Care and use manual – Waters Protein-Pak PW Ion-Exchange Column User Manual

Page 4

[ Care and Use ManUal ]

Protein-Pak PW Ion-Exchange Columns

4

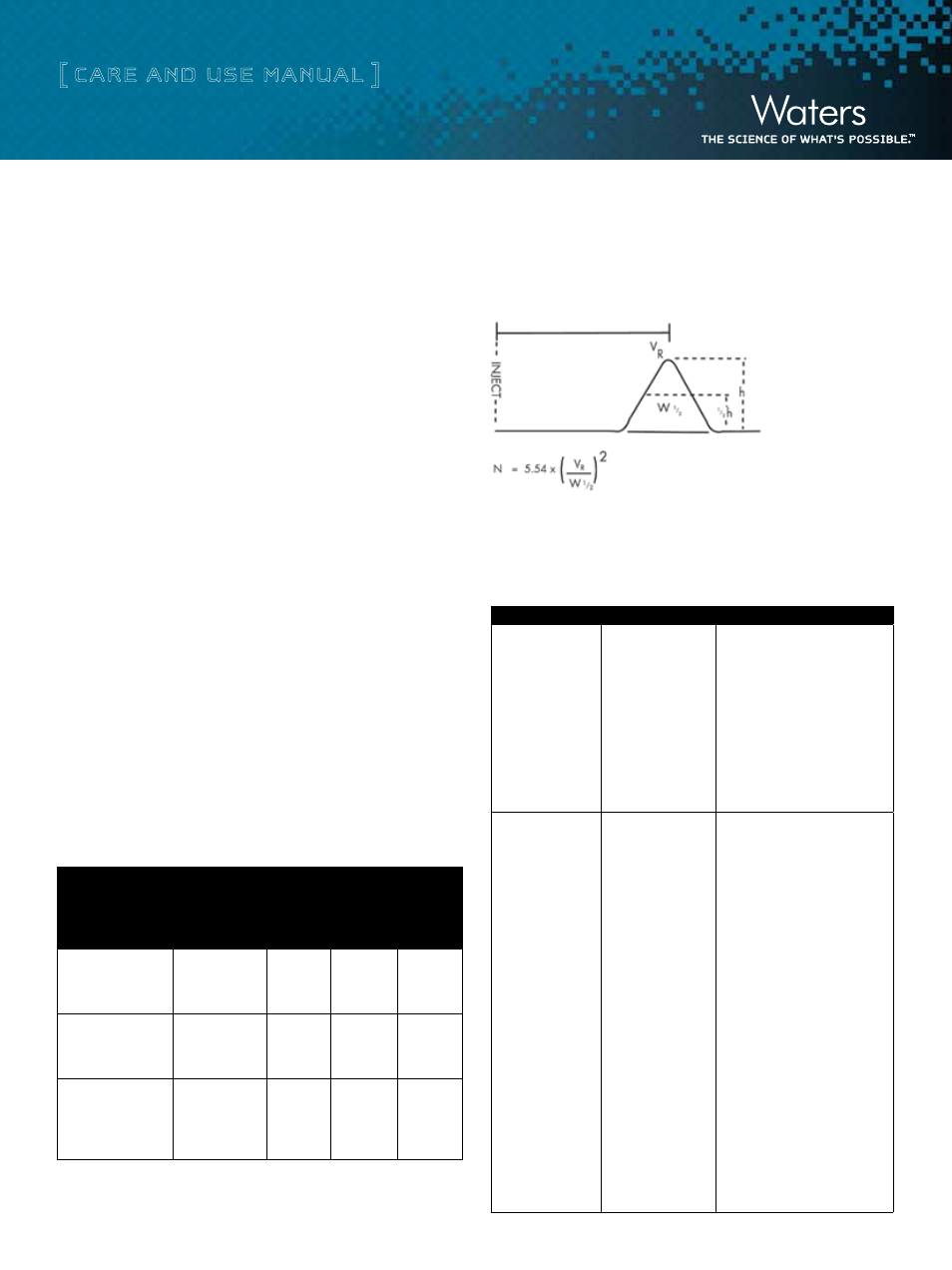

a. Column Efficency

Waters Corporation measures the efficiency of the Protein-Pak ion-

exchange columns using the 1/2 peak height method. Plate count, as an

expression of efficiency, is determined as shown in the following diagram .

v. TROUbleshOOTINg

Figure 2: Typical Column Problems and Solutions

Problem

Cause

Solution

Excess pressure

buildup

• Filters

plugged with

Particulates

• Sample precipi-

tates on column

(sample not

soluble in mobile

phase)

• Clean filters in an ultrasonic

bath or replace. Always filter

solvents and samples

• Slowly purge with a strong

eluent appropriate to dis-

solve the contaminate.

Loss of resolution,

broad peaks,

low plate counts

• Contaminated

column,

insufficient

equilibration

• Filters partially

plugged

• Column collapse

and void formation

• To wash or regenerate

columns, 0.1-0.2 NaOH

solutions are very effective.

Usually columns can be

regenerated by making

several 1-2 mL injections of

0.1-0.2 N NaOH. If this does

not improve column perfor-

mance, wash column with

several 1-2 mL injections

of 20-40% acetic acid.

• Since this may occur during

the first two weeks of use,

Waters Corporation will

replace any column with

this defect.

• Replace or clean inlet and

outlet filters.

N= Column Efficiency (plates)

V

r

= Volume peak apex (μL)

W 1/2= Volume of peak at

1/2 peak height (μL)

Column Name

Part Number

Mobile

phase

Optimal

Flow

Rate

(mL/min)

Test

Sample

Peak

Protein-Pak DEAE

5PW 7.5 mm x

75 mm

WAT088044

HPLC

grade

water

1

2 μL

acetone

Protein-Pak

SP-5PW

7.5 mm x 75 mm

WAT088043

HPLC

grade

water

1

2 μL

acetone

Protein-Pak

SP-5PW

21.5 mm x

150 mm

WAT010640

HPLC

grade

water

5

10 μL

acetone

d. Storage Consideratons

Store columns in distilled water. If microbial contamination is a

concern, refrigerate at 4-6 °C. DO NOT FREEZE.

DO NOT allow buffers or other potentially harmful materials to

remain in the system overnight when not being used. Run buffers with

a slow flow rate (0.1 mL/min) overnight if necessary.

Return the column to its box with the end caps firmly in place for

storage. Allowing steel columns to dry out can result in poor chro-

matographic performance.

Iv. TesT CONDITIONs

Columns are thoroughly tested in adherence to our specifications. Since

slight variations in your results will occur depending on the equipment used,

test sample makeup, and equipment settings and condition, perform the test

sample run given here for your new column and record the results (retention

time and the settings used) before attempting the first analysis. Use these

results for comparison throughout the life of your column.

Detectors should be run at 254 nm or 280 nm (UV). Otherwise, use instru-

ment settings that produce an acceptable test peak (this may mean using a

lower sensitivity on the UV detectors than normally practiced for a specific

analysis).

Note: Be sure to record results and instrument setting (and configurations) to

allow exact reproduction and comparison in the future.