Programming a 1-axis profile – Rockwell Automation 1771-QA Stepper Positioning Assembly User Manual User Manual

Page 80

4–2

Example Programs

Publication 1771-UM002A–EN–P – May 2000

Programming a 1-Axis Profile

The task of programming can be simplified by documenting the

desired positioning profile in the following manner.

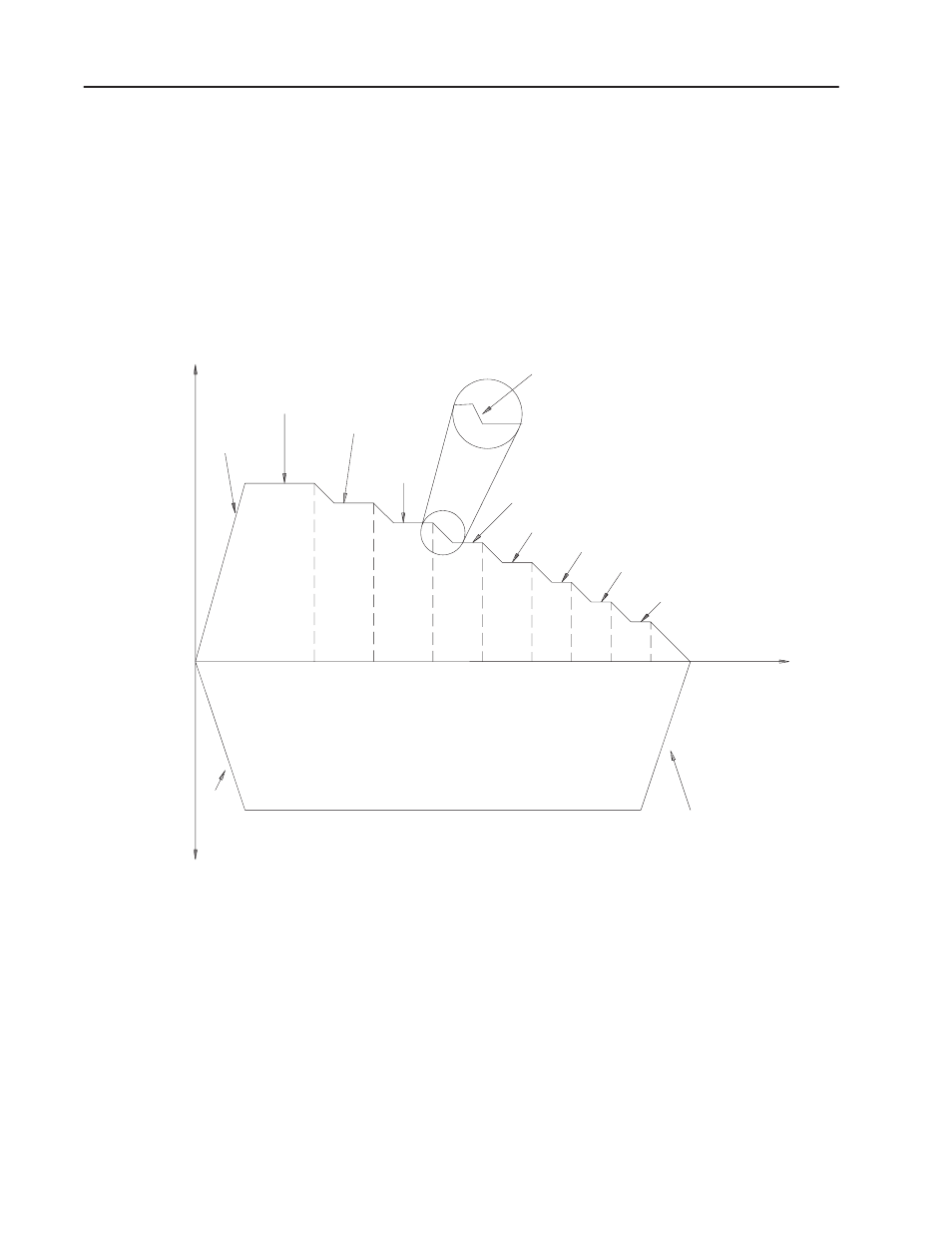

1. Sketch the positioning profile and designate the ramp time, final

rate, final position, and decel values as needed (Figure 4.1).

Decide which of the three operating modes (continuous,

independent or single step) should be used.

Figure 4.1

Example 1-Axis Profile (Continuous Mode)

Rate

RT=

FR=2000 P/Sec

FR=1800 P/Sec

FR=1500

Moves 2–8

FR=1100 P/Sec

FR=800 P/Sec

FR=200 P/Sec

FR=100 P/Sec

FR=050 P/Sec

RT=

Position

Move #1

2

3

4

5

6

7

8

9

Move 10

FR=2000 P/Sec

RT=

Reverse

Forward

6000

9000

12000

15000

16500 17500 18500 19000

19200

10602

3.00 Sec

2.00 Sec

3.00 Sec

RT=1.00 Sec

P/Sec

2. Log all move data such as ramp time, final rate, final positions

and decel values as needed, and offset/preset data if used. Use

the Moveset Data form found at the end of this manual for each

positioning profile moveset (Figure 4.2) or jog moveset (Figure

4.3).

3. Write the ladder diagram program using the example as a guide

(Figure 4.4).

4. Enter move data into corresponding data table files associated

with file A of each file-to-file move instruction using the data

monitor mode of the industrial terminal (Figure 4.5). File R

displays the data moved to the write block transfer file during

operation and should be ignored during programming.