Planning cabling – Rockwell Automation 1785-LTx,D17856.2.1 Classic PLC-5 Programmable Controllers Users Manual User Manual

Page 40

Placing System Hardware

Chapter 3

3-5

To plan a raceway layout, do the following:

categorize conductor cables

route conductor cables

Categorize Conductors

Segregate all wires and cables into categories as described in the Industrial

Automation Wiring and Grounding Guidelines, publication 1770-4.1. See

the installation data for each I/O module that you are using for information

about its classification.

Route Conductors

To guard against coupling noise from one conductor to another, follow the

general guidelines for routing cables described in the Industrial

Automation Wiring and Grounding Guidelines, publication 1770-4.1. You

should follow the safe grounding and wiring practices called out in the

National Electrical Code (NEC, published by the National Fire Protection

Association, in Quincy, Massachusetts), and local electrical codes.

DH+ Link Cabling

At a DH+ transmission rate of 57.6 kbps, do not exceed 3,048 cable-m

(10,000 cable-ft) for a trunkline cable length or 30.5 cable-m (100 cable-ft)

for a dropline cable length.

Remote I/O Link Cabling

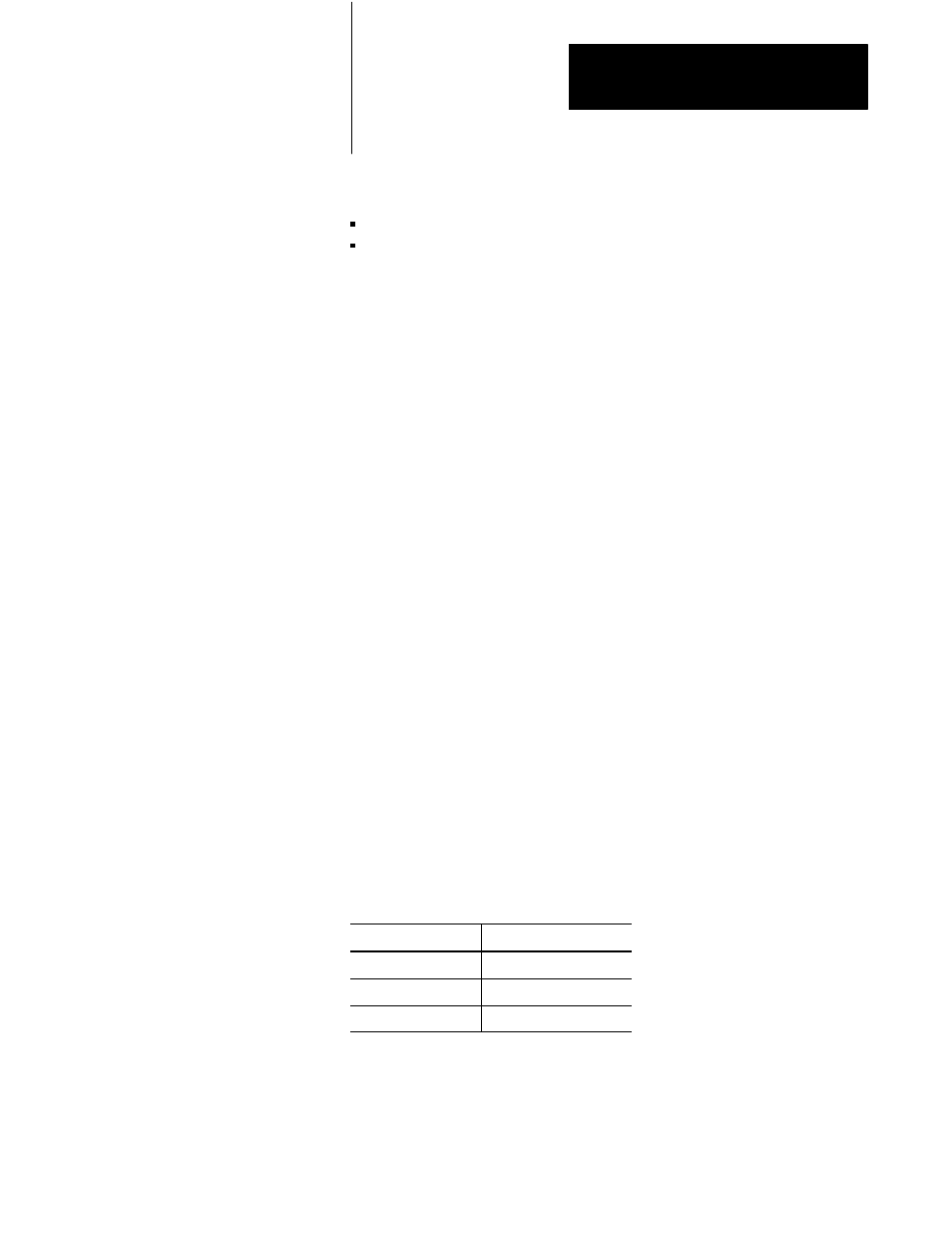

Refer to Table 3.B for remote I/O link trunkline cable length restrictions.

Table 3.B

Maximum Cable Lengths per Communication Rate

Transmission Rate

Maximum Cable Length

57.6 kbps

3,048 m (10,000 ft)

115.2 kbps

1,524 m (5000 ft)

230.4 kbps

762 m (2500 ft)

Important: All devices on the remote I/O link must be communicating at

the same transmission rate.

Planning Cabling