Care and use manual – Waters Pico-Tag Amino Acid Analysis Column User Manual

Page 4

[ Care and Use ManUal ]

Pico•Tag Amino Acid Analysis Column

4

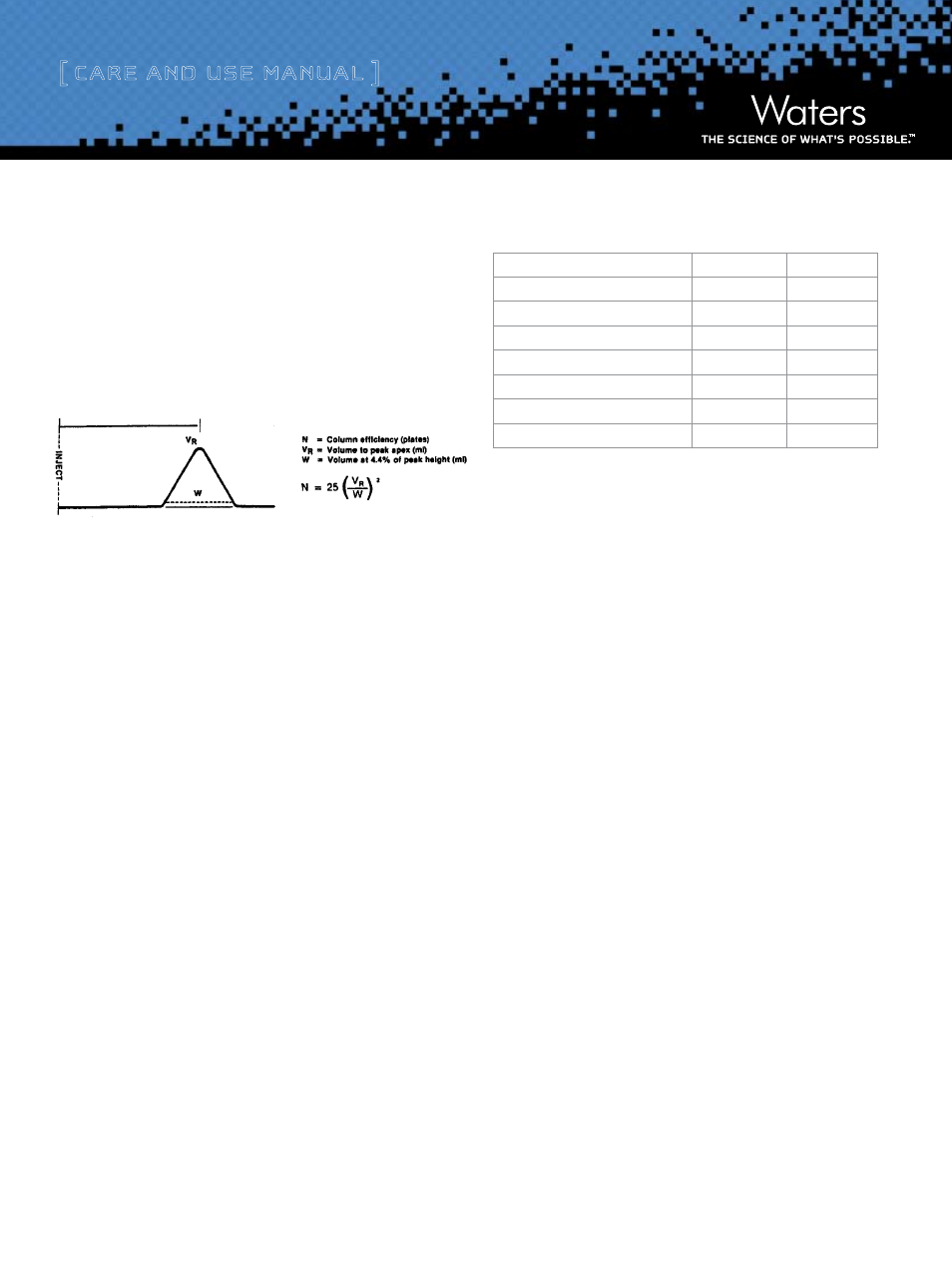

IV. column eFFIcIency

Waters measures column efficiency by using the 5-sigma method. Plate count,

as an expression of efficiency, is determined by measuring the peak width at

4.4% of the peak height. Unlike half-peak height and tangent methods used by

other manufacturers, this stringent method takes into con-sideration naturally

occurring peak asymmetry.

Figure 3. Column Efficiency

V. test condItIons

Columns are thoroughly tested in our quality control laboratories for adher-

ence to our specifica-tions. Since slight variations in your results will occur

depending on the equipment used, test sam-ple makeup and equipment

settings and condition, perform the test sample run given here for your new

column and record the results (retention time and the settings used) before

attempting the first analysis. Use these results for comparison throughout the

life of your column.

NOTE: BE SURE TO RECORD RESULTS AND INSTRUMENT SETTINGS (AND

CONFIGURATIONS) TO ALLOW EXACT REPRODUCTION AND COMPARISON IN

THE FUTURE.

Test Sample:

Acenaphthene (0.05% in acetonitrile)

Solvent:

Pico•Tag Eluent B

Flow Rate:

1.0 ml/min

Chart Speed:

10 cm/min

Injection Volume:

15 µl

Detection:

254 nm @ 0.5 AUFS

VI. recommended sPAre PArts (steel columns)

* Included as components of 3.9 mm Filter Replacement Kit

VII. WArrAnty

Waters warrants its quality manufactured columns in accordance with the

following terms and conditions. Waters will repack or replace the column (at

our discretion) at no cost if it fails to perform satisfactorily and Waters is noti-

fied within 90 days of receipt. Columns being returned must have prior Return

Authorization granted by Waters Customer Service Department. Approval is

subject to the following exclusions:

•

Physical damage to the column due to misuse or abuse.

•

Chemical damage to the packing material due to operating with incom-

patible solvents, buffers, or pH.

•

Physical damage to the packing material due to operation at incorrect

temperatures or pressures.

•

High internal pressure in the column due to improper solvent or sample

filtra-tion practices causing particulate buildup or precipitation in the

column or end fittings.

Item

P/N

Quantity

Pico•Tag Reagent Kit

88123

1

Phenylisothiocyanate (PITC)

88120

1

Triethylamine (TEA)

88121

1

Protein Hydrolyzate Standards

88122

1

3.9 mm Filter Replacement Kit

84095

1

Filter Insert Assembly (only)*

84056

2

Retainers (only)*

84057

2