Tachometer feedback board, Encoder options – Rockwell Automation 7000A PowerFlex Medium Voltage AC Drive - Air-Cooled (A Frame) User Manual

Page 330

5-88

Component Definition and Maintenance

7000A-RM001A-EN-P – January 2011

7000 “A” Frame

Tachometer Feedback Board

Encoder

Options

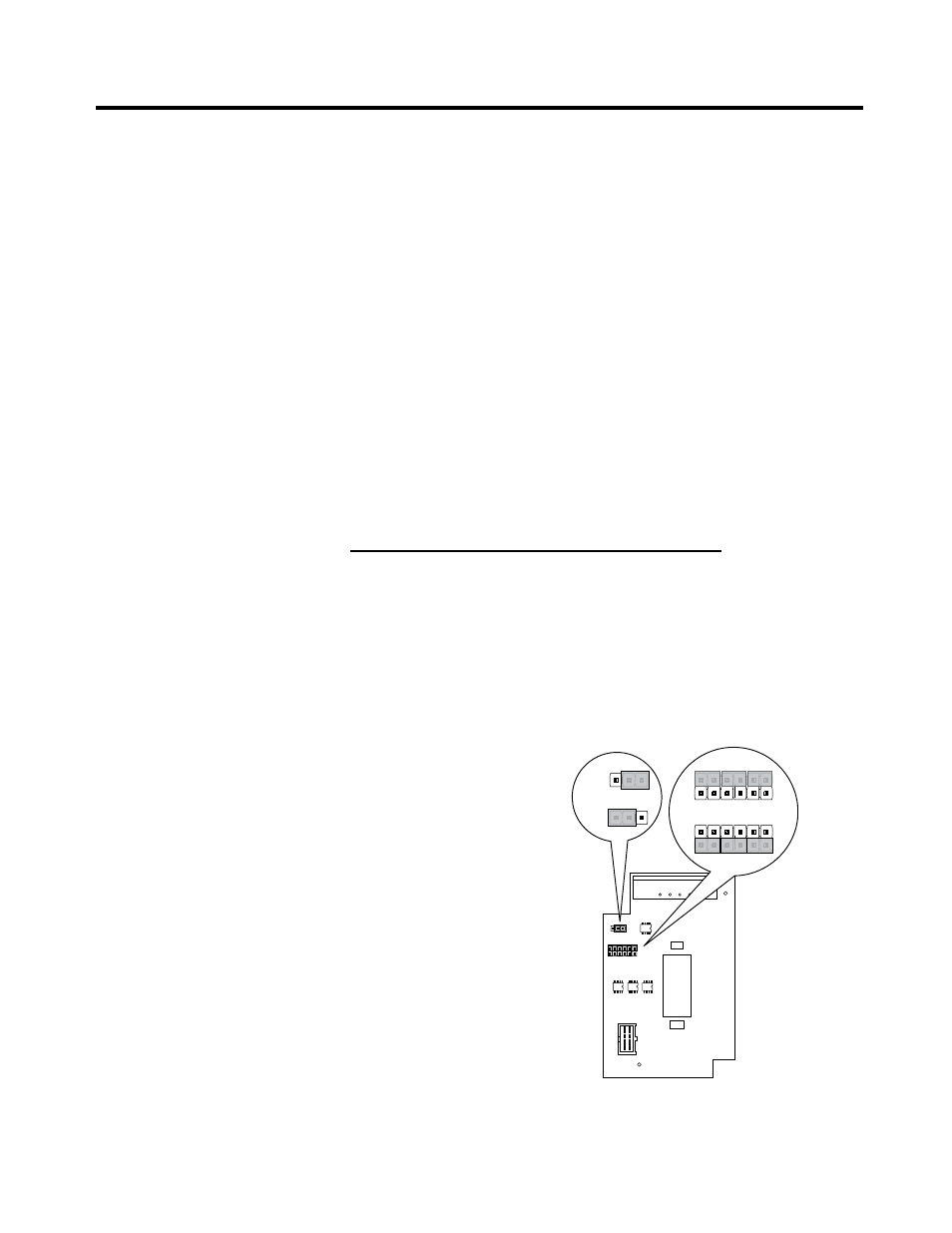

There are two positional encoder interface boards that may be used with the

PowerFlex 7000 Forge Control. The encoder interface boards do not have

any user accessible test points; however, buffered and isolated versions of

each of the signals A+, A-, B+, B-, Z+ and Z- are available on the ACB at

test points TP45-TP50.

Regardless of which type of encoder board, the following conditions

should be adhered to:

1.

Do not attach encoders with open collector outputs to the drive.

Acceptable outputs are Analog Line Driver or Push Pull.

2.

The drive will not operate properly if using single ended Quadrature

encoders. Rockwell Automation recommends using differential inputs

only for these types of encoders. Single ended outputs are only

acceptable for Positional Encoders.

20B-ENC-1 & 20B-ENC-1-MX3 Encoder Interface

This encoder interface allows the drive to be connected to a standard

Quadrature Encoder. The 20B-ENC encoder interface provides 3 optically

isolated differential encoder inputs for A and B phases as well as a Z

track. These inputs cannot be configured for use with a single ended

Encoder. Differential encoders only are supported. The board also

provides a galvanically isolated 12V/3Watt supply to power the attached

encoder. The 20B-ENC-1 Encoder interface may be configured for +5V

operation, however Rockwell recommends operation at 12V.

J3

J3

J2

+1

2V

1

2

3

12

11

21

+5VR

EF

1

2

3

+5V

+12V

1

2

3

+12V

+5V

12

11

21

12

11

21

Output

Config.

J2

Intput

Config.

Note: Must be configured

for 12V operation.

Figure 5.67 – Encoder Interface (20B-ENC-1 and 20B-ENC-1-MX3)