Care and use manual, Iv. qcrm testing – Waters Preparative Chromatography Mix Standard User Manual

Page 3

[ CARE AND USE MANUAL ]

Preparative Chromatography Mix

3

IV. QCRM TESTING

The use of reference standards for QCRM testing should allow the

analyst to track important instrument analytical parameters such as

peak width, peak area, retention time, and peak resolution. Each of

these important parameters can be tracked and evaluated using control

charts. The use of a high quality reference standard allows the analyst

to reliably measure and track these parameters.

QCRM testing should be performed on a regular basis for each

instrument/analyst combination or instrument per test method. The

data should be collected and entered into a control chart allowing

the analyst to evaluate the system performance over time. The use of

performance control charts has been a staple of analytical chemistry

quality control. The most common form of the control charting is to

track the analytical results and statistically analyze the data to a 99%

(3 standard deviations) or 95% confidence interval (2 standard

deviations) confidence interval around the mean of the data to

establish upper control limits (UCL) and lower control limits (LCL).

The initial criteria to establish a mean, standard deviation and

control limits involves analyzing a reference material a minimum

of 7 times to establish an initial estimate of precision and bias. This

provides the analyst with sufficient data to be statistically valid. The

analyses should be carried over the course of several days to provide

a more realistic view of the system variability. The frequency

of analyzing system performance will be dependent on the stability

of the analysis and the analytes. QCRM should always be evaluated

after maintenance has been performed, or when changes to the

system or analytical procedure have been made.

The example in Table 1 uses retention time monitoring to establish

a set of control limits for the purpose of monitoring on-going

system performance.

Table 1: Reference Standard Retention Time Data Example

Analysis Peak

Retention Time (mins)

1

7.10

2

7.11

3

7.12

4

7.09

5

7.08

6

7.10

7

7.11

8

7.13

9

7.10

10

7.11

Mean 7.11

Standard Deviation 0.0136

LCL 7.08

UCL 7.13

The standard reference material was analyzed 10 times yielding

the above retention times. The mean retention time and standard

deviation were calculated and from this the UCL and LCL limits

were determined. The control limits represent a 95% confidence

interval (2 standard deviations) for the data. The control chart

in Figure 2 was then produced to establish that the instrument

retention times are in control.

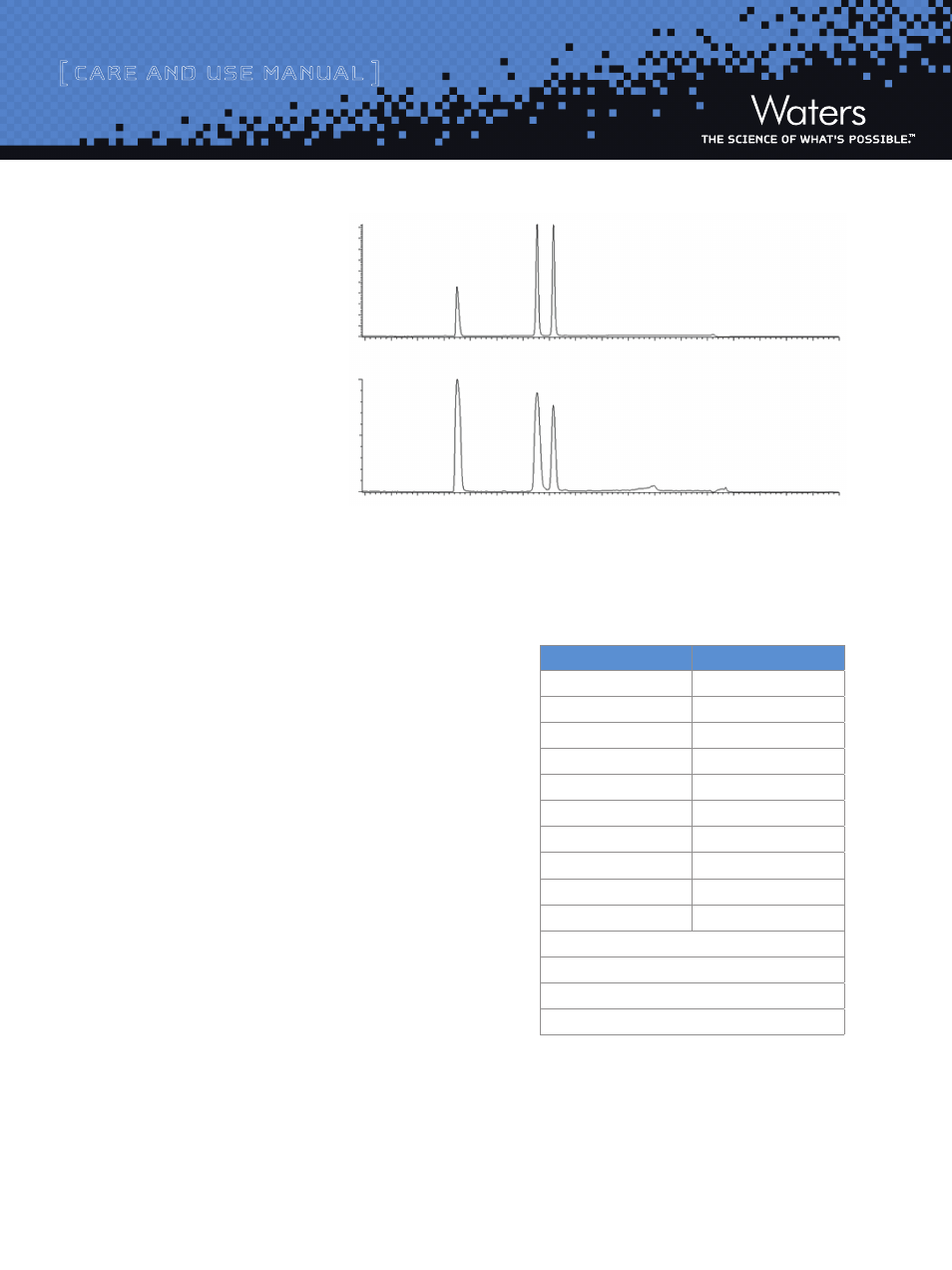

Figure 2 shows an example of the

chromatography obtained for the

preparative mix via UV and MS

when the method in Figure 1 is

using an XSelect

™

CSH

C

18

, 5 µm,

19 x 50 mm.

1. Diphenhydramine

2. Flavone

3. Diclofenac

220 nm

TIC; ES +

1

2

3

1

-1

0.0

2.0e-1

4.0e-1

6.0e-1

8.0e-1

AU

%

99

2

3

4

5

6

7

8

9

10 min

1

2

3

4

5

6

7

8

9

10 min