Organizing a machine example – Rockwell Automation 1785-LTx,D17856.2.1 Classic PLC-5 Programmable Controllers Users Manual User Manual

Page 75

Planning Your System Programs

Chapter 6

6-4

Organizing a Machine Example

This section uses an example of a specific machine operation to show how

to identify conditions and actions and how to group the actions into steps

of machine operation.

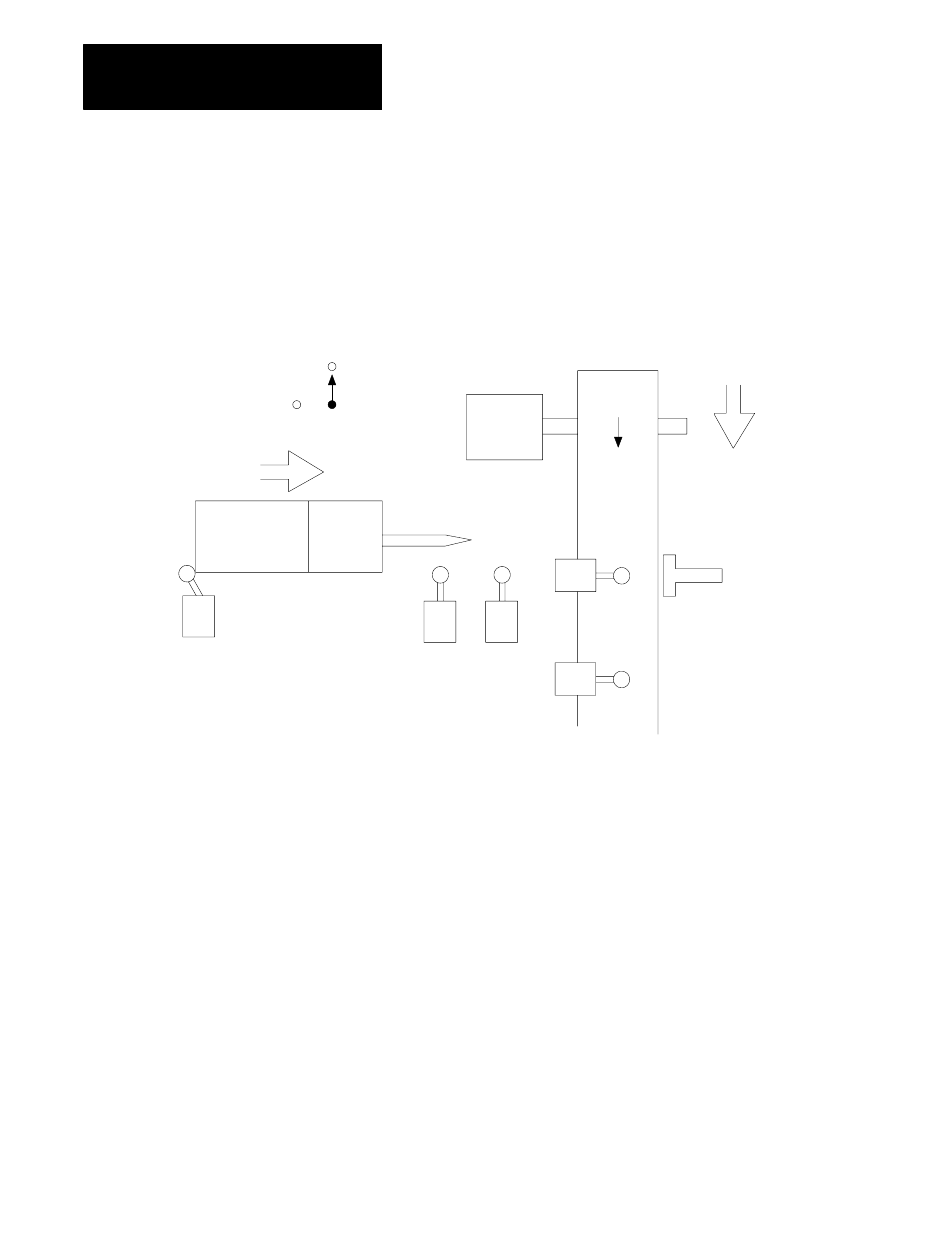

Figure 6.1

Hardware Block Diagram and Description of Machine Process

FW D

Conveyor

M otor

O FF

AUTO

Advance

Assem bly

Drill

M otor

N C

N O

N O

LS1

LS5

FW D

Clam p

CL1

LS4

LS3

LS2

Held O pen

. .

. .

. .

N O

. .

N O

. .

FW D

L oad

St a t i on

l oad

St a t i on

U n

A description of this operation might be as follows:

1.

The operator starts the conveyor by selecting AUTO.

2.

The operator puts a block of wood onto the conveyor.

3.

The wood moves into position and actuates LS1.

4.

When the wood is in position:

a.

the conveyor stops

b.

CL1 clamps the wood

c.

the drill station moves forward

5.

The drill station moves forward and closes LS3. This

action turns on the drill motor.

6.

The drill station moves to full depth and closes LS4. This action:

a.

stops forward motion of the drill station

b.

initiates a 2Ćsecond dwell

7.

The drill station backs up after the 2Ćsecond dwell.

8.

The drill motor stops when LS3 is released.

9.

The drill station reaches home position and opens LS2. This action:

a.

stops the reverse motion

b.

opens the clamp

c.

starts the conveyor forward

10.

The wood is ejected when LS5 toggles to indicate that the cycle is complete.