Rockwell Automation 1785-LTx,D17856.2.1 Classic PLC-5 Programmable Controllers Users Manual User Manual

Page 104

Transferring Discrete and BlockĆTransfer Data

Chapter 8

8-9

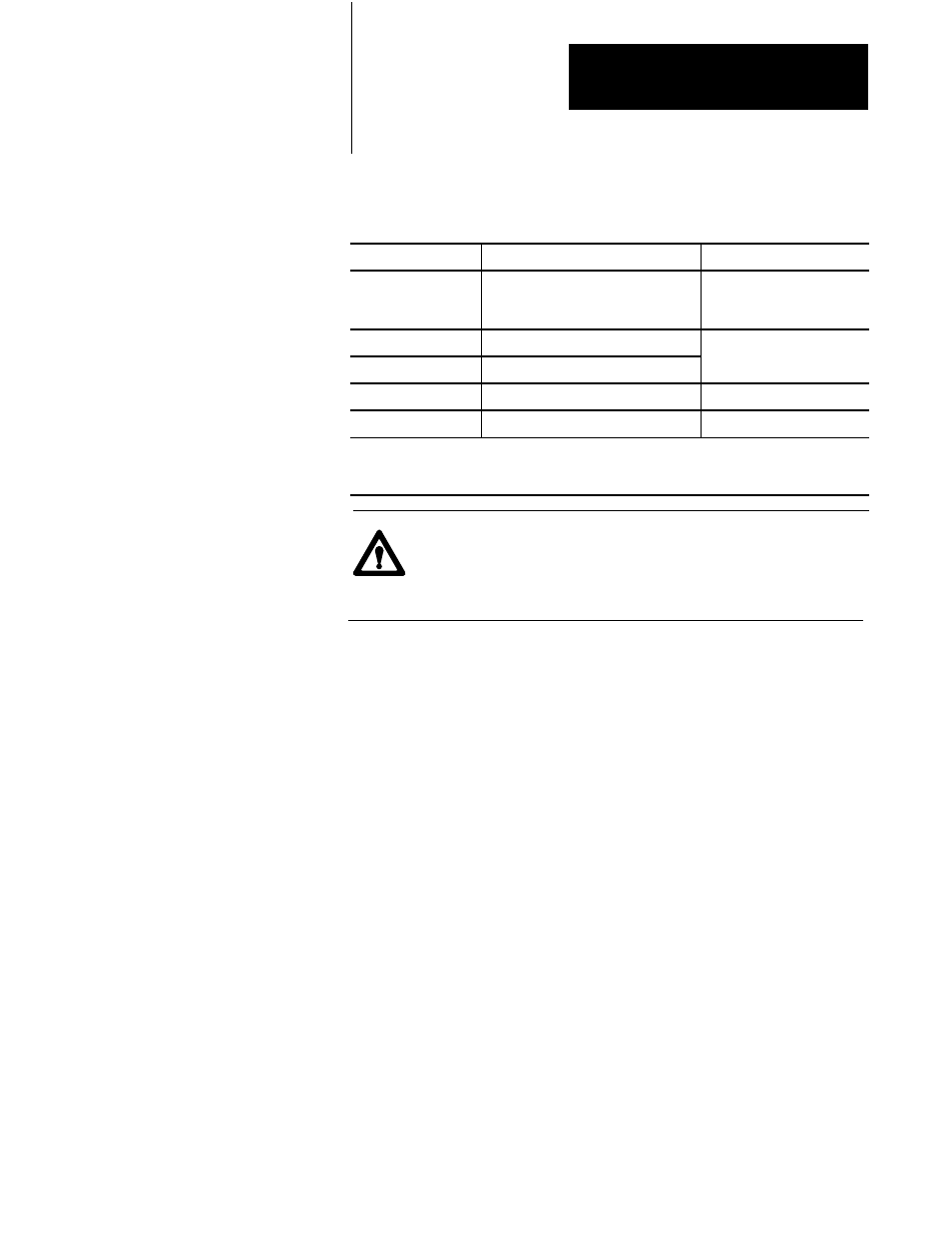

Table 8.M

Addressing Tips for Adapter/Supervisor Block Transfers with a PLCĆ5/12,

Ć5/15, or Ć5/25 AdapterĆMode Processor

BTR/BTW Parameter BTR/BTW in Supervisor

BTR/BTW in Adapter

Rack

PLCĆ2/30: 1Ć7 octal

PLCĆ3: 0Ć77 octal

PLCĆ5/25: 1Ć7 octal

Must be 3

1

Group

0

Must be 0

Module

0

Length

Must be 0

Number of words transferred

Continuous

Yes (PLCĆ5 and PLCĆ5/250 only)

Yes

1

If you need rack 3 I/O for the adapterĆmode processor's local I/O, then you must specify an

adapter image file and block transfers can not be used between the supervisory and

adapterĆmode processor.

ATTENTION: To guarantee the correct destination of

block-transfer data, program only one set of bidirectional block

transfers between supervisory and adapter-mode processors

with PLC-5/12, -5/15, and -5/25 processors in adapter mode.

Important: If you are using a PLC-5/12, -5/15, or -5/25 processor, set the

supervisory processor’s communication rate for remote I/O to 57.6 kbps.

Block transfers between adapter and supervisory processors transfer data

between data table addresses. If you want to transfer processor-resident

local I/O data of the adapter mode processor to a supervisory processor or

if you want to transfer data from the supervisory processor to processor-

resident local I/O of the adapter mode processor, you must use MOV or

COP instructions within the adapter-mode processor to move the data in or

out of the data file used in the adapter block-transfer instruction.

Figure 8.5 shows data transfers from a supervisory processor to a

PLC-5/12, -5/15, or -5/25 adapter-mode processor to a local block-transfer

module and vice versa.