Lenze ApplicationTemplate PackML (PLC Designer R3-x) User Manual

Page 70

Architecture: The ApplicationTemplate PackML in detail

State machine in detail

70

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

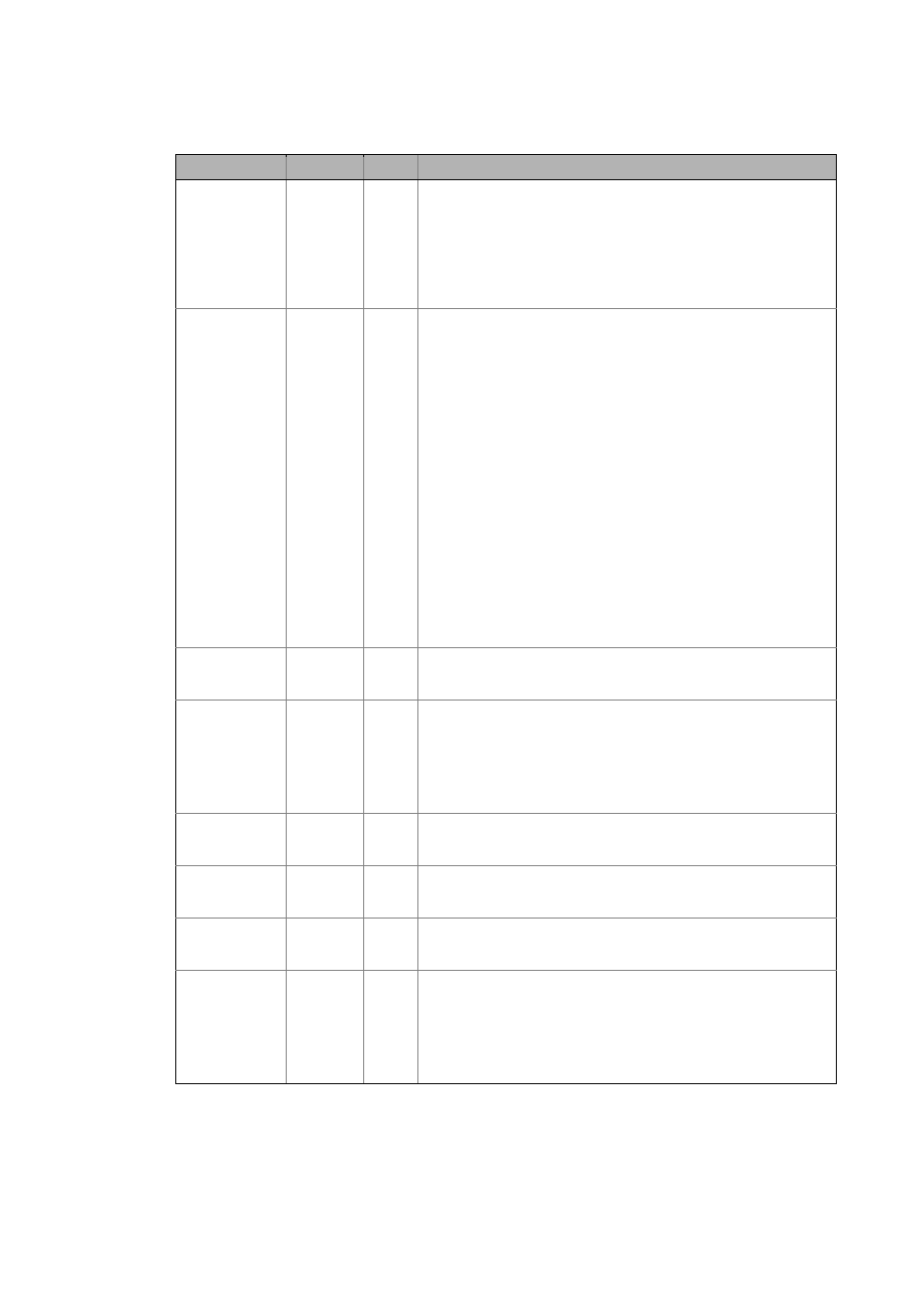

HELD

Waiting

Yellow This state is reached as described for the HOLDING state. In the HELD

state, the machine is stopped either by a complete stop or by a

continuous "dry running".

• As soon as the INTERNAL machine state changes/the operator

triggers the UNHOLD command, the machine changes to the

UNHOLDING state.

• Usually, the Performance Management/OEE system considers the

HELD state (waiting for the entry of the operator) as "not available".

HOLDING

Active

green

This state is reached if INTERNAL machine states causes the production

of the machine to stop. This means that the machine leaves the EXECUTE

state due to an INTERNAL trigger/state.

• Usually, the HOLDING state takes place in case of regularly occurring

machine states that require an action of the operator in order that

the machine is able to continue the production.

• The HOLDING state can be automatically or manually triggered/

retracted again by the operator. The regular filling of material, for

instance, needs an action of the operator, as the filling of adhesive

dispensers or cardboard storages. This may be required if due to the

mechanical construction of the machine a certain action is only

possible when the machine is stopped.

• Filling up material is a regular working sequence in the production

process. Thus, it is an integral part of the machine. (If it was an

external part, this subfunction would bring the machine to a

standstill by ABORTING/STOPPING). Usually the machine is stopped

in a controlled manner in the HOLDING state and then changed to the

HELD state.

• In order to restart the machine in a controlled manner after the HELD

state, all relevant process setpoints/return states of the procedures

have to be saved that are available at the time of the HOLD command

in the machine control.

IDLE

Waiting

Yellow This state indicates that the RESETTING has been completed. The IDLE

state keeps the current state of the machines that have been reached

during RESETTING state and executes the requested operations.

RESETTING

Active

green

This state is active after the RESET command has been triggered in the

RESET/STOPPED state.

• Error and stop events are reset.

• Usually, the RESETTING state safety appliances. The machine changes

to the IDLE state to wait for the START command. This ensures that

the machine does not carry out any dangerous movements in this

state.

STARTING

Active

green

This state comprises the steps required for starting the machine and is

caused by a START command. After a successful start: Change to the

EXECUTE state.

STOPPED

Waiting

Yellow After the STOPPING state has been left, the machine is switched on and

at standstill. The communication with other systems is fully functional.

The RESET command triggers the change to the RESETTING state.

stopping

Active

green

This state carries out steps that stop the machine in a controlled manner,

see STOPPED state. The machine cannot be started again until a restart

is executed.

SUSPENDED

Waiting

Yellow This state is reached as described for the SUSPENDING state. In this state,

the machine stops either by a complete stop or by continuously moving

without producing until the external state has normalised.

• Typically, the state changes from SUSPENDED to UNSUSPENDING

without the operator having to trigger a command.

• Usually, the Performance Management/OEE system considers the

SUSPENDED state (blockade/supply shortfall) as "available".

State

Category

Colour

Description