Assembly and installation, Chapter, General input considerations – Rockwell Automation 1771-QA Stepper Positioning Assembly User Manual User Manual

Page 11

Chapter

2

Publication 1771-UM002A–EN–P – May 2000

Assembly and Installation

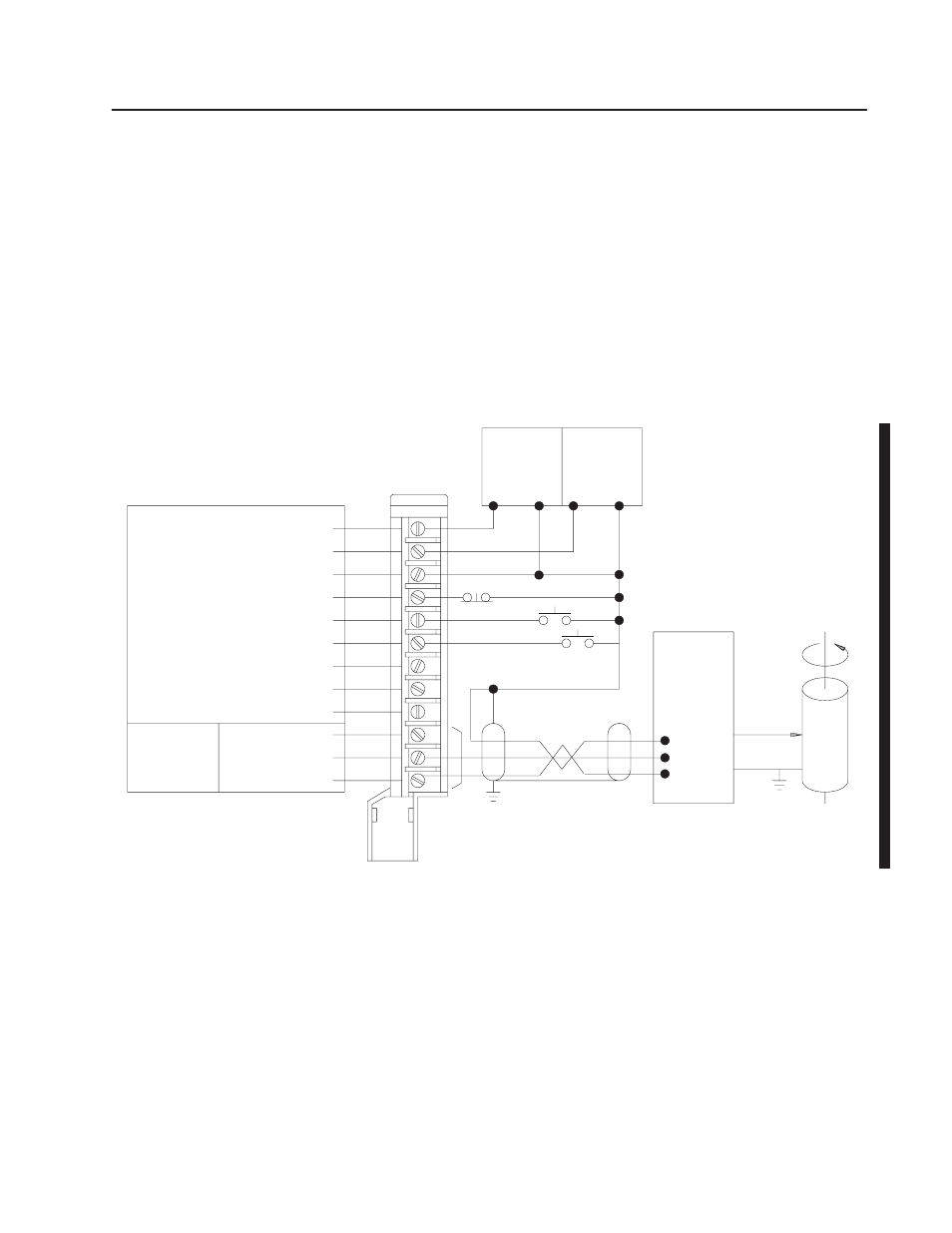

The stepper positioning assembly can be wired for 1-axis operation

with a stepper translator and motor as shown in Figure 2.1. One

stepper controller module can control up to three pulse output

expander modules installed in the same chassis. When the

application calls for 2-or 3-axis control, each additional expander

module should be wired as shown in Figure 2.1. No more than one

stepper controller module can operate in an I/O chassis.

Figure 2.1

Typical 1-Axis Connection Diagram

+ DC Input Supply

10510

Output

Stepper

Pulse Output

Input

Mechanical

Stepper

Rate Pulses/

+ DC Output Supply

Common

Stop Input

Jog Forward Input

Jog Reverse Input

Not Used

Not Used

Not Used

Rate

Fwd Dir

Rev Dir

Rev Rate

Fwd Rate

Not Used

Motor

Load

Translator

and

Power

Supply

+

–

+

–

Expander Module

Field Wiring Arm

1771–WB

Directional Signals

1

2

3

4

5

6

7

8

9

10

11

12

NEC Class 2

Power

Supply

NEC Class 2

Power

Supply

Pulse output expander modules can be controlled manually by the

use of switch inputs for stop, jog forward and jog reverse. The stop

switch will cause output pulses to the corresponding axis to cease

instantaneously. Jog switches are operational only when the

corresponding axis is at rest.

General

Input Considerations