Rockwell Automation 1785-LTx,D17856.2.1 Classic PLC-5 Programmable Controllers Users Manual User Manual

Page 77

Planning Your System Programs

Chapter 6

6-6

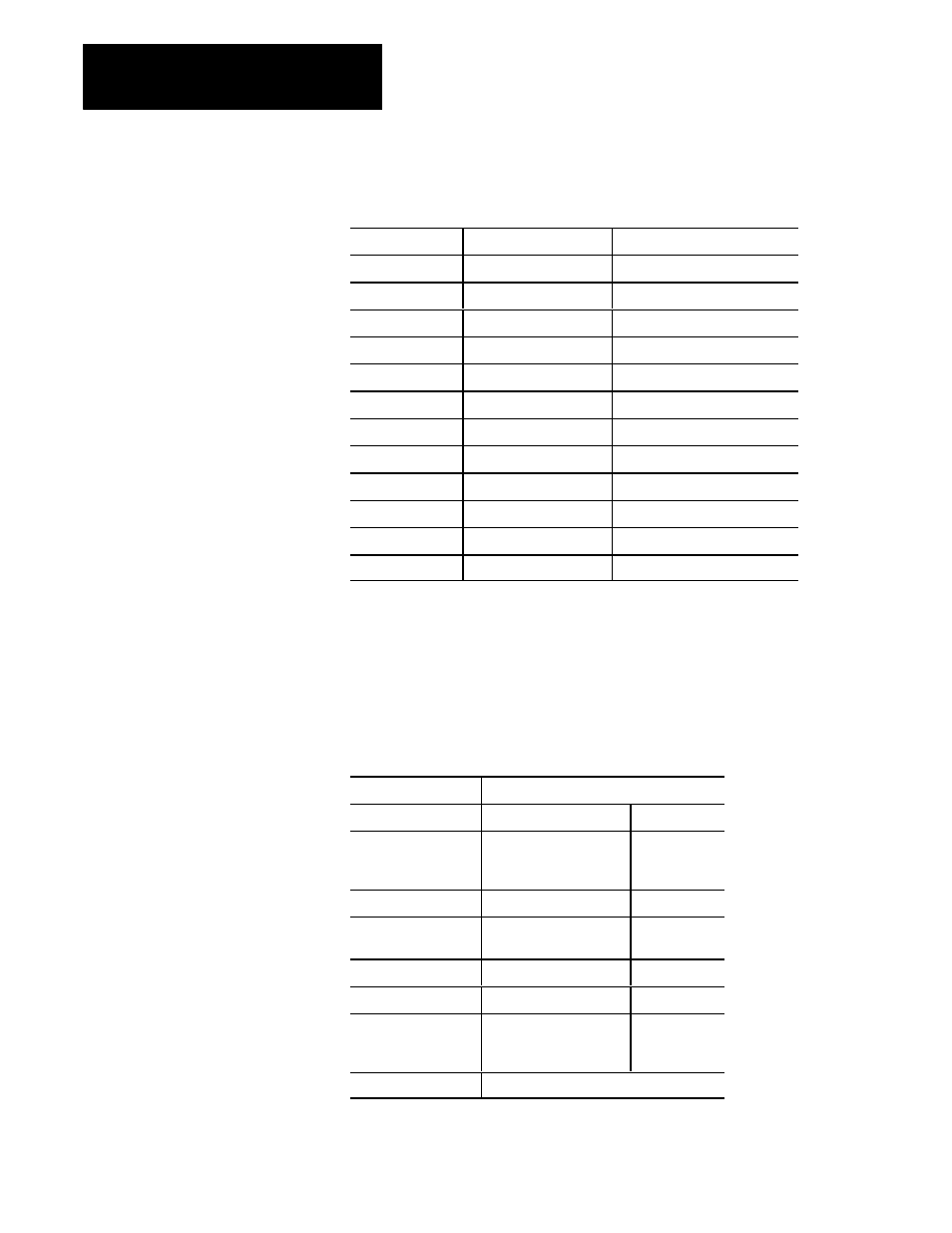

Table 6.C

Hardware Requirements for the Inputs and Output of the Drill Example

Input

Part

Description

AUTO

selector switch

select automatic mode

LS1

N.O.

limit switch

part in place

LS2

N.C.

limit switch

drill station home

LS3

N.O.

limit switch

drill motor on

LS4

N.O.

limit switch

drill station at full depth

LS5

N.O.

limit switch

cycle complete

DSF

drive motor

move drill station forward

DSB

drive motor

move drill station back

DM

drill motor

drill motor on

CL1

electric clamp

clamp 1 on

CMF

drive motor

move conveyor forward

TMR1

timer

dwell timer

Use the hardware requirements (with the functional specification) to

match the inputs and outputs with the actions of the process. Table 6.D

shows the hardware requirements with the general description of the drill

machine example.

Table 6.D

List of Conditions and Actions for the Drill Example

When this happens:

This happens:

AUTO switch closes

Conveyor moves forward

(CMF = on)

LS1 closes

Conveyor stops

Clamp holds wood

Drill station advances

(CMF = off)

(CL1 = on)

(DSF = on)

LS3 closes

Drill motor starts

(DM = on)

LS4 closes

Drill station stops

Dwell timer starts

(DSF = off)

(TMR1 = on)

Timer done

Drill station backs up

(DSB = on)

LS3 opens

Drill motor stop

(DM = off)

LS2 opens

Drill station stops

Clamp releases wood

Conveyor starts

(DSB = off)

(CL1 = off)

(CMF = on)

LS5 closes

Wood is ejected