9conditioner operation, 1roll and feed draper speed, 2adjusting roll gap – MacDon HC10 for D-Series User Manual

Page 88: Conditioner operation, Roll and feed draper speed, Adjusting roll gap, Warning, 9 conditioner operation

4.9

Conditioner Operation

WARNING

Keep hands and feet away from discharge opening. Keep everyone several hundred feet away from

your operation. Never direct the discharge toward anyone. Stones or other foreign objects can be

ejected with force.

WARNING

To avoid bodily injury or death from unexpected startup of machine, stop engine and remove key before

adjusting rolls.

4.9.1

Roll and Feed Draper Speed

The roll and feed draper speeds change whenever the header knife speed is changed since the drives use the same

hydraulic circuit. They cannot be independently adjusted.

4.9.2

Adjusting Roll Gap

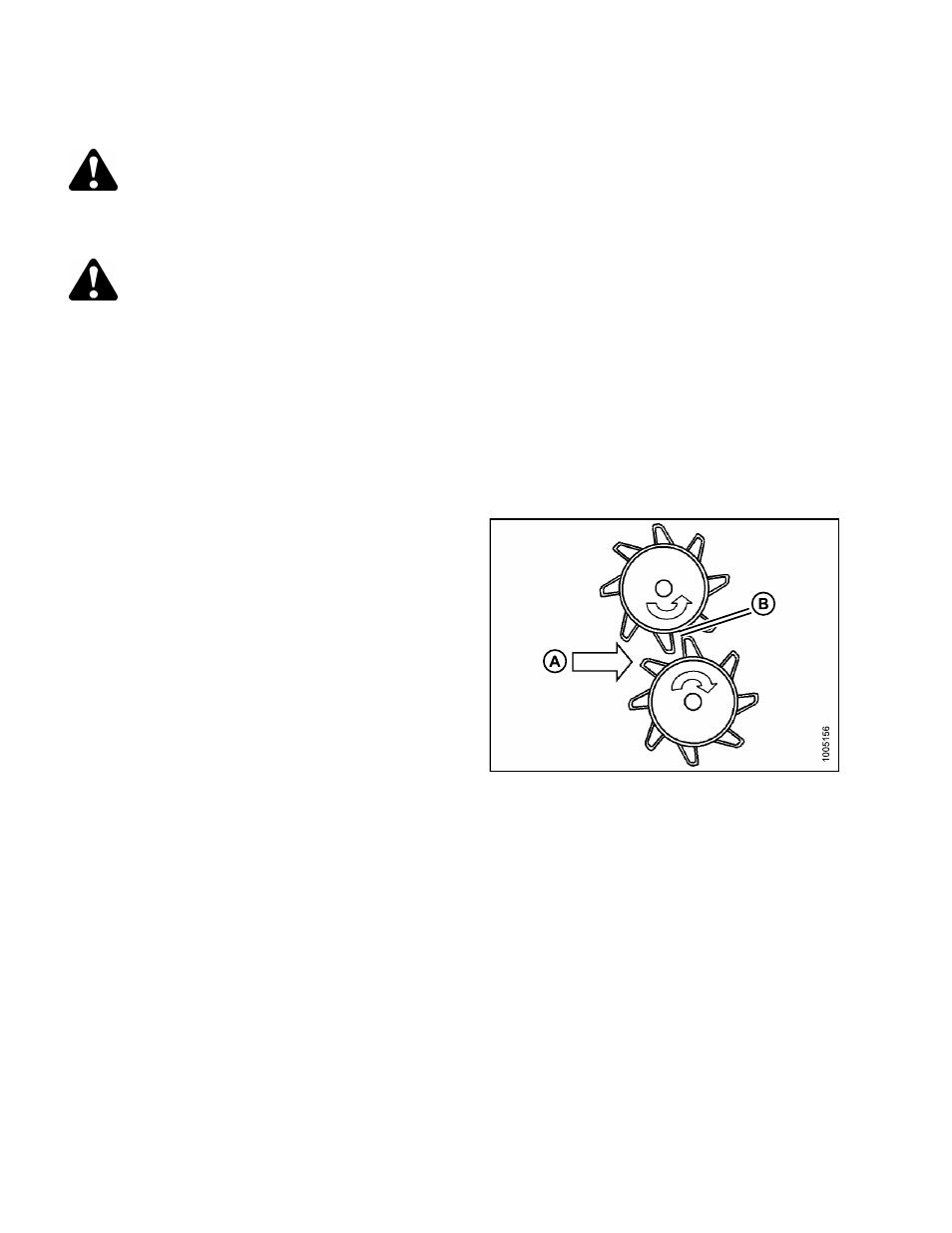

Steel rolls condition the crop by crimping and crushing the

stem in several places. This allows moisture release for

quicker drying. The degree to which the crop is conditioned

as it passes through the rolls is controlled by roll gap. See

illustration. The gap is factory set at 0.75 in. (20 mm) or at

1.5 line on gauge. Gauge readings should be the same at

both ends of the roll.

Correct conditioning of alfalfa, clover and other legumes is

usually indicated when 90% of the stems show cracking,

but no more than 5% of the leaves are damaged. Use only

enough roll gap to achieve this result.

A larger gap (up to 1 inch [25 mm]) may be desirable in

thick-stemmed cane-type crops; however, too large a gap

may cause feeding problems.

Grass type crops may require less gap for proper feeding

and conditioning.

The intermeshing steel rolls of the

hay conditioner crimp the plant stems in several places,

allowing moisture release and quicker drying.

Figure 4.31

A - Crop Direction

B - Roll Gap

169254

80

Rev. D