Care and use manual – Waters Protein-Pak Epoxy-Activated Affinity Products User Manual

Page 2

[ Care and Use ManUal ]

Protein-Pak Epoxy-Activated Affinity

2

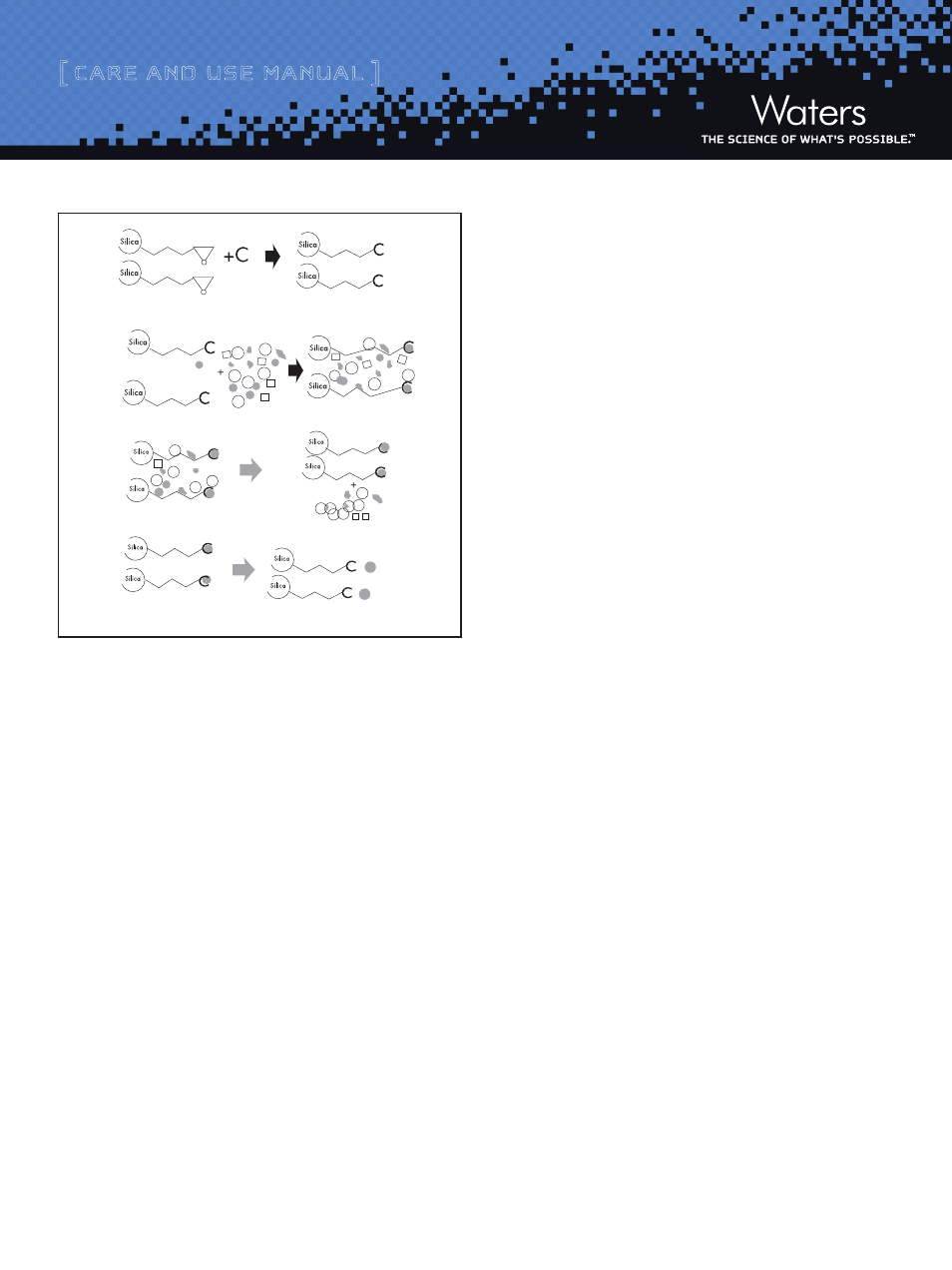

Figure 1: Epoxy-Activated Affinity Process

c. Description of the Products

Epoxy-activated packings are available in bulk and in Micro-Column

configurations. Bulk material, the Micro-Column, and conditions for

coupling the ligand are described below.

Bulk Material

The bulk packing material is available in 25 and 100 gram amounts.

Larger quantities are available on request. The material is shipped as

a dry white powder and should be stored dry at 4 °C. The bulk density

of the material is about 0.5 g/mL, so about 0.5 grams of material

is required per mL of column volume.The epoxide content is greater

than 100 μmoles/gram.

Micro-Column

The Micro-Column contains 0.5 mL of Protein-Pak Epoxy-Activated

Affiinity packing with 50 to 100 μmoles of available activated sites.

The Micro-Column volume is 3 mL, resulting in a 2.5 mL reservoir.

The outlet has a filter. The top of the bed does not have a filter. The

Micro-Column housing is polypropylene which is stable to all normal

coupling temperatures (4 °C to 45 °C) and pHs (pH 2 to 9.5).

Ligand Coupling

Couple ligands to the epoxy-activated packing by following the

procedures for Coupling Conditions covered in Section II. Unreacted

epoxy groups on the coupled material may interfere with subsequent

use in a chromatographic separation. After the affinity ligand is

immobilized, the remaining epoxy groups can be blocked by reac-

tion with amino compounds of low molecular weight (for example,

glycine, tris buffer, or ethanolamine). The derivatized material is

ideal for use in either batch processes or in packing columns.

II. use of epoxy-ACtIvAted AffInIty pACkIngs

a. Coupling Buffers

Prepare buffers and solvents using the following general guidelines.

– Carbonate, borate, and phosphate buffers are preferred.

Sodium chloride or other non-nucleophillic salts may be

added to achieve a desired ionic strength.

– Do not carry out the coupling in tris, glycerine or other

nucleophillic buffers. These buffers will react with the epoxy

groups.

b. Coupling Conditions

This section outlines general procedures for coupling a ligand to the

material. Table 1 lists general conditions for the covalent binding

of ligands based on different functional groups. The temperature

limitation of the coupling reaction depends on the stability of the

ligrand; generally ligands can be coupled to the support between

4 °C and 55 °C.

CAUTION: Bonded phases on silica are susceptible to hydrolysis at

extreme pHs. When using the material at pH 2 or pH > 9.5, bonded

phase hydrolysis may occur and result in non-specific chromatographic

effects.

Spacer Arm

Epoxide

Ligand

Step 1: Ligand Coupling

Step 4: Washing Out Impurities

Step 2: Loading Sample Mixture

Step 3: Adsorbing Target Material

Step 5: Eluting Target Material

Step 6: Re-Equilibrate and go to Step 2