8 appendix, 1 communication by means of opc, 1 basics of the opc standard – Lenze Controller-based Automation User Manual

Page 60: Appendix, Communication by means of opc, Basics of the opc standard, 8appendix

8

Appendix

8.1

Communication by means of OPC

60

Lenze · Controller-based Automation · System Manual · DMS 1.4 EN · 04/2014 · TD17

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

8

Appendix

8.1

Communication by means of OPC

OPC is a standardised software interface for manufacturer-independent communication in

automation technology. OPC stands for Openness, Productivity, Collaboration (formerly "OLE for

Process Control"). The target is to exchange data between different software applications.

8.1.1

Basics of the OPC standard

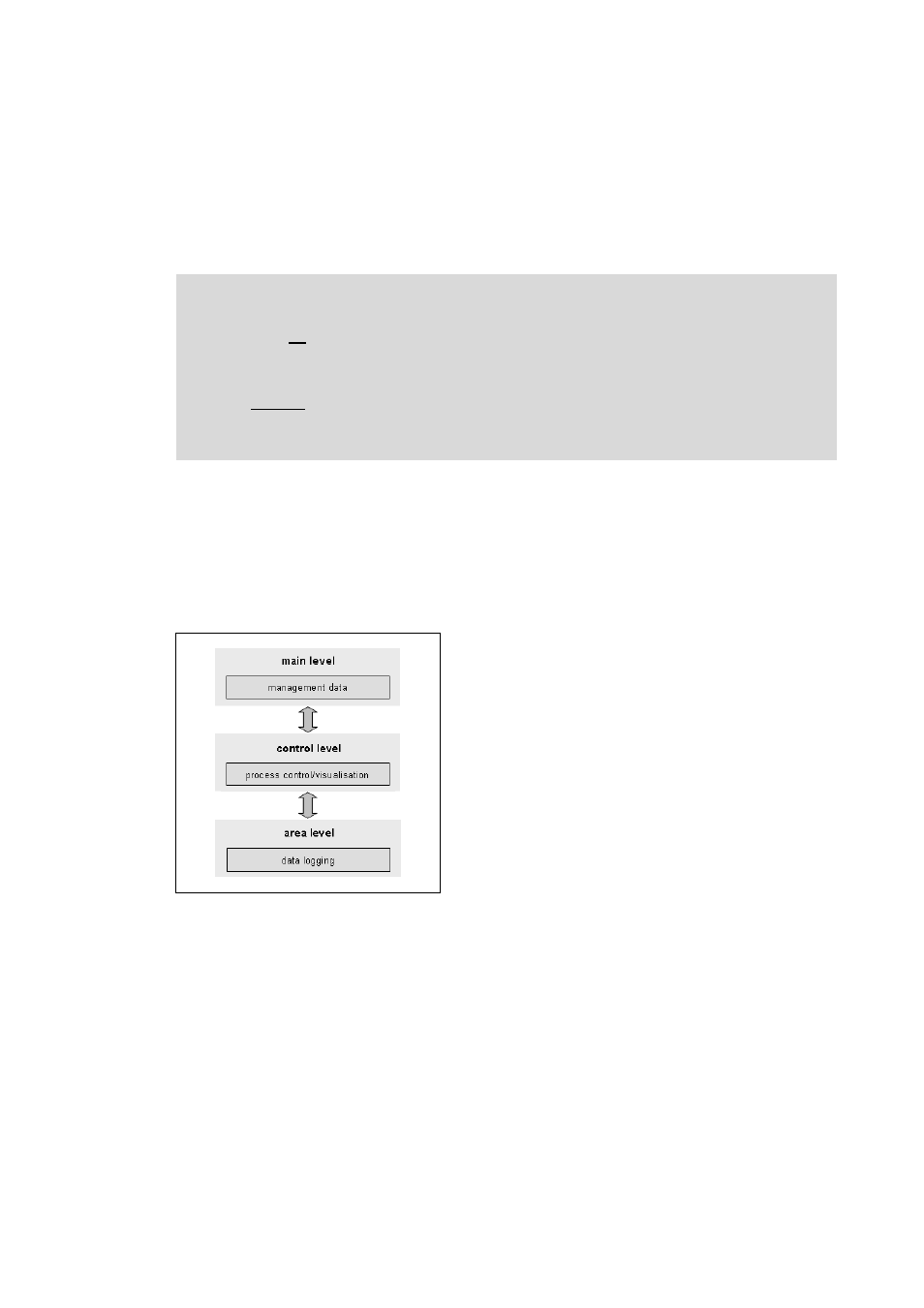

Industrial operation in the field of automation technology can be divided into three levels:

• In the master level and control level, mainly PC components are used.

• The field level consists of hardware in the form of sensors and actuators.

The task of PC-based automation solutions is to implement suitable process integration, in order to

enable access to the data of the field level.

For a conventional automation solution, data exchange with PC-applications requires a specific

driver in each case, each hardware requiring an individual driver. Thus the corresponding software

application has to be adapted to each hardware component. The OPC standard simplifies

communication between the Engineering PC and the controller as well as access to data of the field

level.

Note!

There is no OPC server available for PROFIBUS and PROFINET.

Controller c300/p300:

• The OPC communication for »VisiWinNET« is exclusively available for Controller p300

without PLC.

• Otherwise, only the Lenze "Logic&Motion" direct driver can be used for the data

exchange between »VisiWinNET« and PLC.

1. The master level visualises and manages the

visualisation data.

2. The control level controls the processes and

manages the process data.

3. The field level collects data and provides the

measured values.