Care and use manual – Waters Preparative Chromatography Mix Standard User Manual

Page 4

[ CARE AND USE MANUAL ]

Preparative Chromatography Mix

4

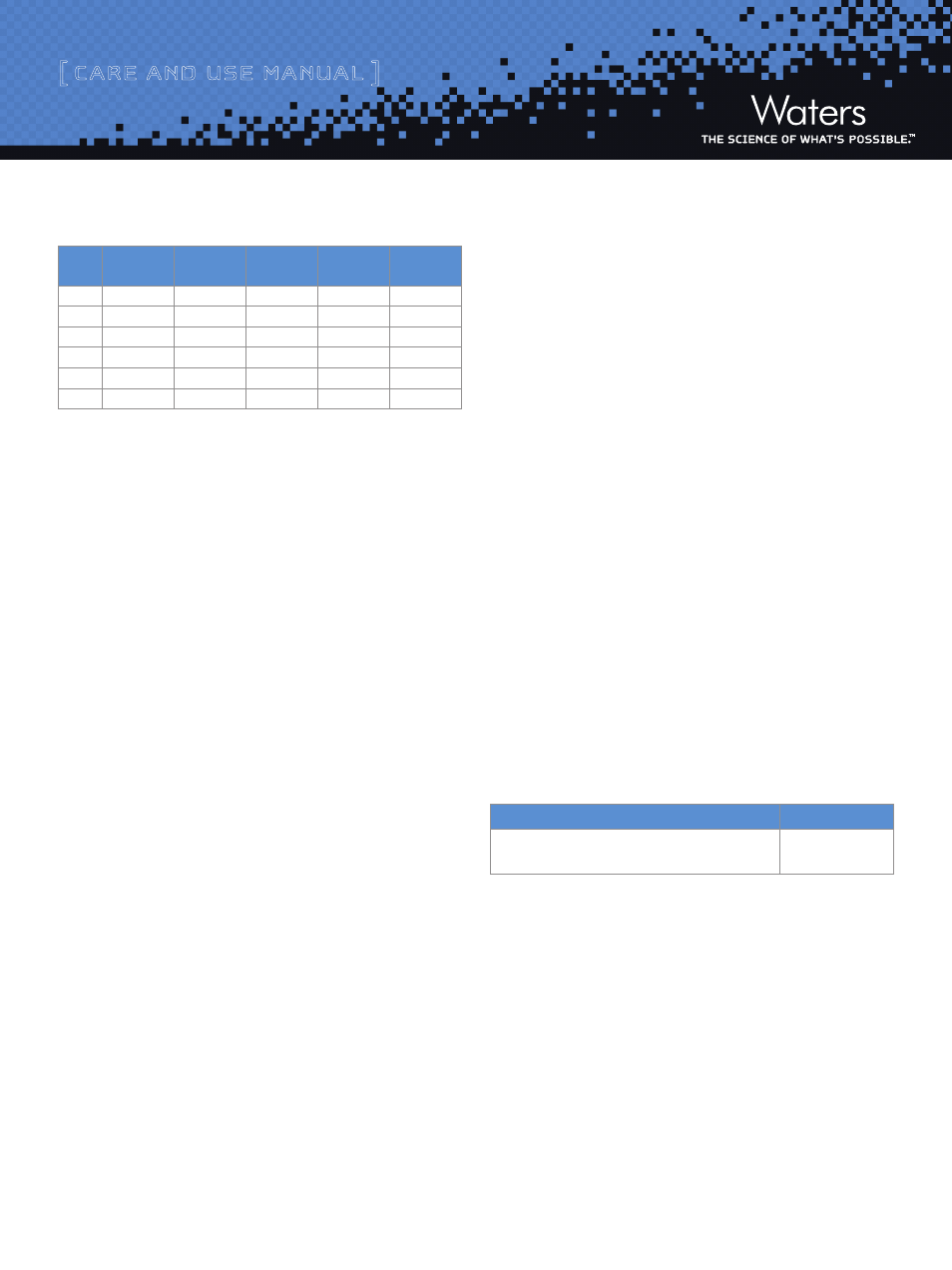

Figure 2: Retention Time Control Chart

The establishment of control limits provides data as to the current

capabilities of the system. Control charting allows the quality

professional to compare instrument performance to the required

method specifications.

The process of continuous quality improvement can also be tracked

using control charts. When improvements are made to a method,

control charts allow you to see that the changes you have made are

effective and having the desired impact. The control chart will also

allow you to track trends over time. By observing the data trending

higher or lower over time, you can take preventative action prior to

having an out of specification result.

Control charting can be employed for each QCRM criteria; peak

retention time, peak area, peak width, and peak resolution. Control

charts allow quality control professionals to establish statistically

significant criteria to monitor and control their HPLC analyses

thereby avoiding criteria that are too stringent or set arbitrarily.

Summary

The use of high quality reference standards specifically designed for

the system analysis, provide a controlled, consistent, and reliable

measure of system performance. Regular use of reference standards

and control charting the data provides improved monitoring of system

performance and system robustness, while at the same time

providing assurance that any results produced are high quality,

reliable, and reproducible.

References

1) Taylor, J.K., “Quality Assurance of Chemical Measurements”, Lewis Publishers, 1987

2) Smith, G.M., “Statistical Process Control and Quality Improvement”, 3rd edition,

Prentice Hall, 1998

3) Ahuja, S. and Dong, M.W., “Handbook of Pharmaceutical Analysis by HPLC”, Elsevier

Inc., 2005

V. TROUBLESHOOTING:

The Preparative Chromatography Standard contains an acidic, basic

and neutral compound. Due to the vastly different properties of

stationary phases, not all compounds will behave similarly on each

column. For instance, basic compounds often have poor peak

shape on reversed-phase columns at neutral pH due to increased

interactions between the charged bases and silanols on the surface

of the stationary phase. For this reason, it is very important to

benchmark the performance of the Preparative Chromatography

Standard on a new column and functioning system. This will help

to identify whether poor peak shape issues are due to compound

interactions on the column, or failing column/system performance.

Failure to meet QCRM criteria will result in the need to troubleshoot

the system. Some chromatographic issues may be easily resolved,

for instance, a missing peak may simply be due to co-elution of

two peaks. However, most issues such as poor peaks shape, tailing

peaks, retention time shifts and poor peak response, to name a few,

may be due to a variety of causes that can be difficult to pinpoint.

For a detailed and comprehensive guide to troubleshooting, please

refer to the HPLC Troubleshooting Guide (WA20769) on the

Waters website.

VI. ORDERING INFORMATION

Description

Part Number

Preparative/Purification Chromatography

Mix Standard

186006703

Thank you for choosing a QCRM from Waters. The standards are

manufactured in our ISO 9001 ISO 17025 facility. Each standard

is manufactured to ensure optimal reproducibility from lot to lot. A

Waters QCRM can be depended on for its’ accuracy. This removes

one variable from your system variability and provides you the most

dependable starting point for your testing.

If the QCRM box shows significant damage, notify the carrier and

your supplier at once and retain evidence of shipping damage so that

a claim can be made.

Time

(min)

Flow

(mL/min)

%A

%B

Curve

1

Initial

25.00

95.0

5.0

Initial

2

0.10

25.00

95.0

5.0

6

3

6.10

25.00

5.0

95.0

6

4

7.10

25.00

5.0

95.0

6

5

7.20

25.00

95.0

5.0

6

6

10.10

25.00

95.0

5.0

6

A = 0.1% TFA in water

B = 0.1% TFA in acentonitrile