Care and use manual – Waters Sep-Pak DNPH-Silica Cartridges User Manual

Page 3

[ Care and Use ManUal ]

Waters Sep-Pak DNPH-Silica Cartridge

3

The volume of air passed through the cartridge must be large

enough for the quantity of DNPH derivative formed to be several

times greater than the background level (Table 2). The United

States Environmental Protection Agency (US EPA) recommends

that this level be at least 10 times of that of the background

3

.

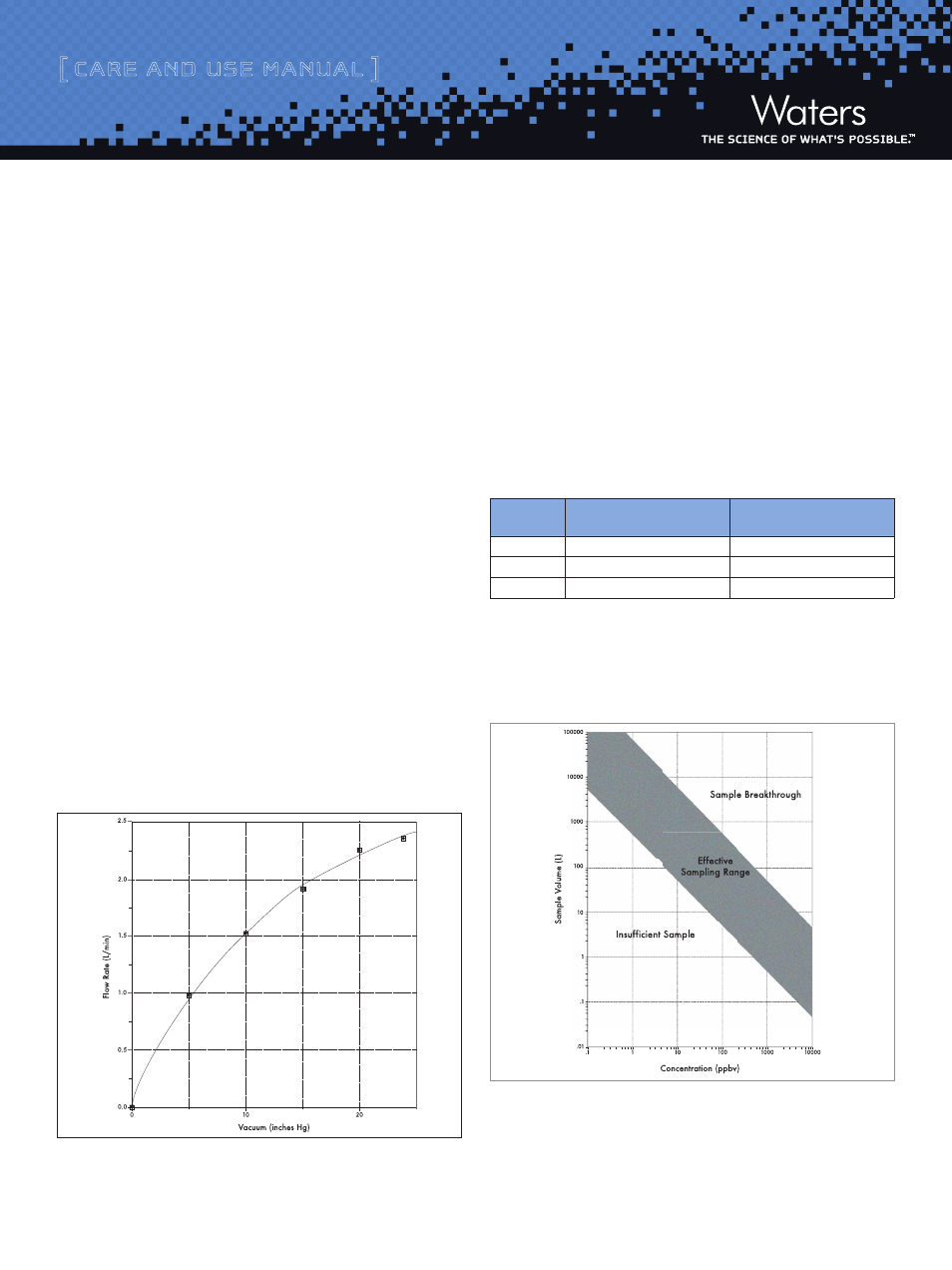

Figure 4 shows the ranges of sample volumes to use as a function

of expected concentration. If you can not predict the concentration

of total carbonyl compounds in a sample, follow the procedure in

Appendix C, Measuring Sample Breakthrough.

Table 2: Background Levels of DNPH Derivatives

* Individually, as acetone-DNPH, determined using a gradient

from 70/25/5 water/acetonitrile/tetrahydrofuran to 40/60 water/

acetonitrile. Other conditions are as in Section III, d.

Figure 4: Range of Sample Volumes vs. Expected Concentration

Caution: Ozone (usually present in urban air) degrades the hydrazone

derivatives

4

. Place an Ozone Scrubber Cartridge (Waters Part

number: WAT054420) on the inlet of the Sep-Pak DNPH-Silica

cartridge.

Notice: Do not use Sep-Pak DNPH-Silica cartridges to process liquid

samples.

To collect the sample:

1. Take the cartridge from its pouch. Remove and save the end cap

and plug.

2. Connect the cartridge to a pump with flexible plastic tubing.

The cartridge is bidirectional (flow can be in either direction).

Figure 3 shows the flow rate through a cartridge versus applied

vacuum.

3. Draw the sample through the cartridge. Record the flow rate and

collection time.

4. Reseal the cartridge with its end cap and plug.

5. Store the cartridge in the provided pouch with appropriate

identification. If possible, seal the pouch using a heat sealer,

or store the cartridge in a glass container with a Teflon

®

-lined

cap. Keep the samples cool (<4 °C). Elute the cartridge within

two weeks.

Figure 3: Flow Rate versus Applied Vacuum

Compound

µg DNPH Derivative per Cartridge

µg as Carbonyl Compound per

Cartridge

Formaldehyde

<1.0

<0.15

Acetone

<2.0

<0.50

Others*

<0.75

-