Rockwell Automation 1771-PD PID MODULE (+DU) User Manual

Page 179

Application Example 1, Continuous Block

Transfer

Appendix B

BĆ20

Program PLCĆ3 Processors

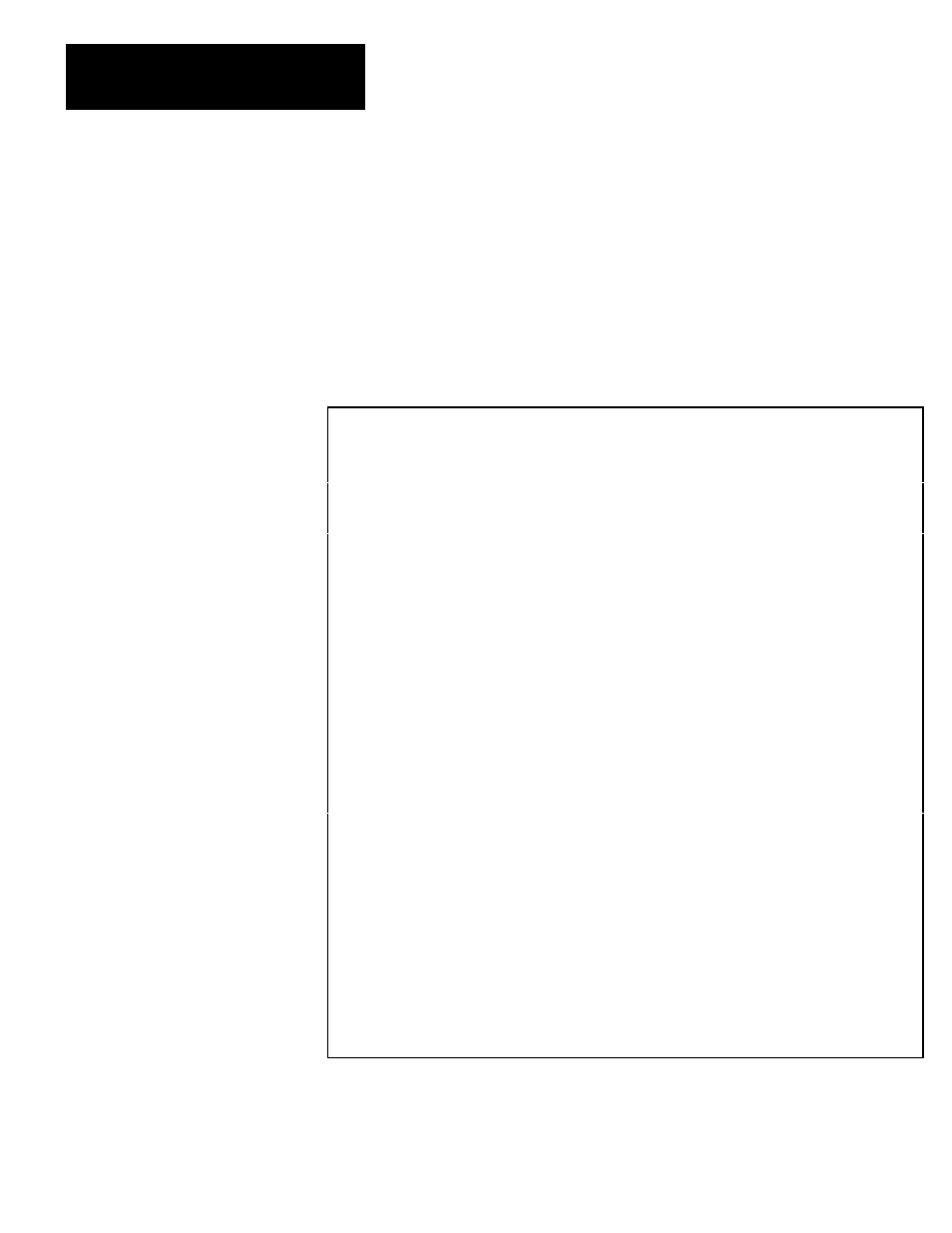

The PLC-3 program for continuous block transfer is presented in figure

B.6 Worksheets for the Dynamic block (figure B.4) and Loop 1 Block

(Figure B.5) also apply to the PLC-3 program. File storage addresses are

tested in Table B.D.

Table B.D

PLCĆ3 File Storage Addresses

(shown in hex)

Start = WB000:0000

Word number

0

1

2

3

4

5

6

7

00000

0001 E180 0000 0001 0012 0000 3303 0050

00008

0000 0000 0000 0026 0000 0000 0000 0000

000116

0000 0000 4000 0000 0000 0000 4095 0000

00024

0000 0000 0000 0000 0000 4095 0000 0000

00032

0000 0000 0000 0000 0000 0000 8000 0000

00040

0000 0000 0000 0000 0000 0000 0000 0000

00048

0000 0000 0000 0000 0000 0000 0000 0000

00056

0000 0000 0000 0001 0000 0450 2203 1101

00064

1100 1100 0000 0000 0000 0000 0000 0000

00072

0000 0000 0000 0000 0000 0000 0000 0000

Dynamic Block Ć binary file 0, words 1 thru 17

start location: 00000000 00000001 in binary, 0001 in hex

Loop 1 Block Ć binary file 0, words 18 thru 36

start location: 00000000 00010010 in binary, 0012 in hex

Loop 2 Block Ć binary file 0, words 38 thru 56

start location: 00000000 00100110 in binary, 0026 in hex

Status Block Ć binary file 0, word 57 thru 74

Input Buffer Ć binary file 2, words 0 thru 20

Block Transfer Control File Ć Binary file 3

Module Location: rack 2, module group 1

NOTE: Block transfer control file must be the same for the read and write block transfer instructions.

Binary file 0 word 0 is used to store the dynamic block start address (rung l3 in the continuous block

transfer program, rung 23 in the periodic block transfer program).