Rockwell Automation 1785-LTx,D17856.2.1 Classic PLC-5 Programmable Controllers Users Manual User Manual

Page 26

Choosing Hardware

Chapter 2

2-7

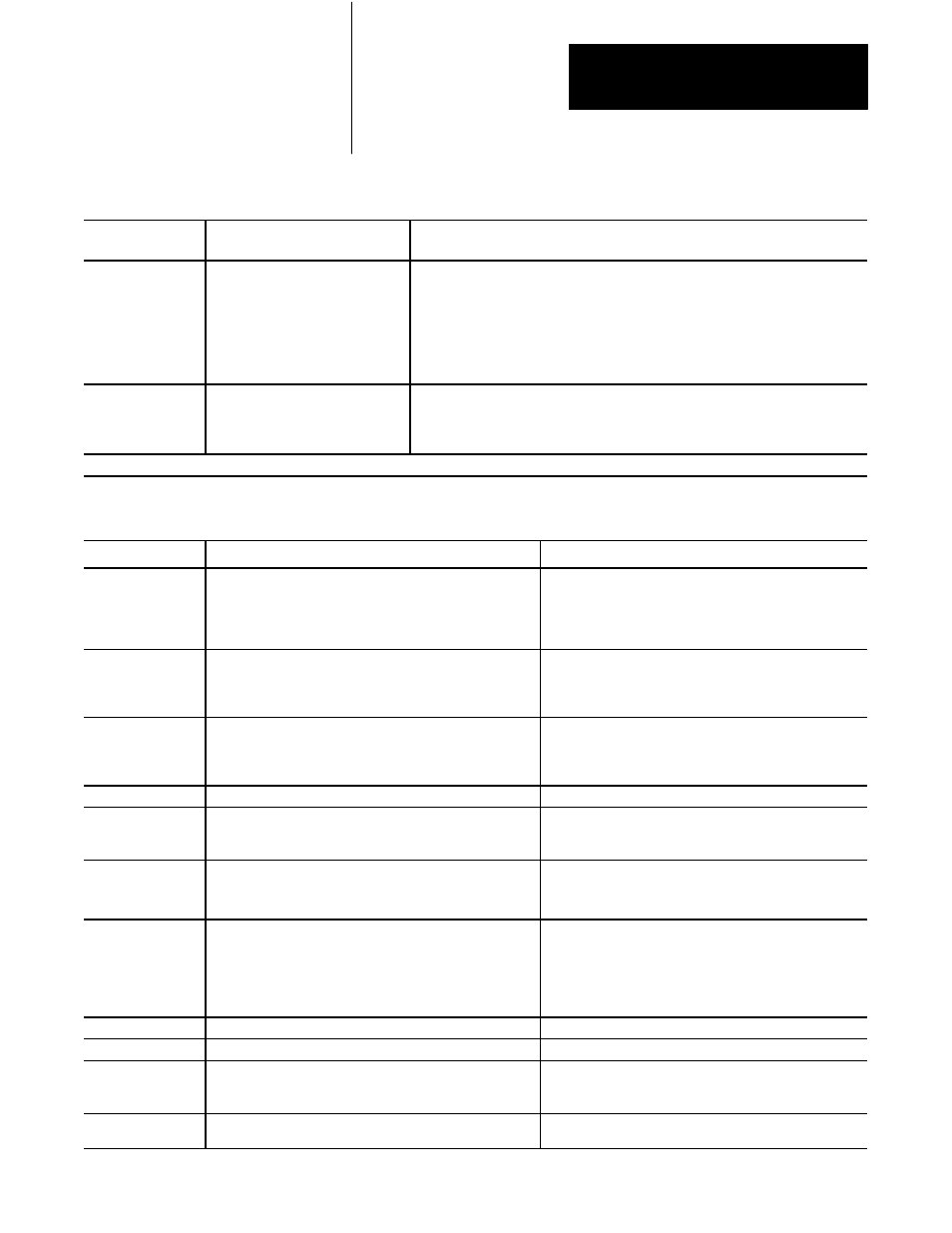

Table 2.G

Guidelines for Selecting an Operator Interface

Choose this

operator interface:

For these types of

operations (examples):

Explanation:

PanelView

1

Starts/stops, auto/manual operations,

setpoints, outputs, alarms

Used as an operator window to enter commands that make process adjustments such

as starts/stops and loop changes. Can also be used for alarming operations. Can

communicate with a single PLCĆ5 processor on a remote I/O link. Has a fixed number

of devices and amount of data that it can handle. Has builtĆin error checking. Is an

industrialĆhardened CRT with pushbuttons, solid state memory and processor, and no

moving parts (i.e., disk drive).

Utilizes pass through, which is the ability to download/upload via DH+/remote I/O links.

ControlView

1

Store, display, and manipulate data

on process performance (i.e., trends,

process graphics, formulas, reports,

and journals)

Used as an operator window that communicates with a PLCĆ5 processor on Data

Highway Plus (DH+) link. Designed for use as an information link. Can communicate

to multiple PLC processors. ControlView is a software package that runs on an IBMr

DOSĆbased personal computer.

1

Refer to your local AllenĆBradley sales office or AllenĆBradley distributor for more information on PanelView and ControlView.

Table 2.H

Comparison of PanelView and ControlView Features

Category

PanelView

ControlView

Communication with

PLC processor

Remote I/O

5 block transfers per terminal maximum (32 words per transfer)

1 discrete transfer per terminal (64 words maximum, one way)

This is 8 racks of transfer

DH+ link

Data Highway

Data Highway II Native Mode

Graphics

Character graphics

Create screens with PanelBuilder software

Monochrome or color (8 of 16 colors displayed at a time)

Pixel Graphics

Create screens with Mouse Grafix editor option or C Toolkit

EGA, VGA, or equivalent with 256K RAM

Monochrome or color monitor

Number of

Screens per

Terminal/Workstation

8 to 12 screens of medium complexity typical

200 objects maximum per screen

Limited by terminal memory size: 128 Kbytes

Limited only by hard disk capacity

50 data entry locations per screen

50 tags per command list per screen

300 tags/points maximum per screen

Data Capacity

200 objects maximum per screen

10,000 points maximum in database

Communication

Rate

Limited by blockĆtransfer and discreteĆtransfer timing

Depends on PLC processor and remote I/O link size

8 scan classes, each with userĆconfigurable foreground and

background update times; limited by performance of Data

Highway, DH+, or Data Highway II link

Hardware

Keypad or Touchscreen terminals, color or monochrome

AllenĆBradley, IBM, or compatible computer required for

PanelBuilder software

AĆB, IBM, or compatible computer with 286 or 386

processor, math coprocessor, hard disk required at each

operator station

Programming

PanelBuilder software

MenuĆdriven with fillĆinĆtheĆblank information entry

Use PanelBuilder to create application file that defines

screens, messages, alarms, then download application file to

PanelView terminal

Create data base online via the menu. MenuĆdriven,

fillĆinĆtheĆblank information entry, or import data via the ASCII

import capability

Create screens with the mouse GRAFIX editor option or C

toolkit option

Messages

496 maximum per terminal

Not Applicable

Alarms

496 maximum per terminal

2000 points with Alarming option

Security

8 levels

16 levels with individual operator login capability

Individual objects with security

Screen lockout

Options

Remote serial port

EEPROM or EPROM memory

Lots of software options