Rockwell Automation 1771-PD PID MODULE (+DU) User Manual

Page 172

Application Example 1, Continuous Block

Transfer

Appendix B

BĆ13

Table B.C

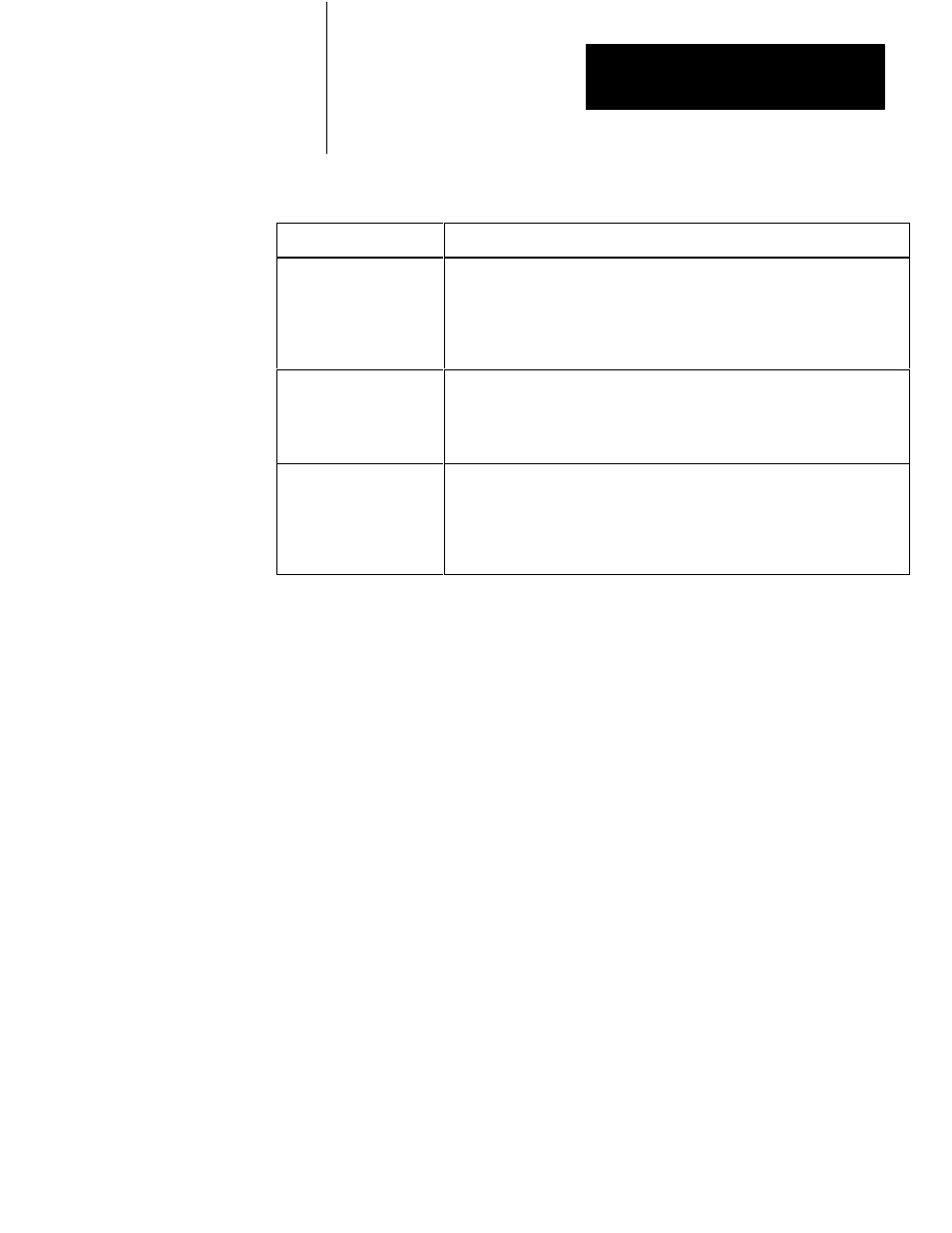

Recommended Output Annunicators

DESCRIPTION

FUNCTION

BLOCK TRANSFER

WATCHDOG Indicators

Program Address

012/01ĆREAD

012/00ĆWRITE

These indicators illuminate if a read or write block transfer does not occur within

a predetermined time. The time is determined by the preset value selected for

timer instructions 043

8

or 044

8

will timeĆout and energize indicators 012/02 or

012/00 depending upon whether the read or write function failed (rungs 9 and

25)

MANUAL MODE

Indicator

Program Address

012/04

This indicator illuminates when the manual control station (if used) is in the

manual mode (rung 18).

MODULE NOT

INITIALIZED

Indicator

Program Address

012/03

This indicator illuminates when the module has just been powered and is waiting

for operating parameters from the processor. The indicator turns off after the

first successful load/enter sequence (rung 11).

Specific Example

Once the program has been written, specific data of the dynamic block

and loop block can be entered into the respective data table files. This can

be done using the data monitor display mode of the industrial terminal.

Place the cursor on the file-to-file move instruction in rung 1 and press the

(DISPLAY)(1) Keys on the industrial terminal keyboard. The

hexadecimal display of the dynamic block and loop blocks will appear on

the screen. Enter the selected standard and expanded feature values.

On-line data change (SEARS)(5)(1) can be used.

The features and values that have been selected for this example problem

are tabulated below according to the control word in which the features

are programmed.

Master Control Word W01

Bits 17, 16 = 1

Both identifier bits must be 1.

Bit 15 = 1

Loop 1 only is selected.

Bit 14 = 0

Expanded features are not used.

Bit 13 = 0

Calibration bit must be 0.

Bit 12 = 0

Format is BCD.

Bit 11 = 0

Setpoint format is BCD.

Bit 10 = 0

Soft fault is programmed for manual

reset.