Rockwell Automation 1771-PD PID MODULE (+DU) User Manual

Page 52

Programming

Chapter 3

3Ć9

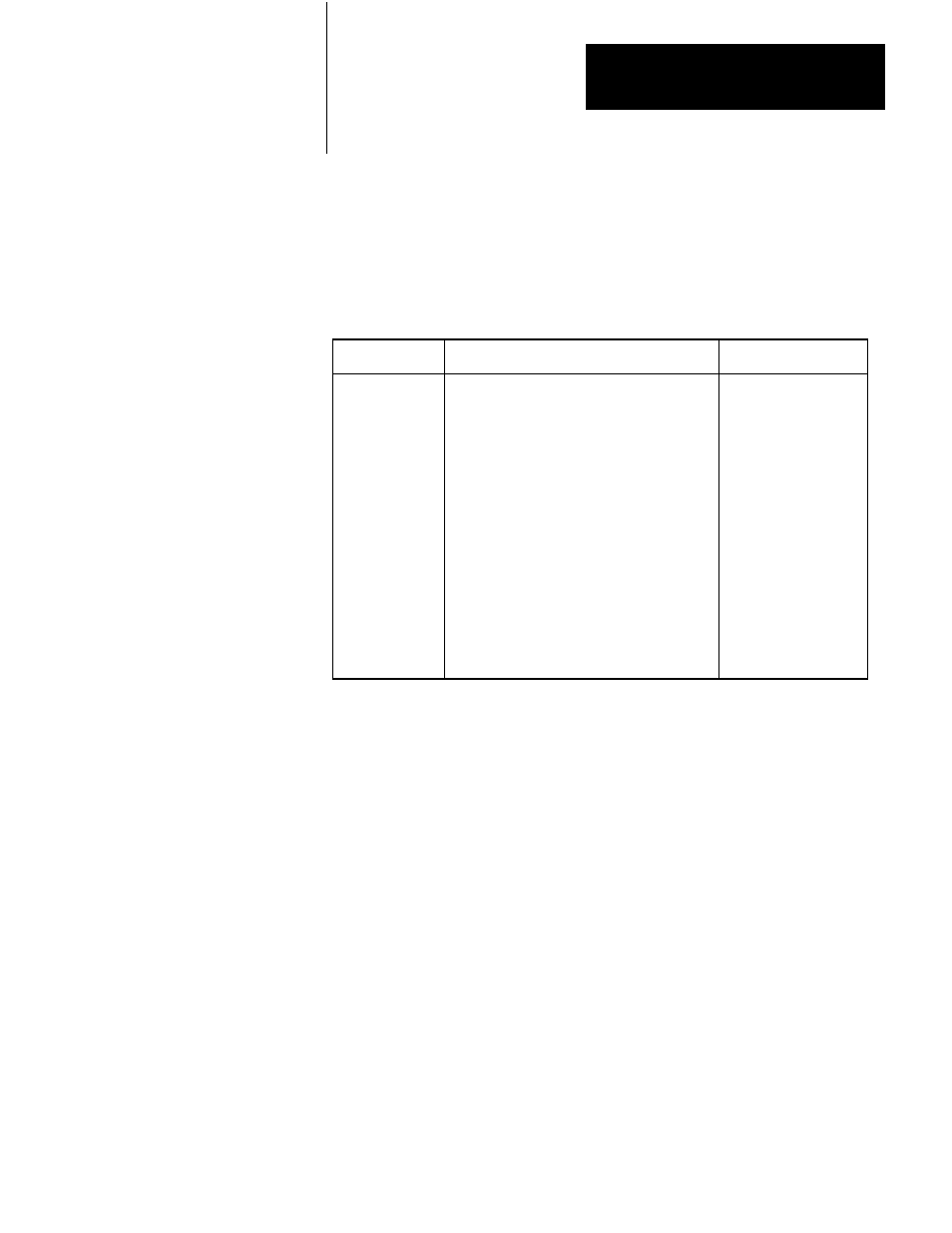

dynamic block, loop blocks and status block are listed in Table 3.J,

Figure 3.13 and Figure 3.14 found at the end of section title Word and Bit

Definitions.

Table 3.A

Dynamic Block Words

Word

Title

Abbreviation

W01

W02

W03

W04

W05

W06

W07

W08

W09

W10

W11

W12

W13

W14

W15

W16

W17

Master Control Word

Control Word

Dynamic Block Start Address

Loop 1 Block Start Address

Set Analog Output 1

Set Point 1

Proportional Gain 1

Bias 1

Set Process Variable 1

Set Feedforward Input 1

Loop 2 Block Start Address

Set Analog Output 2

Set Point 2

Proportional Gain 2

Bias 2

Set Process Variable 2

Set Feedforward Input 2

SET OUT 1

SP1

K

p

1

BIAS 1

SET PV1

SET FFI1

SET OUT 2

SP2

K

p

2

BIAS 2

SET PV2

SET FFI2

W01 Master Control Word. This word initiates all activities in the PID

module from power-up. This word programs the module configuration,

controls the initiation of the block transfer sequences, and can control the

setting of the analog outputs and the contact output. Bits 17 through 00

are defined below and summarized in Figure 3.5.

W01 B17, B16 Block Identifiers. Both bits must be set to 1 to

identify this block as the dynamic block.

W01 B15 Loop Select. [LE] Reset to 0 selects both loop 1 and loop

2. Set to 1 selects loop 1 only. When loop 1 and loop 2 are selected,

all words in the dynamic block are used and both loop blocks must

be programmed. When loop 1 is selected, only words W01 through

W10 of the dynamic block are used and the loop 1 block must be

programmed.

W01 B14 Standard/Expanded Features. [XF], [LE] Reset to 0

selects standard loop features. When the stand loop is selected, loop

1 words W30 through W36 and loop 2 words W50 through W56 are

NOT used by the module. Set to 1 selects expanded loop features