1785-6.2.1, 9 - calculating program timing, Calculating program timing – Rockwell Automation 1785-LTx,D17856.2.1 Classic PLC-5 Programmable Controllers Users Manual User Manual

Page 118

Chapter

9

9-1

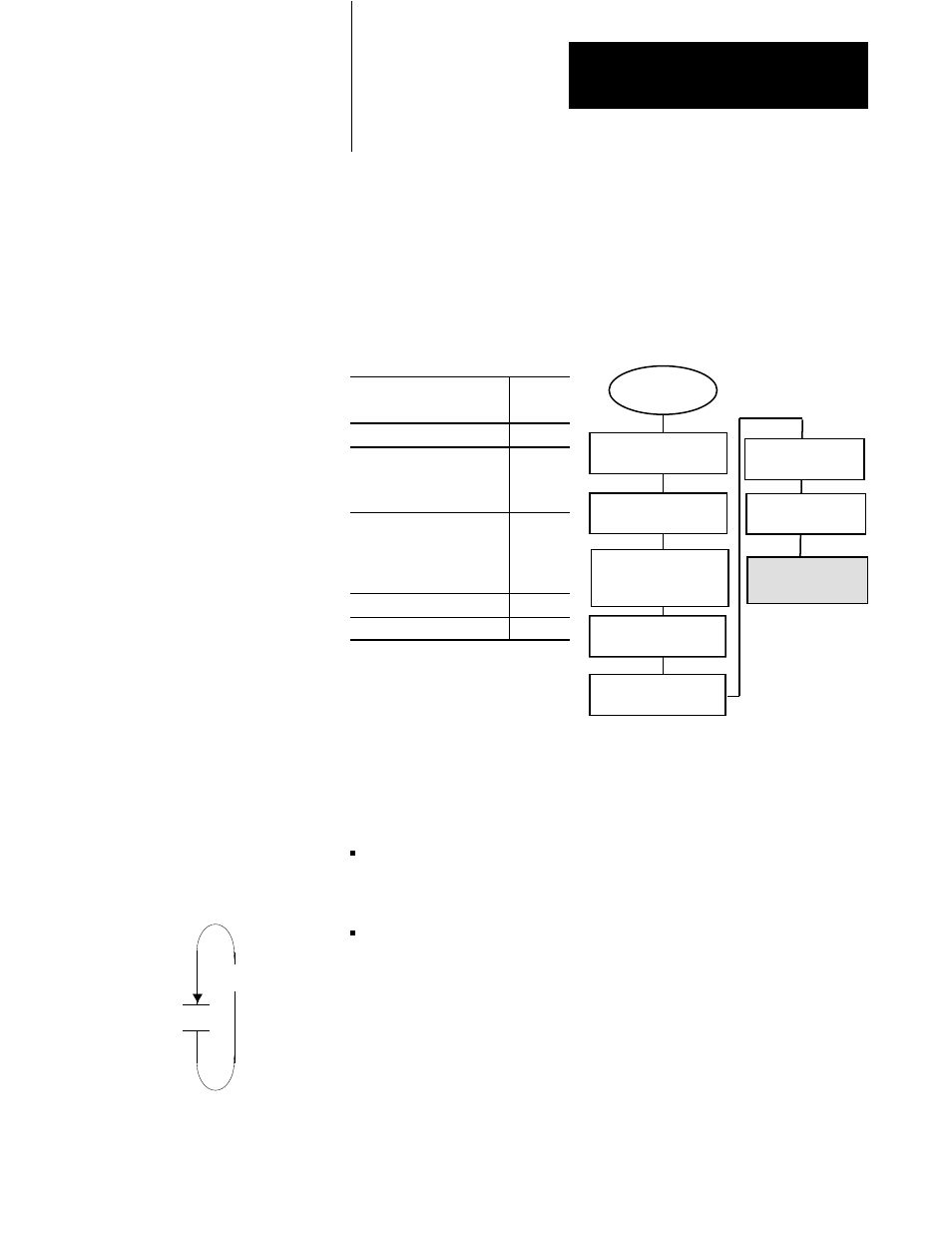

Calculating Program Timing

This chapter provides information to help you determine the program

timing for your PLC-5 programmable controller system.

If you want to read about: Go to

page:

PLCĆ5 processor scan time

9Ć1

I/O update timing:

Transfer discrete data

Transfer block data

Instruction timing and

memory requirements:

Bit and word instructions

File instructions

Program constants

Direct and indirect elements

The basic function of a programmable controller system is to read the

status of various input devices (such as pushbuttons and limit switches),

make decisions based on the status of those devices, and set the status of

output devices (such as lights, motors and heating coils). To accomplish

this, the PLC-5 processor performs two primary operations:

program scanning—where

- logic is executed

- housekeeping is performed

I/O scanning—where input data is read and output levels are set

Program Scanning

The program scan cycle is the time it takes the processor to execute the

logic scan once, perform housekeeping tasks, and then start executing

logic again.

The processor continually performs logic scanning and housekeeping. You

can monitor the program scan time using the processor status screen.

Housekeeping activities for most PLC-5 processors includes:

Chapter Objectives

Introduction to Classic

PLCĆ5 Processor Scanning

Housekeeping

Logic Scan

System Design

Determined

Choosing

Communication

Transferring Discrete

and Block Data

Planning Your

System Programs

Selecting Interrupt

Routines

Calculating Program

Timing

Choosing Hardware

Placing System

Hardware

Assigning Addressing

Mode, Racks,

and Groups