Care and use manual – Waters Protein-Pak PW Ion-Exchange Column User Manual

Page 2

[ Care and Use ManUal ]

Protein-Pak PW Ion-Exchange Columns

2

II. PRePaRaTION fOR OPeRaTION

a. Steel Column Installation

Remove the end plugs from your column with a 5/16” wrench and save them

for storage when the column is removed from the system. The column outlet

is indicated by an arrow on the label (showing the direction solvent should

flow). Tighten the fittings 1 /4 to 1 /2 turn.

Note: Do not overtighten, this will damage the fitting seat.

A properly prepared and assembled compression fitting in good condition is

all that is required.

Follow the next four steps of this procedure if tubing cutting is required

to connect a new steel column or to improve the end connections on your

existing fittings.

1. Using a file with a cutting edgescribe the circumference of the tubing

at the desired break.

2. Grasp the tubing on both sides of the scribe mark with cloth-covered

pliers (to prevent marring the tube surface) and gently work the tube

back and forth until it separates.

3. File the ends smooth and assemble as shown.

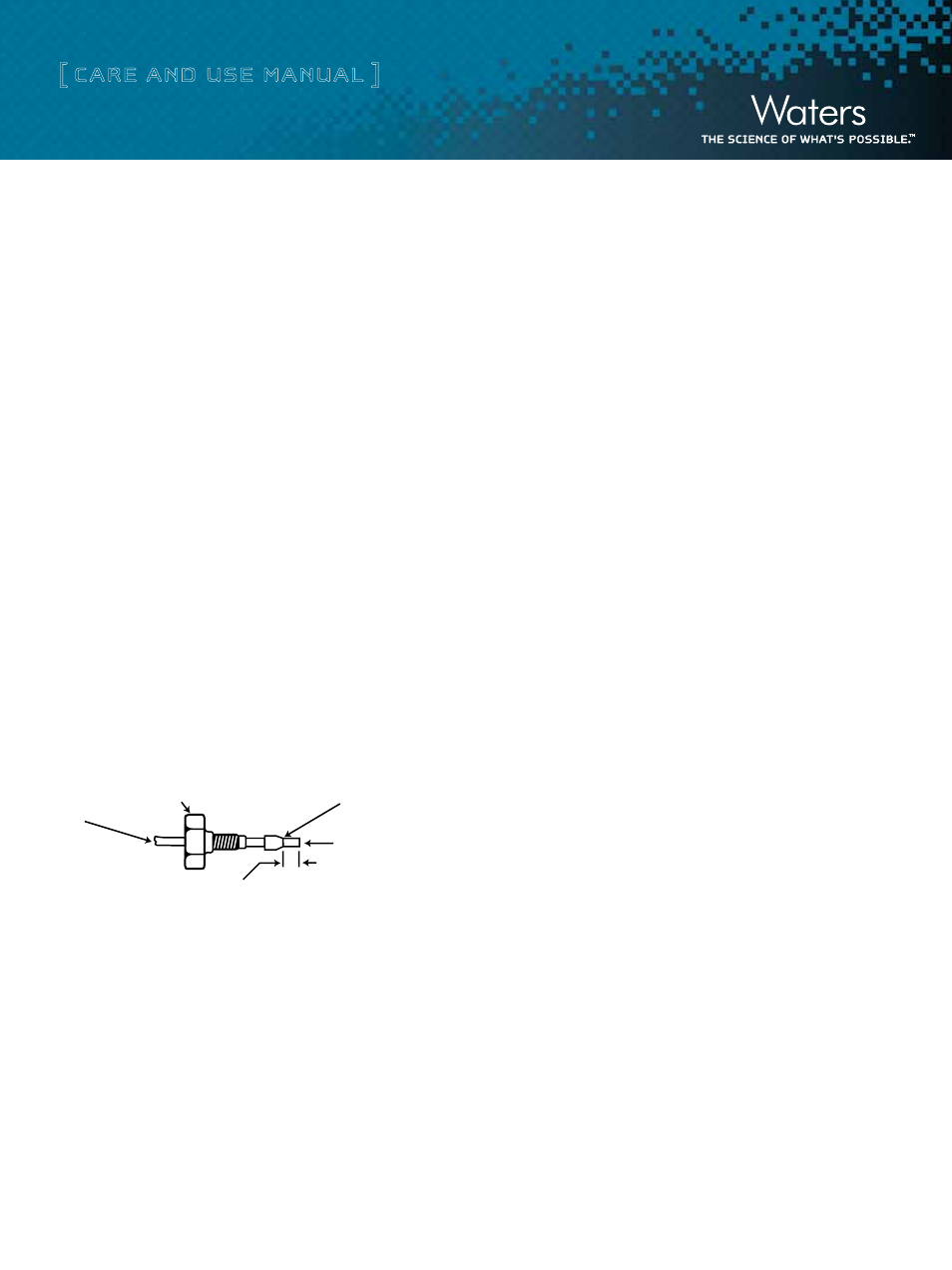

Figure 1: Ferrule and Compression Assembly

Note: Proper positioning of the ferrule in the fitting seat will prevent forma-

tion of unwanted dead volume which could result in sample mixing.

4. Slide the compression fitting, followed by the ferrule (large end of the

taper first) over the tube. Be certain to bottom the tube in the fitting

seat which is used to assure a leak-free connection.

Note: Attach a union in place of the column and flush the lines free of

microparticulate before attaching the column

b. Glass Column Installation

Install the pre-packed Protein-Pak PW series of ion exchange glass

columns on any HPLC or medium-pressure system. Refer to the

appropriate operator’s manual for installation information. Refer to

Table 6 for part numbers and specific adapter information. Install the

columns in a vertical position for optimum performance.

Cautions

•

When using preparative columns (AP-2 and AP-5) at elevated flow

rates, do not exceed the pressure limits of the column. Use a detector

flow cell configuration which will accommodate higher flow rates

without generating excessive backpressure

• Non-metallic fittings should be hand-tightened only. Overtightening

does not improve performance and may damage the threaded parts. If

leakage occurs, check for damage to the threaded parts, ferrules, and

0-rings, or for foreign matter on the sealing surfaces.

• Do not adjust the piston on the column while there is flow through the

column. This could result in damage to the glass column and 0-rings.

See the Waters Advanced Purification Glass Column Care & Use Manual for

details.

c. Solvent Requirements

Protein-Pak DEAE-5PW and SP-5PW are shipped in distilled water. After

running the columns return them to distilled water for overnight storage. The

organic concentration is limited to no more than 20%.

d. Buffers

Protein-Pak columns are stable in normal salt buffer solutions such as

sodium sulfate, ammonium acetate, ammonium formate, phosphate buffers,

tris acetate and acetate buffers. Concentrations in aqueous solutions of less

than 1M are recommended. Maintain buffers used during analysis between

pH 2-12. Buffers containing halide ions for example, sodium chloride can be

used, but care should be taken to thoroughly flush the column with distilled

water after use.

e. Equilibration

A necessary step to successful use of your new column is the initial solva-

tion (or wetting) of the column. Purge the column for 15 minutes at 1 ml/

min with the starting buffer. Equilibration between the eluent (buffer) and

packing is established when a stable baseline can be produced. If your result

is unsatisfactory repeat the equilibration process.

COMPRESSION SCREW OR NUT

TUBE

FERRULE

END MUST BE STRAIGHT

AND SMOOTH TO ACHIEVE

MAXIMUM COLUMN EFFICIENCY

CRTITICAL DISTANCE TO BE DETERMINED BY

EACH APPLICATION (UNION, COLUMN FITTING ETC.)