Care and use manual – Waters Protein-Pak Epoxy-Activated Affinity Products User Manual

Page 3

[ Care and Use ManUal ]

Protein-Pak Epoxy-Activated Affinity

3

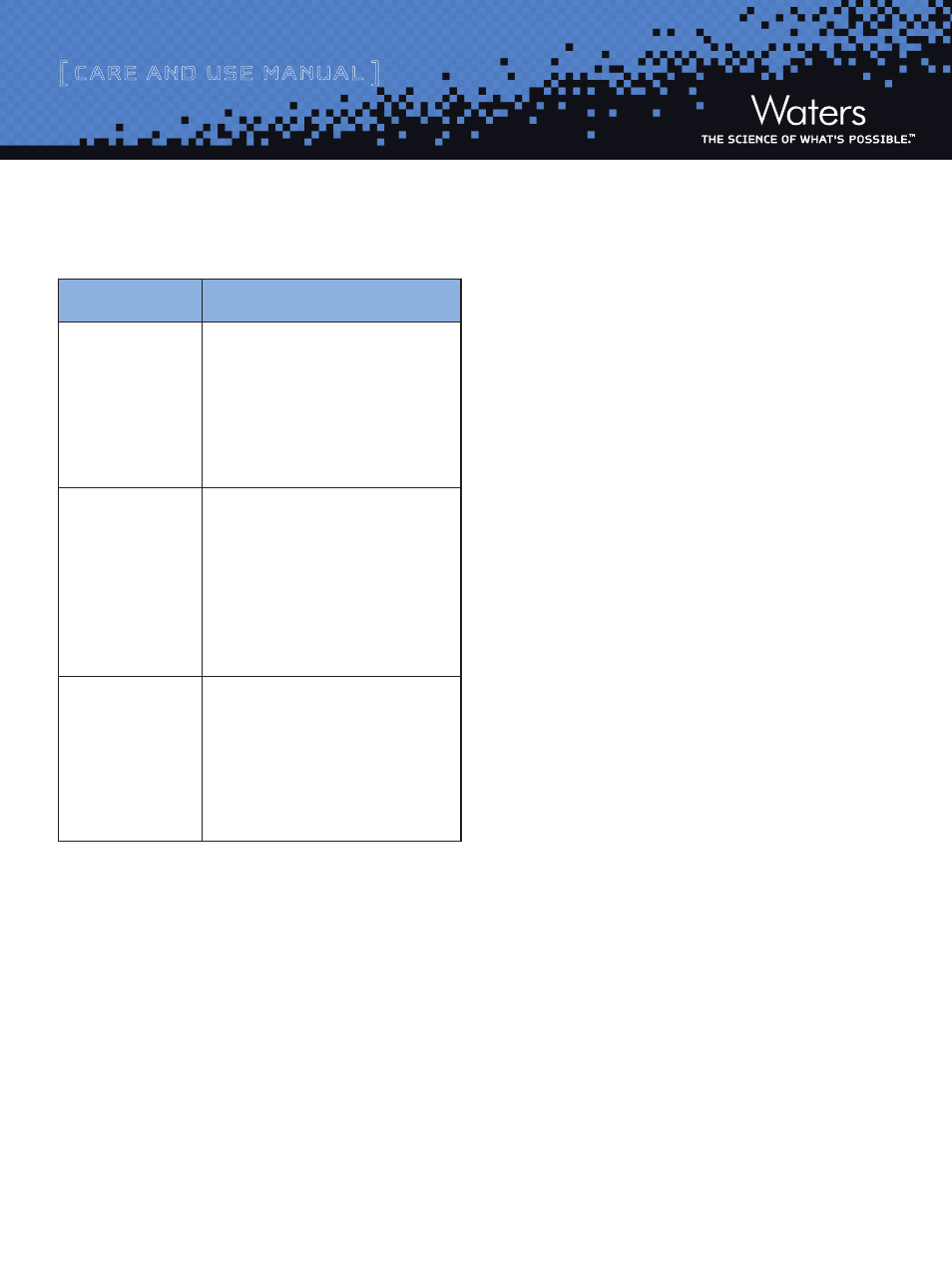

Table 1: Guidelines for Coupling to an Epoxy-Activated Packing

Material

* For insoluble or partially soluble ligands, an organic solvent may be

added to any of the above buffers.

To couple the ligand

1. Weigh out the amount of material required to pack the column.

The bulk density of the material is about 0.5 g/mL, so about

0.5 grams of material is required per mL of column volume.

2. Place the material in a tube or bottle with a screw cap that fits

securely. A screw cap is required so that no liquid is lost when

the container is rotated on a laboratory wheel or shaken.

3. Add three parts coupling buffer or solvent to one part packing

material, slurry or suspend, and rotate on a laboratory wheel or

shaker for 5 minutes. Let the material settle.

4. Decant the supernatant liquid and then wash the packing mate-

rial three times with fresh coupling buffer or solvent, using part

buffer or solvent, using three parts buffer or solvent to one part

packing material.

5. Dissolve the ligand in the coupling buffer or solvent in a test

tube. Keep the concentration of the ligand solution as high as

possible.

Note: During the coupling step, the final volume of buffer mass of

affinity material should be 3 to 4 mL solution per gram of material.

6. Following the guidelines shown in Table 1, mix the ligand

solution with the material using a rotating wheel. Alternatively,

when carrying out couplings at temperature above room tem-

perature, use a shaker in a water bath. Do not use a magnetic

stirrer because the silica beads may fragment or the ligand may

be damaged.

c. Blocking Procedure

1. The blocking solution may be added after the coupling solution

is removed or added directly to the reaction mixture. Block

unreacted epoxy groups with a final concentration of 1 M

ethanolamine solution at pH 9.5 in coupling buffer (2 mL/g) by

rotating for 18 to 24 hours at 4 °C.

2. Filter off the coupling/blocking supernatant using a coarse-

porosity, sinterd glass funnel. Save the solution to quantitate

the amount of unbound ligand.

d. Washing Procedure

Perform the following sequence of washes to remove excess ligand

and blocking solution. Use 6 mL of solution per gram of packing

material for each wash.

1. Coupling buffer or solvent (one wash)

Note: If coupling is performed in an organic solvent, initial washes

should be of an increasing polarity; for example toluene, acetone, and

then water.

2. 1 M NaCl solution (four washes).

3. Use one of the following buffers (one wash):

Loading buffer based on the application

Storage buffer (see Section II, e below)

Functional Group on the

Ligand

Coupling Conditions

Primary, secondary, and

aromatic amines and

sulfhydryl

Any of the following at 20 °C to 55 °C, 17- 24

hours:

• 0.1-1.0M phosphate pH 6-7.5

• 0.1 M borate, pH 8- 9.5

• Organic solvents

Hydroxyl

Any of of the following at 4 °C-45 °C, 17-72

hours:

• 0.1-1.0M phosphate pH 3-6.5

• Organic solvents such as dimethyl sulfoxide,

dimethyl formamide, acetonitrile

• Alkali pH 11-13 (no more than 18 hours)

Proteins including

enzymes and antibodies

Any of of the following at 4 °C-45 °C, 24-72

hours:

• 0.1-1.0M phosphate pH 3-7.5

• 0.1-0.5M carbonate or borate, pH ≥

• 8.0 with or without 0.05 to 1.0 M NaCl