Care and use manual – Waters Analytical Columns and Cartridges User Manual

Page 4

[ Care and Use ManUal ]

Analytical Columns and Cartridges

4

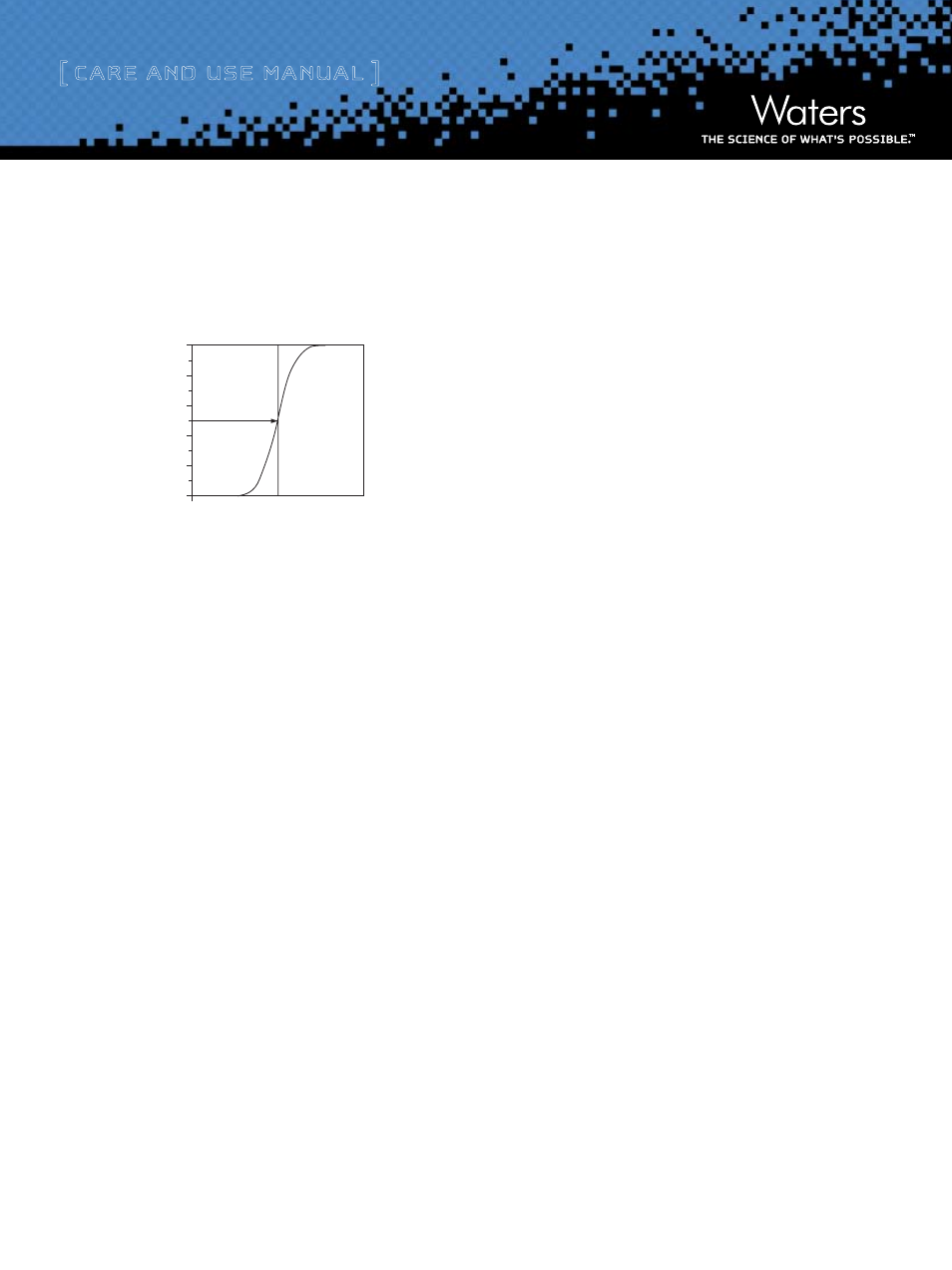

A second effect, called dwell volume is observed with gradient analy-

sis. In this case, the lower flow rate causes the gradient front to take

longer to reach the head of the column. To measure the dwell volume

for your system, refer to the procedure, For Gradient Analysis, below

and refer to Figure 3.

Figure 3: Determination of Dwell Volume

For Gradient Analysis:

1. Replace the column with a zero dead volume union.

2. Determine the gradient-delay or dwell volume for your system by

performing a dwell volume test. Prepare eluent A (pure solvent), and

eluent B (solvent plus sample).

3. Equilibrate system with eluent A until a stable baseline is achieved.

Switch to 100% eluent B and record the time at half height of the step.

Refer to Figure 3 for an illustration.

4. Modify your HPLC system in order to minimize the dwell volume

according to the System Modifications Guidelines section. The dwell

volume should be less than 1 mL for small volume columns.

System Modification Guidelines:

1. Use 0.25 mm (0.009-inch) tubing between pump and injector.

2. Use a microbore detector flow cell, for example, Waters Tuneable

UV-VIS Absorbance Detector with a 2.6 μL volume) for the 2.1 mm

columns. Recall that due to the shorter path length, detector sensitivity

is reduced to achieve lower band spread.

3. Use 0.12 mm (0.005-inch) i.d. tubing for the 2.1 mm column to

minimize dead volume. With careful plumbing, standard 0.25 mm

(0.009-inch) i.d. tubing can be used with the 3.0 mm column.

4. Use a manual injector with a low dead volume, for example, Rheodyne

Model 7725.

IV. Column maIntenanCe

This section describes routine column maintenance procedures that

should be followed to maximize the lifetime of your Waters column.

The procedures are described in detail below:

a. Caring for the Column

To ensure the continued high performance of your Waters column,

follow these guidelines:

• Protect steel columns, cartridge columns and column segments from

contaminants with a Waters Sentry Guard Column or a Waters Guard-

Pak™ Insert.

• Use Waters Sep-Pak

®

solid-phase extraction cartridges or Waters

Oasis

®

Cartridges to clean up your sample prior to analysis.

• Make sure that solvents are miscible when changing mobile phases.

This will prevent phase separation or precipitation.

• Always degas and filter mobile phases through a 0.22 μm membrane

filter. Acrodisc

®

filters by Gelman Sciences are recommended.

• Do not exceed an operating pressure of 40 MPa (400 atm or 6000 psi)

for steel columns, or 13 MPa (130 atm or 2000 psi) for Radial-Pak™

column segments.

b. Cleaning and Regenerating the Column

A shift in retention or resolution may indicate contamination of

the column. Flushing with an organic solvent is usually sufficient to

remove the contaminant.

If system back pressure increases with usage, replace the guard col-

umn. If you are not using a guard column, replace the inlet frit. If the

problem continues, the column may be plugged with a contaminant

that needs to be dissolved with an appropriate solvent. For example,

proteinaceous material can be removed with repeated 200 μL

injections of dimethylsulfoxide.

If the flushing procedure does not solve the problem, wash the

column with a sequence of progressively more nonpolar solvents. For

example, switch from water to tetrahydrofuran (THF) to methylene

chloride. Return to the standard mobile phase conditions by reversing

the sequence.

1.0

0.8

0.6

Height

Volume (µL)

0.4

0.2

0.0

Dwell

Volume