Care and use manual – Waters Porapak Gas Chromatography Column Packing Materials User Manual

Page 2

[ Care and Use ManUal ]

Waters PoraPak Gas Chromatography Column Packing Materials

2

II. CoLuMn PACKInG teCHnIQues

Porapak packing materials are rigid, cross-linked polymers which

may be packed into gas chromatography columns using the same

basic technique as used with conventional packing materials.

Since the particles do not crush or fracture easily they may be placed

in the column by using a vacuum to pull the particles into the column

while vibrating the column to cause the particles to settle in a tightly

packed bed. If the columns are packed in this manner, plate counts of

1200 to 2200 plates per meter may be obtained.

NOTE: Porapak packing material can, under certain conditions, pick up a surface

charge during shipping. This may make the packing appear wet and agglomer-

ated when the container is opened for the first time. The material is in fact quite

dry and clean. The surface charge should have no affect on your analysis or

present column packing method.

III. PreCAutIons In use

Porapak porous polymer beads should not be exposed to

temperatures above 250 °C since thermal degradation will occur

above this temperature. The upper temperature limit (in an oxygen-

free atmosphere) for types N and T is 190 °C.

The gas chromatograph used with a porous polymer bead column

must have low adsorption and reaction with the material being

analyzed. If the instrument has adsorption characteristics, this

will cause spreading or tailing, particularly of water or other polar

compounds.

IV. Inst ruMent resPonse

The response of the gas chromatograph can be tested prior to

installing the column simply by using a short unfilled column. Dirt,

oil, cold sections, and components with chemical reactivity in the

instrument can contribute to spreading of the peak. In order to get

good results the instrument must be non-reactive, clean, have small

hold-up volume, and be operated at a suitable elevated temperature.

NOTE: Purging is recommended. To purge, place the Porapak column in an oven

at 250 °C (190 °C for type N and T) with a slow flow of N

2

or He carrier gas and

let it remain there for at least two hours. Porapak beads may discolor upon heat-

ing, but this will not affect analysis. It may also be advisable to dry the packing

material in an oven under the initial conditions prior to packing the column.

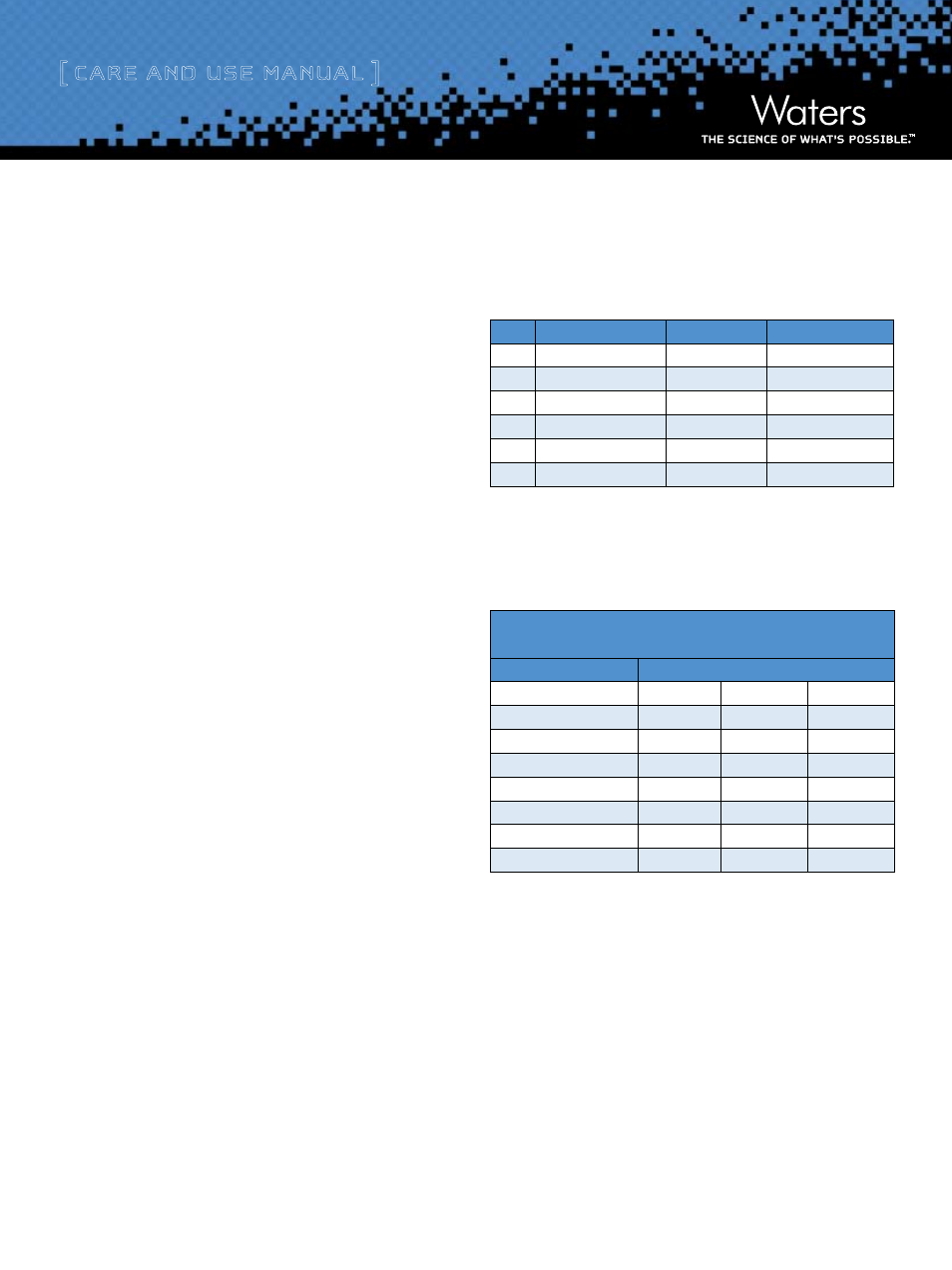

Type

Surface Area (m2/gm)

Density (g/cm3)

Maximum Temp. (°C)

P

100-200

0.27

250

Q

500-600

0.34

250

R

450-600

0.30

250

S

300-450

0.35

250

N

225-350

0.38

190

T

250-350

0.43

190

Table 1: Typical Properties for Porapak Porous Polymers

V. orderInG InForMAtIon

Particle Size (Mesh)

50-80

80-100

100-120

Porapak Porous Packings

Part Number

N

WAT027047

WAT027048

WAT027049

P

WAT027053

WAT027054

WAT027055

Q

WAT027059

WAT027060

WAT027061

R

WAT027065

WAT027066

WAT027067

S

WAT027071

WAT027072

WAT027073

T

WAT027077

WAT027078

WAT027079

PS

WAT027083

WAT027084

WAT027085

QS

WAT027089

WAT027090

WAT027091

Table 2: Ordering Information