Rockwell Automation 1771-PD PID MODULE (+DU) User Manual

Page 61

Programming

Chapter 3

3Ć18

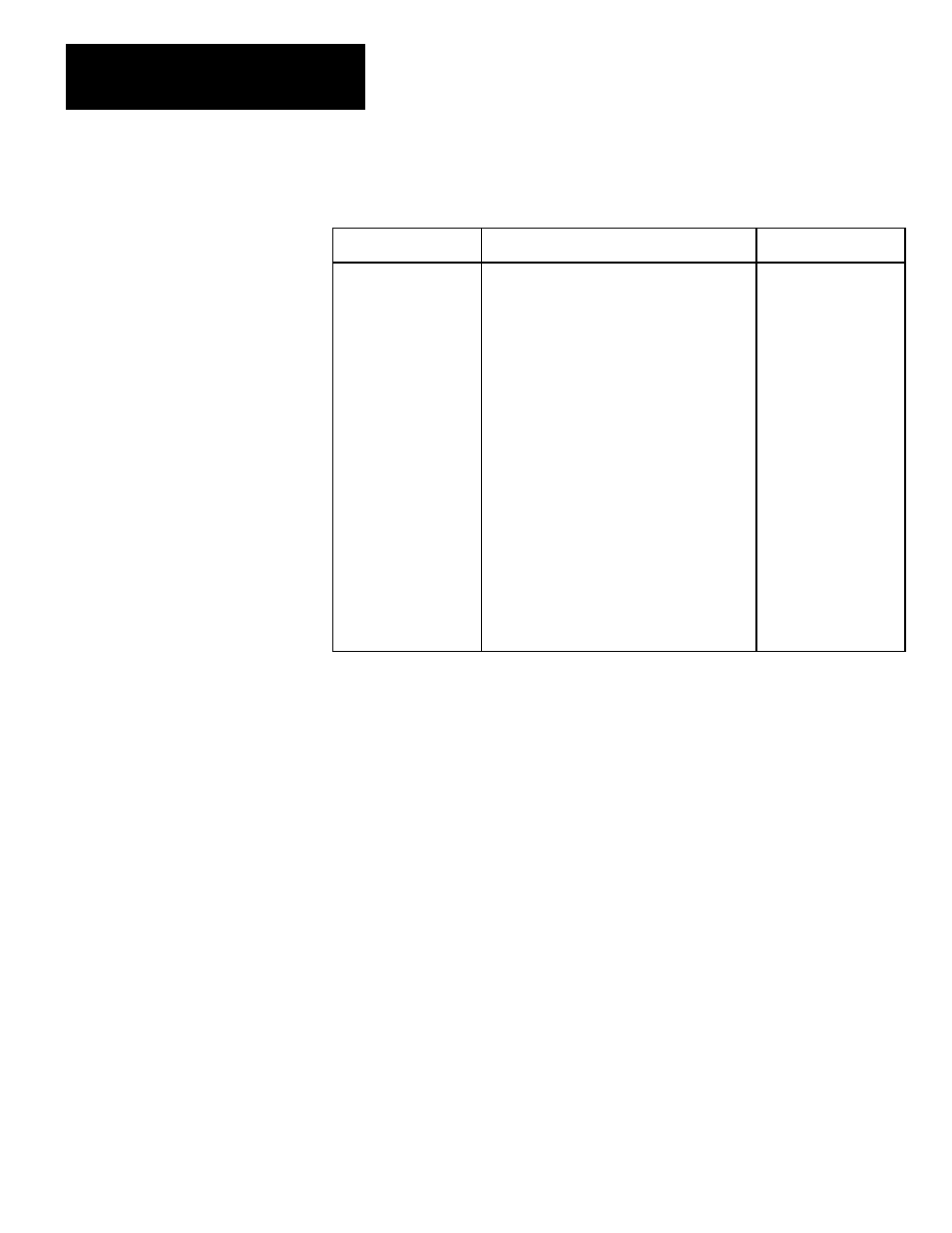

Table 3.C

Loop Block Words

Word

Title

Abbreviation

Standard Features

W18(W38)

W19 (W39)

W20 (W40)

W21 (W41)

W22 (W42)

W23 (W43)

W24 (W44)

W25 (W45)

W26 (W46)

W27 (W47)

W28 (W48)

W29 (W49)

Loop Control Word A

Loop Control Word B

Input Filter Time Constant

Maximum Negative Error

Maximum Positive Error

Dead Band

Integral Gain

Derivative Gain

Integral Term Limit

Derivative Term Limit

Minimum Output Limit

Maximum Output Limit

TA

EMN

EMP

DB

K

I

K

D

V

I

MAX

V

D

MAX

VMIN

VMAX

Expanded Features

W30 (W50)

W31 (W51)

W32 (W52)

W33 (W53)

W34 (W54)

W35 (W55)

W36 (W56)

Expanded Control Word

Minimum Scaling Value

Maximum Scaling Value

Feedforward Offset

Feedforward Gain

Lead Time Constant

Lag Time Constant

SMIN

SMAX

FFO

K

F

TB

TC

W18 (W38) Loop Control Word A. This word together with loop

control word B, W19 (W39), and loop expanded control word, W30

(W50), select the configuration for the loop. Bits 17 through 00 of loop

control word A are defined below and summarized in Figure 3.6 for loop

1 word W18 and loop 2 word W38.

W18 (W38) B17, B16 Block Identifiers. These two bits identify

this block as the loop block. B17 = 0 and B16 = 1 for loop 1. (For

loop 2, B17 = 1, B16 = 0.)

W18 (W38) B15 Source of Process Variable. Reset to 0 selects the

analog input as the process variable input for the loop. Set to 1

selects the value SET PV in word W09 (W16) as the process variable

for the loop.

W18 (W38) B14 Square Root of Process Variable. Reset to 0

inhibits the square root function. Set to 1 enables the normalized

square root of the process variable, (square root of PV x (square root

of 4095). Square root allows the linearization of differential pressure

type flow transducers.