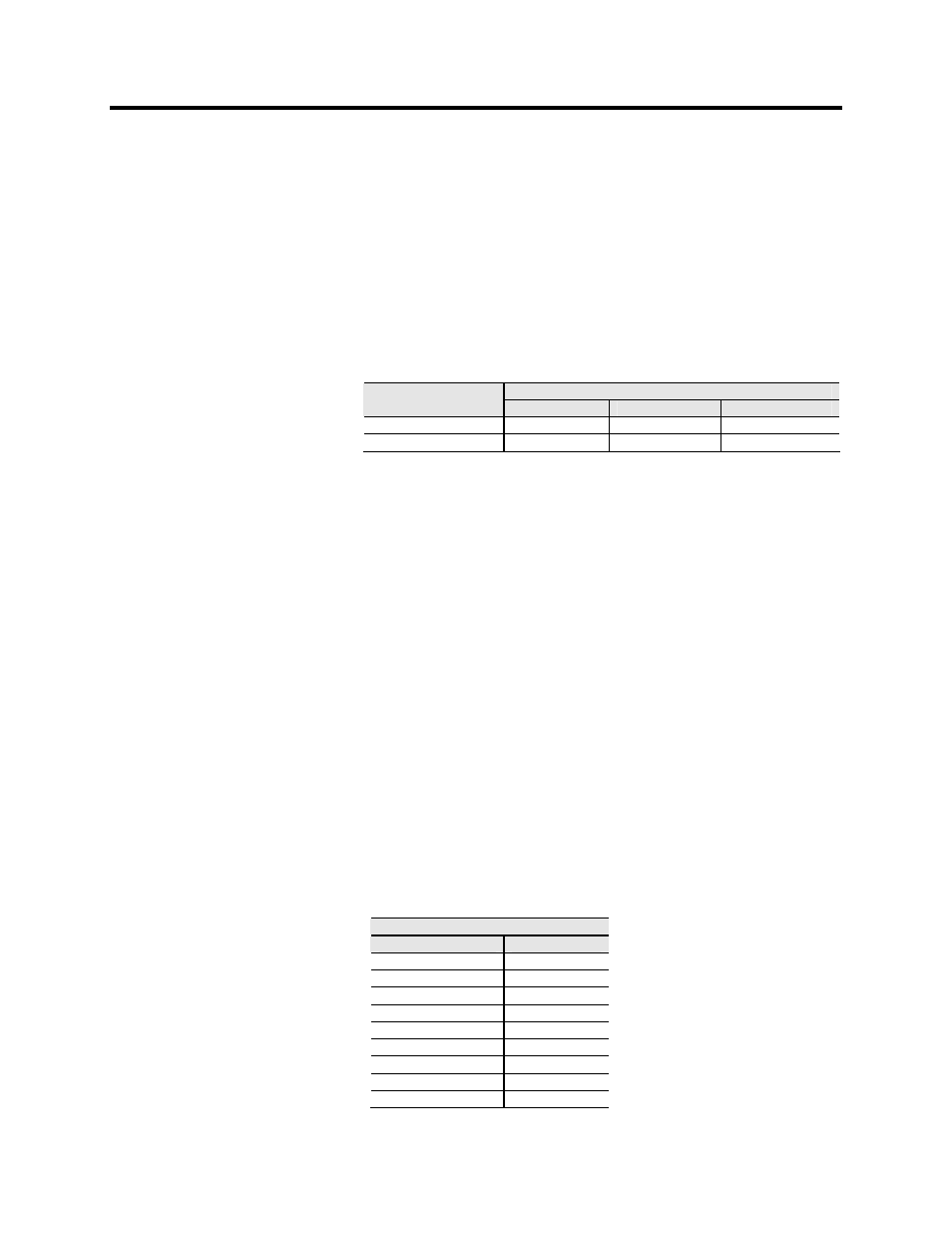

Table A-2 –Power Flex Speed Regulation

Frequency Output

Tachometer

< 6 Hertz

6 – 15 Hertz

Above 15 Hertz

Without Tachometer

Not applicable

0.1 %

0.1 %

With Tachometer

0.02 %

0.01%

0.01%

Notes:

Speed Regulation is based on % of motor synchronous speed.

Tachometer to be mounted on the AC machine

Operational 15 V DC Power Supply mounted in drive to power

the tachometer as a standard option with the tachometer feed

back card.

Customer is responsible for providing and mounting of

tachometer

Sleeve bearing motors require the tachometer to have an axial

movement tolerance.

Recommended tachometers are the shaft mounting type,

examples are the Avtron 585 and 685 models or the Northstar

(Lakeshore) RIM Tach HS85, 12 to 15V models or equivalent.

Magneto resistive models are more adaptable to harsh

environments.

When installing, the tachometer body and electronics must be

isolated from ground (options available from the tachometer

manufacturer to accomplish this).

When cable lengths exceed 305 m (1000 ft.) for the Northstar or

610 m (2000 ft.) for the Avtron, consult the factory.

Table A-3 – Tachometer Selection

Recommended Tach PPR

Motor RPM

Tach ppr

3600 600

3000 600

1800 1024

1500 1024

1200 2048

1000 2048

900 2048

720 2048

600 2048

When is a tachometer

required?

When is a tachometer

required?