Care and use manual – Waters Enzymate BEH Pepsin Columns User Manual

Page 3

3

[ CARE AND USE MANUAL ]

Enzymate BEH Pepsin Column

b. Column Installation and Equilibration

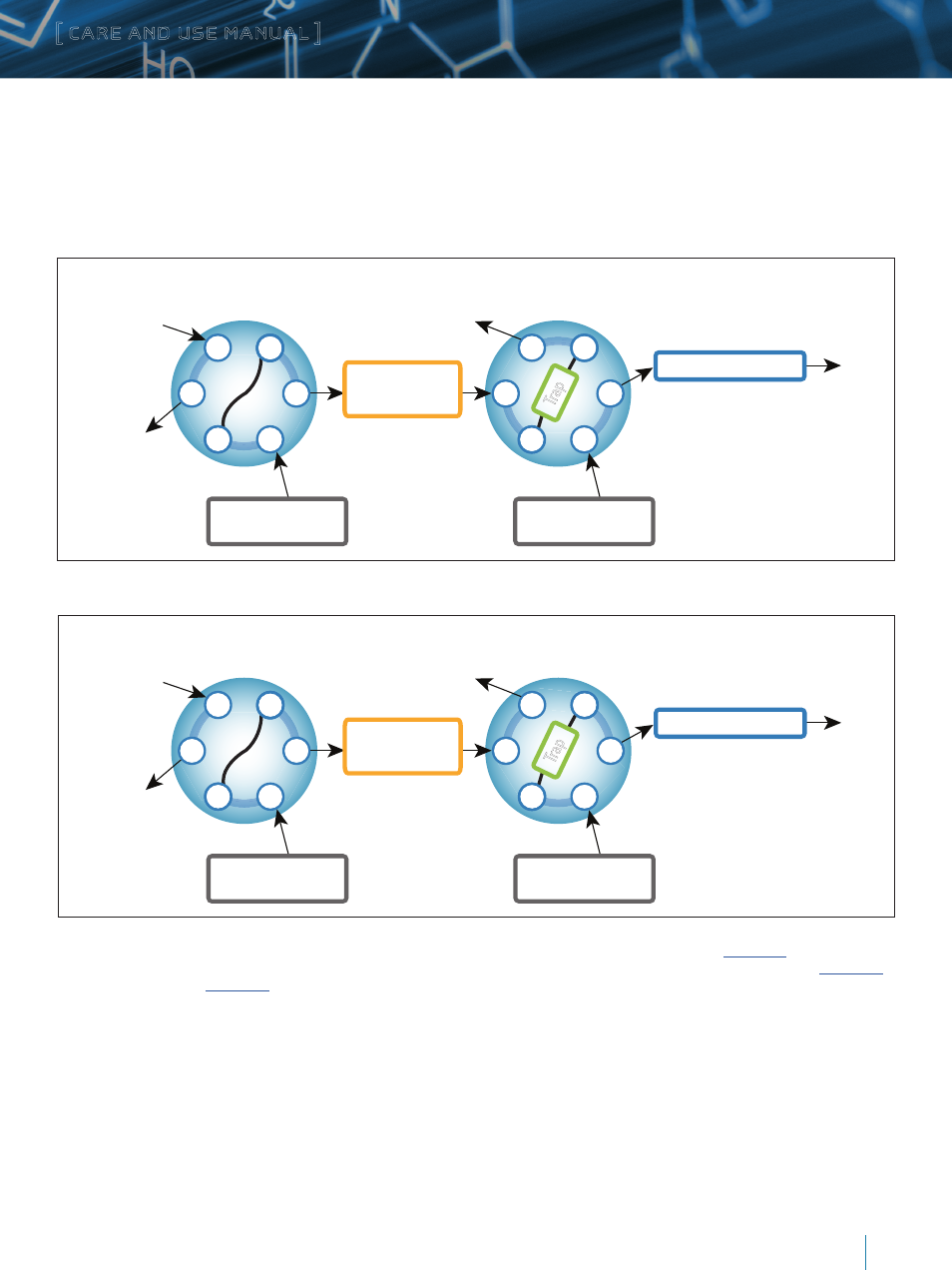

Install the Enzymate BEH Pepsin Column in the temperature controlled compartment located on the left side of the HDX Manager

(maintained between 10 and 20 °C). Connect it between port 6 of the Injection Valve and port 3 of the Trap Valve as indicated in Figures 2a

and 2b.

1. Set the temperature of the Enzymate BEH Pepsin Column to between 10–20 °C. Higher temperatures aid digestion and lower

temperatures minimize back-exchange.

2. Equilibrate the Enzymate BEH Pepsin Column using 0.1% formic acid in water, pH 2.5 for at least twenty minutes (20 column volumes) at

a flow rate of 100 μL/min before performing protein digestions.

1

2

3

4

6

5

2

3

4

6

5

1

Binary Solvent

Manager (BSM)

Auxiliary Solvent

Manager (ASM)

Waste

Waste

Sample

Trap Valve

Injection Valve

Tra

p

Enzymate BEH

Pepsin Column

ACQUITY UPLC

®

Column

To MS

1

2

3

4

6

5

2

3

4

6

5

ACQUITY UPLC

®

Column

1

Binary Solvent

Manager (BSM)

Auxiliary Solvent

Manager (ASM)

Waste

Waste

Sample

Trap Valve

Injection Valve

To MS

Tra

p

Enzymate BEH

Pepsin Column

Figure 2a. Protein digestion in trapping mode (sample already injected and is in loop).

Figure 2b. After proteins are digested on the Enzymate BEH Pepsin Column, the valve is switched and the peptic peptides are separated using reversed-phase UPLC.

The trap column used is a VanGuard 2.1 x 5 mm Pre-Column containing 1.7 μm ACQUITY UPLC BEH C

18

packing material (part number

). The analytical

reversed-phase separation occurs on an ACQUITY UPLC Column containing 1.7 μm ACQUITY UPLC BEH C

18

packing material (1.0 x 100 mm, part number

or 1.0 x 50 mm, part number