Care and use manual – Waters Protein-Pak Hi Res IEX Columns User Manual

Page 7

7

[ CARE AND USE MANUAL ]

Protein-Pak Hi Res IEX Columns and Standards

made, they likely originate from adsorption to some system

component. In that case follow the instrument manufacturer’s

recommendations. Memory effects as a source of carryover

may be reduced or eliminated in several ways. First, raising the

temperature of the separation reduces the possibility of non-

specific protein adsorption. Second, memory effects may be

more pronounced with steep gradients. Keep the gradient slope

at 10 column volumes or greater. Third, memory effects may

be exacerbated by high flow rates. Reduce the flow rate by one

half while doubling the gradient time to maintain a constant

slope. Finally, apparent memory effects may actually reflect

the solubility of the protein in the mobile phase. Reducing the

amount injected may eliminate the effect.

Note: Useful general information on column troubleshooting

problems may be found in HPLC Columns Theory, Technology

and Practice, U.D. Neue, (Wiley-VCH, 1997), the Waters HPLC

Troubleshooting Guide (Literature code # 720000181EN) or visit

the Waters Corporation website for information on seminars

www.waters.com).

VI. COLUMN CLEANING, REGENERATION

AND STORAGE

a. Cleaning and Regeneration

Changes in peak shape, peak splitting, shoulders on the peak,

shifts in retention, change in resolution, carryover, ghost peaks,

or increasing backpressure may indicate contamination of the

column. Choose a cleaning option that may be expected to

dissolve the suspected contaminant.

1. It may be useful to conduct cleaning procedures at one-half the

flow rate typically used with that column. In this way the

possibility of high pressure events is reduced.

2. Several different cleaning solutions may be injected to

strip strongly adsorbed material or particulates from the

column. Make the largest injection possible with the system

configuration. With such strong cleaning solutions, it is best to

disconnect the detector from the column and to direct the flow

to waste.

a. 0.1mol/L NaOH, or

b. 20 ~ 40% acetic acid, or

c. Solution containing aqueous organic solvent such as

methanol or acetonitrile

d. Solution containing a solubilizer such as urea and

non-ionic surfactants

3. Flow reversal or back flushing is often suggested as part of a

cleaning procedure. This should be reserved as a last resort.

It may further damage the column or provide a short-lived

improvement in performance.

b. Storage

For overnight storage, the column can remain in the IEX separation

eluent while maintaining a low flow rate (e.g., 0.1 mL/min). For

long-term storage, replace the eluent at the suggested flow rate

shown below with filtered, high purity water containing 0.05%

sodium azide that will inhibit undesired microbial growth.

<0.25 mL/min for Protein-Pak Hi Res Q, 5 µm columns

<0.5 mL/min for Protein-Pak Hi Res CM and SP, 7 µm columns

Completely seal column to avoid evaporation and drying of the bed.

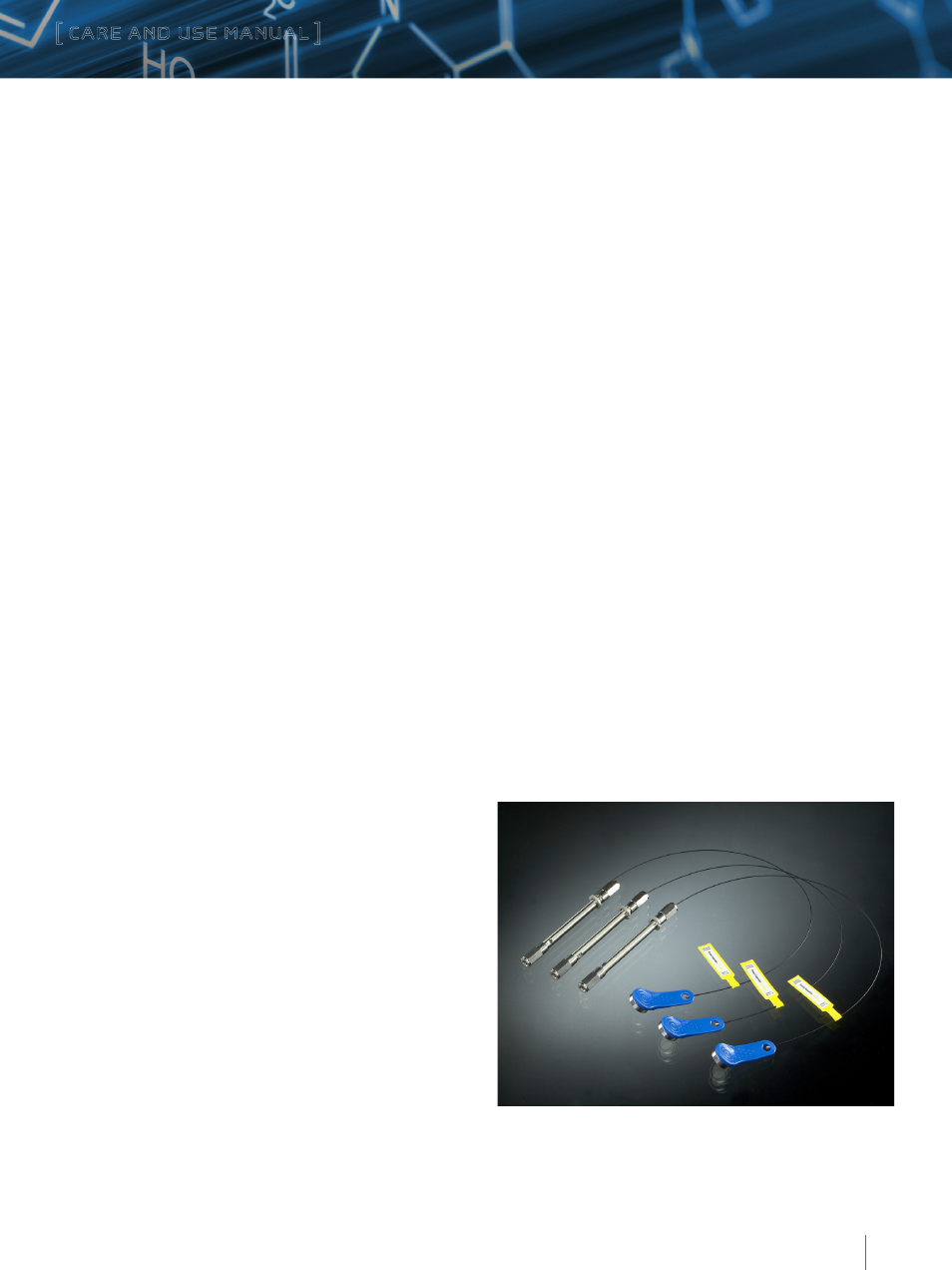

VII. INT RODUCING ECORD INT ELLIGENT

CHIP T ECHNOLOGY

a. Introduction

The eCord intelligent chip is a new technology that will provide

the history of a column’s maximum backpressure, maximum

temperature and the number of injections performed throughout its

lifetime. The eCord will be permanently attached to the column to

assure that the column’s performance history is maintained in the

event that the column is moved from one instrument to another.

Figure D. Waters eCord Intelligent Chip