Care and use manual – Waters Sep-Pak Cartridges and Plates User Manual

Page 4

[ Care and Use ManUal ]

Sep-Pak Cartridges and Plates

4

5. Elution Step

Once the interferences are washed off the cartridge, a strong

solvent is introduced to elute the analytes of interest. The volume

and flow rate of the eluting solvents should be precisely controlled as

in the load step to ensure reproducible results.

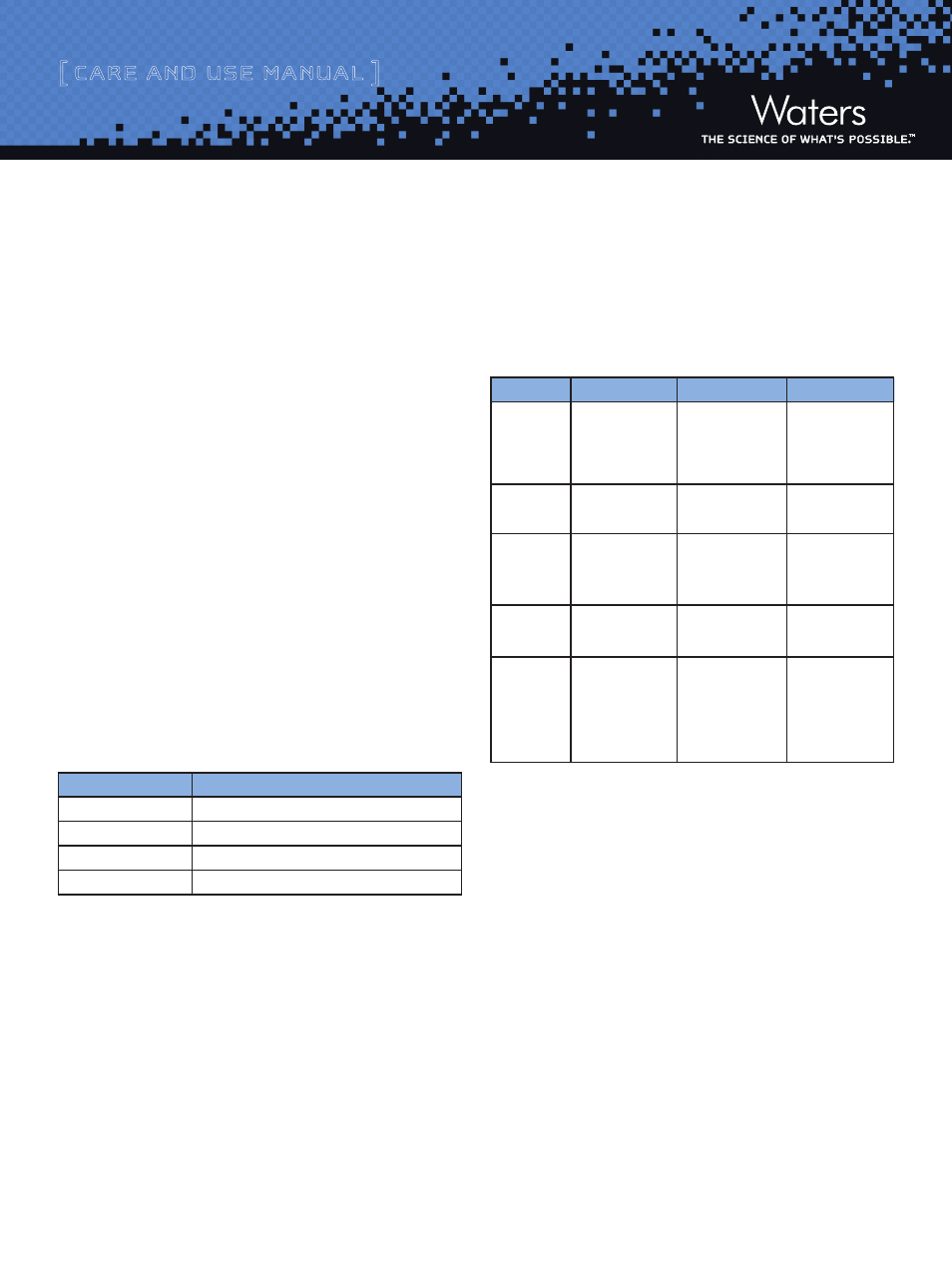

Table 2. Guidelines on the various types of separation mechanisms

V. storAGe And dIsPosAL oF used CArtrIdGes

Cartridges stored in their original sealed pouch remain stable for long

periods. To store unused cartridges in opened pouches, squeeze the air out

of the pouch, fold over the open end of the pouch twice, seal with tape, and

store in a desiccator.

Dispose of used cartridges safely in accordance with applicable government

or local regulations.

3. Load Step

When the analytes of interest are not retained by the sorbent, this is

called analyte breakthrough. For some methods, such as pass-through

cleanup, analyte breakthrough is desirable and is maximized for

those specific methods. However, in all other cases, analyte break-

through is unwanted and contributes to poor recovery and method

reproducibility. Breakthrough occurs when:

• There is too high an organic concentration in the load

solution for very polar analytes. Dilute sample at least 1:1

with water or buffer prior to loading.

• The analytes are bound to proteins, they may pass through

the sorbent. Ensure that analytes are not bound to proteins

by acidifying or basifying the sample.

• Sorbent is overloaded by the matrix component.

Therefore, it is important to choose the correct sorbent

mass (see Table 1).

• The flow rate of the load step is too fast. There is not

enough contact time between the analytes and the sorbent.

Look at the drops and adjust the vacuum so that you see

discrete droplets, not a stream of liquid.

Table 1. Choice of cartridges based on sample size

* LP=large particules (60 µm)

4. Wash Step

The wash steps are designed to remove unwanted matrix components

that remain from the loading step. The ideal wash solvent removes

only the matrix while keeping the analytes bound to the sorbent. For

complex samples this is impossible, so the wash steps are optimized

using pH, solvent strength, and solvent polarity to remove as much

matrix as possible while maintaining acceptable analyte recovery.

Sample Size

Cartridge

1 - 10 mL

1 cc/30 mg or 3 cc/60 mg

10 - 100 mL

3 cc/60 mg or 6 cc/200 mg

100 - 500 mL

6 cc/200 mg or 6 cc/500 mg (LP*)

500 - 1000 mL

6 cc/500 mg (LP) or 12 cc/1 g (LP*)

Reversed Phase

Normal Phase

Ion Exchange

Analyte

Low to

moderate

polarity/

hydrophobic

Moderate to

highly polar/

uncharged

Charged

or ionized

Matrix

Aqueous

Non-polar

organic solvent

Aqueous/low

ionic strength

Condition/

Equilibrate

1. Solvate polar

organic

2. Water

Non-polar

organic

Low ionic

strength buffer

Wash

Aqueous/buffer Non-polar

Low ionic

strength buffer

Elution

Steps

Increase polar

organic content

in steps

Increase

moderate to

high polarity

organic content

in steps

Stronger

buffers–ionic

strength or pH

to neutralize

the charge